Lifting device for painting spraying of front shaft of automobile forge piece

A lifting device, forging technology, applied in the direction of injection device, etc., can solve problems such as low work efficiency, and achieve the effect of improving work efficiency, reasonable structure design and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

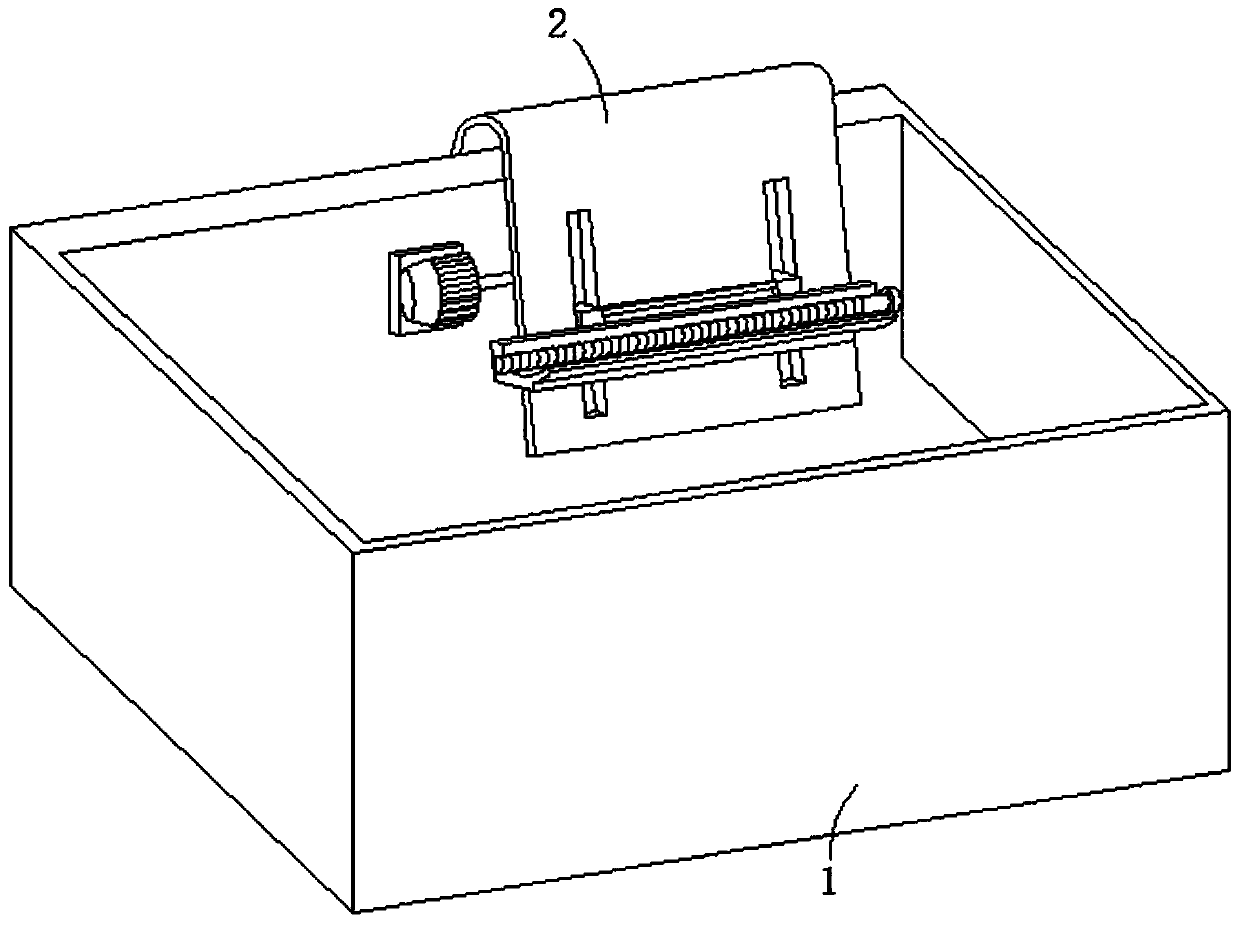

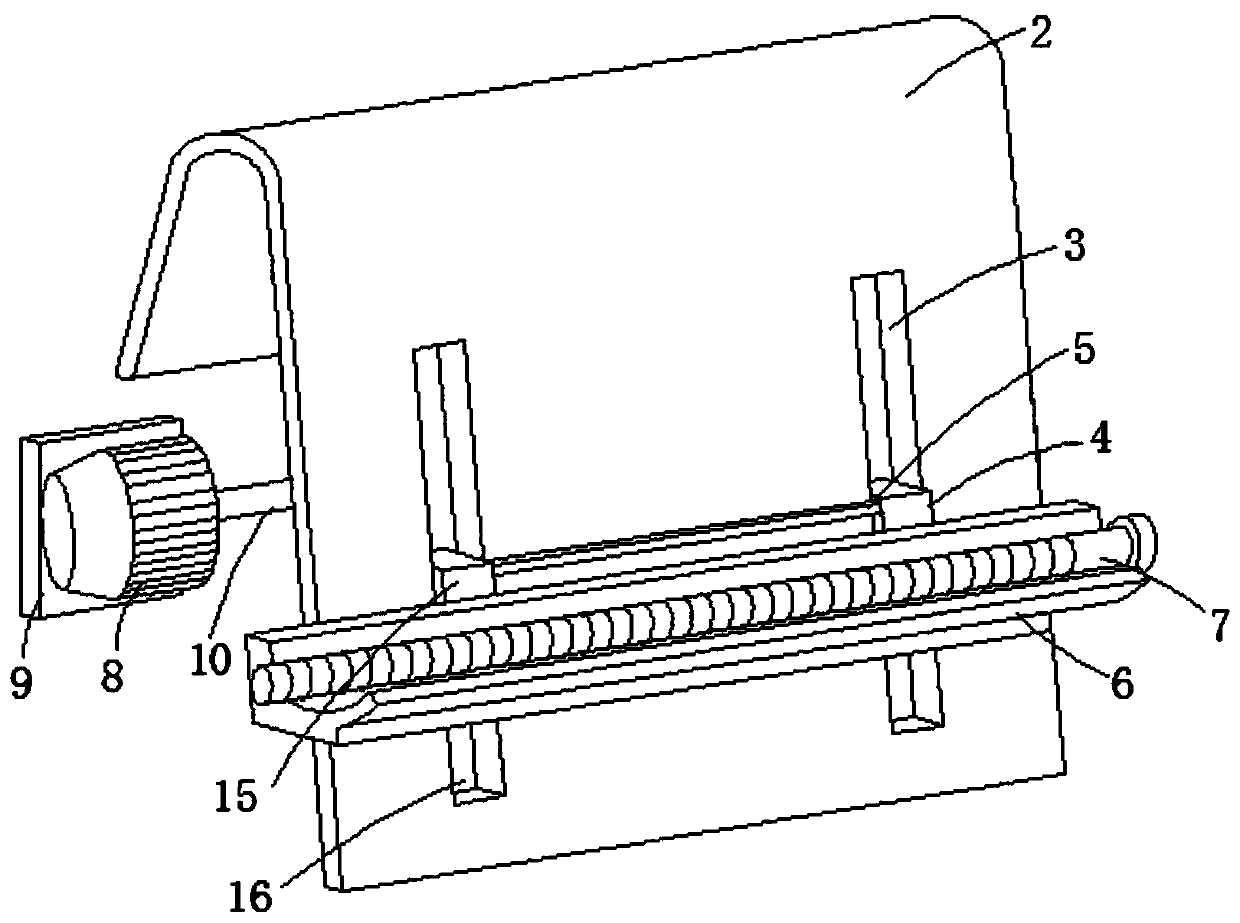

Embodiment 1

[0033] Such as Figure 1-4 As shown, in this embodiment, a lifting device for painting and spraying the front axle of automobile forgings is proposed, which includes a spraying support frame 1 and a cooling assembly. The cooling assembly includes a support frame 2 and a drive motor 8. The first moving through hole 3 and the second moving through hole 16, and the first sliding block 4 and the second sliding block 15 are slidingly arranged in the first moving through hole 3 and the second moving through hole 16 respectively, and the first sliding block 4 It is connected with the second sliding block 15 through the connecting rod 5, and the first sliding block 4 and the second sliding block 15 are jointly connected with a placement groove 6, and the forging body 7 is placed on the placement groove 6, and the driving motor 8 is fixedly arranged On the fixed plate 9, and the fixed plate 9 is fixedly arranged in the spraying support frame 1, the driving part of the driving motor 8 i...

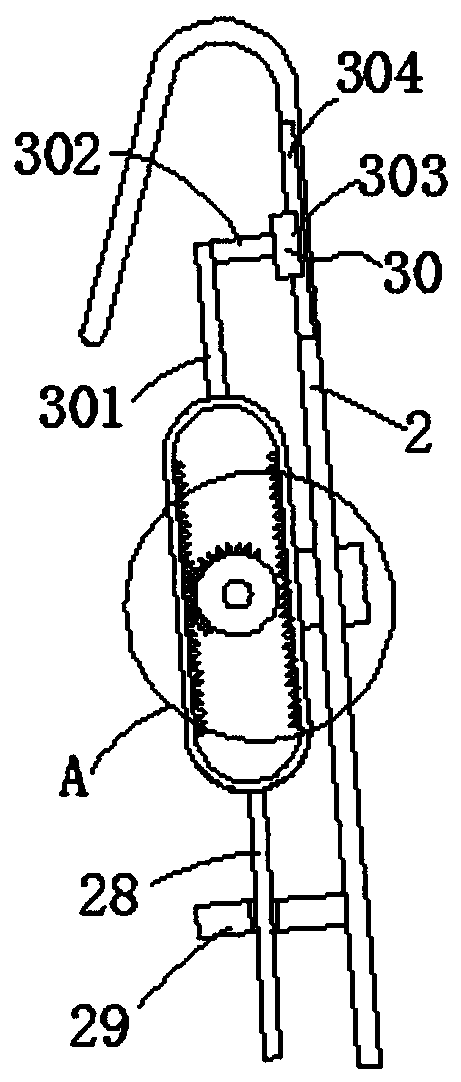

Embodiment 2

[0038] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, a guide assembly 30 is added, and the setting of the guide assembly 30 can be used to guide the movement of the ring gear 12 to ensure that the ring gear 12 Only move on the same trajectory, and the setting of the guide assembly 30 can also cooperate with the combination of the slide bar 28 and the support plate 29 to support the ring gear 12, so that the sliding bar 28 and the support plate 29 can be avoided. The combined force is too large, thereby delaying the service life of the combination of the sliding rod 28 and the support plate 29 .

Embodiment 3

[0040] Such as Figure 5 and Figure 6As shown, the difference between embodiment 3 and embodiments 1 and 2 is that in embodiment 3, a rotating assembly is added, and the setting of the rotating assembly is used to rotate when the forging body 7 moves up and down, and the rotation of the forging body 7 can be Accelerate the contact with the liquid paint, so as to improve the spray effect, specifically, the rotation process is as follows:

[0041] The up and down movement of the placement slot 6 will rotate with the first full gear 17 through the spur rack 14, and the rotation of the first full gear 17 will rotate with the first rotating rod 19, and the rotation of the first rotating rod 19 will pass through the conveyor belt 20. And the second rotating rod 21 rotates with the second full gear 22, the rotation of the second full gear 22 will bring the rotation of the third full gear 24 and the fourth full gear 26, so that the third full gear 24 and the fourth full gear are pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com