Mold and bottom pressure grouting system for gel casting ceramic slice

A technology of injection molding and ceramic flakes, which is applied in the direction of die-casting molds, ceramic molding machines, manufacturing tools, etc., to achieve good sealing, avoid air bubbles, improve the speed and uniformity of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

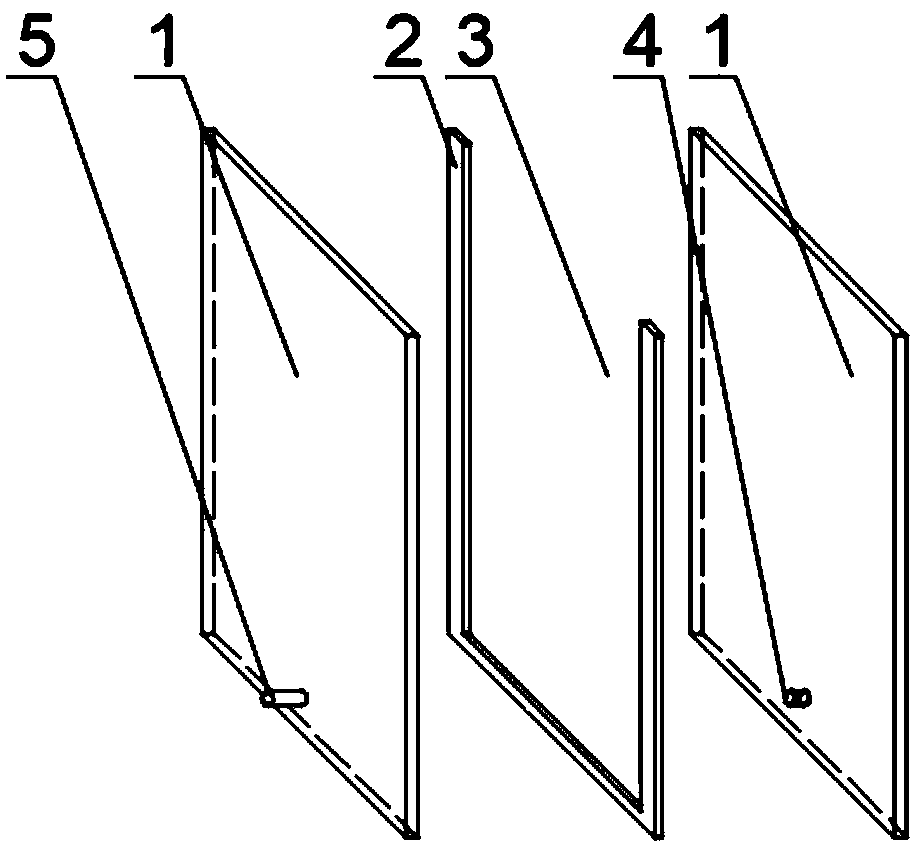

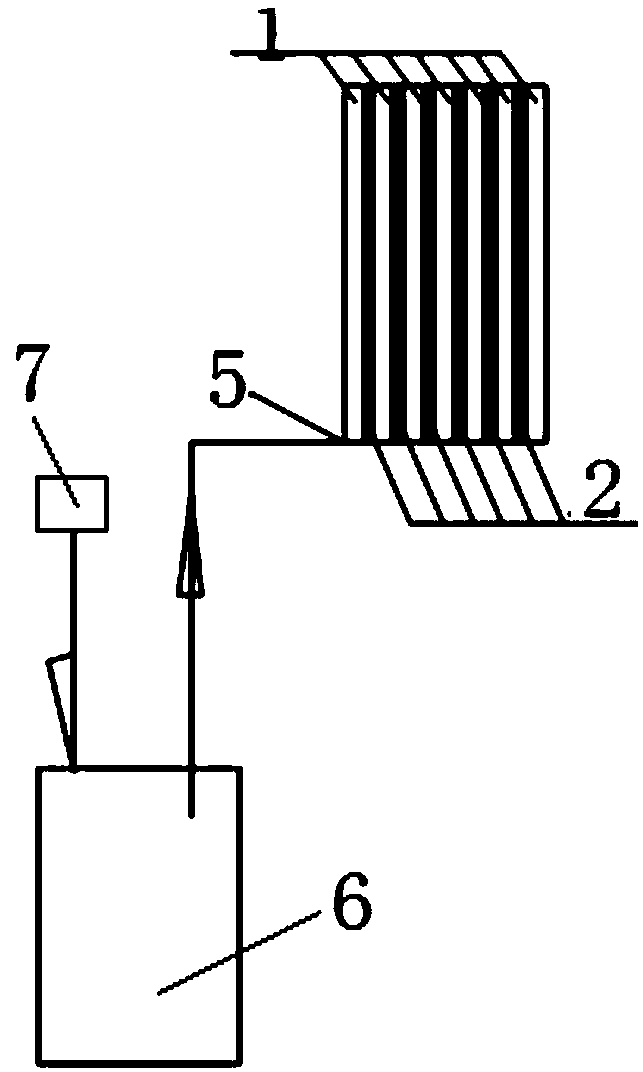

[0024] The present invention claims to protect a mold for gel-casting ceramic sheets, which includes partitions 1, gaskets 2 are arranged between adjacent partitions 1, the gaskets 2 are U-shaped, and the adjacent partitions A grouting mold cavity 3 is set between the plate 1 and the U-shaped gasket 2, and the partition 1 is sealed with the bottom of the gasket 2 and the bottom of the grouting mold cavity 3. The grouting channel 4 of the cavity 3 communicates with the grouting port 5 provided on the partition 1 .

[0025] Preferably: the material of the separator is glass.

[0026] Preferably: the separator 1 is square. Further, the width of the U-shaped spacer 2 is the same as that of the square.

[0027] In the prior art, the method of injecting slurry from the top of the gel-casting-shaped ceramic sheet will generate a large number of air bubbles, so that there are many defects in the formed ceramic green sheet, especially for the green sheet with a thickness of less than...

Embodiment 2

[0029] The features of this embodiment that are the same as those of Embodiment 1 will not be repeated here. The difference between this embodiment and the above embodiments is that the number of the grouting port 5 is one, and the shape of the grouting port 5 is circular.

[0030] The circular grouting port 5 is conveniently connected with the pipeline from the slurry tank 6 in a sealed manner, which improves the sealing performance of the mould.

Embodiment 3

[0032] The characteristics of this embodiment that are the same as those of Embodiment 1 or Embodiment 2 will not be repeated here. The difference between this embodiment and the above embodiments is that the grouting channel 4 is parallel to the bottom surface of the mould.

[0033] Preferably: the grouting channel 4 is located at the same height as the mold, and the height of the spacer 2 is smaller than that of the partition.

[0034] Preferably: the U-shaped gasket 2 is also provided with a grouting channel 4 .

[0035] The setting of these technical features improves the flow velocity of the slurry in different grouting channels 4 and mold cavities, and improves the efficiency of grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com