Range hood

A range hood and oil ring technology, applied in the field of range hood structure, can solve the problems of high noise of the range hood, and achieve the effects of improving efficiency, reducing pressure, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

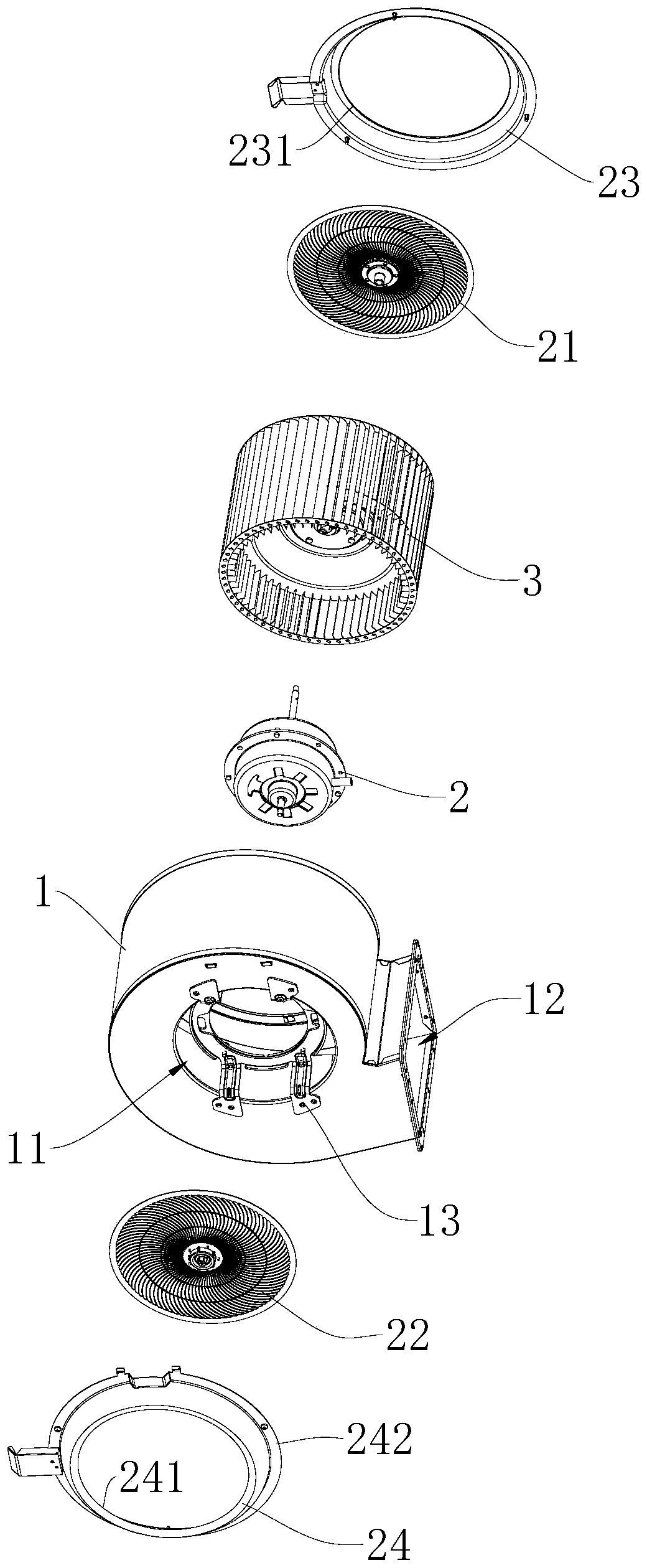

Embodiment 1

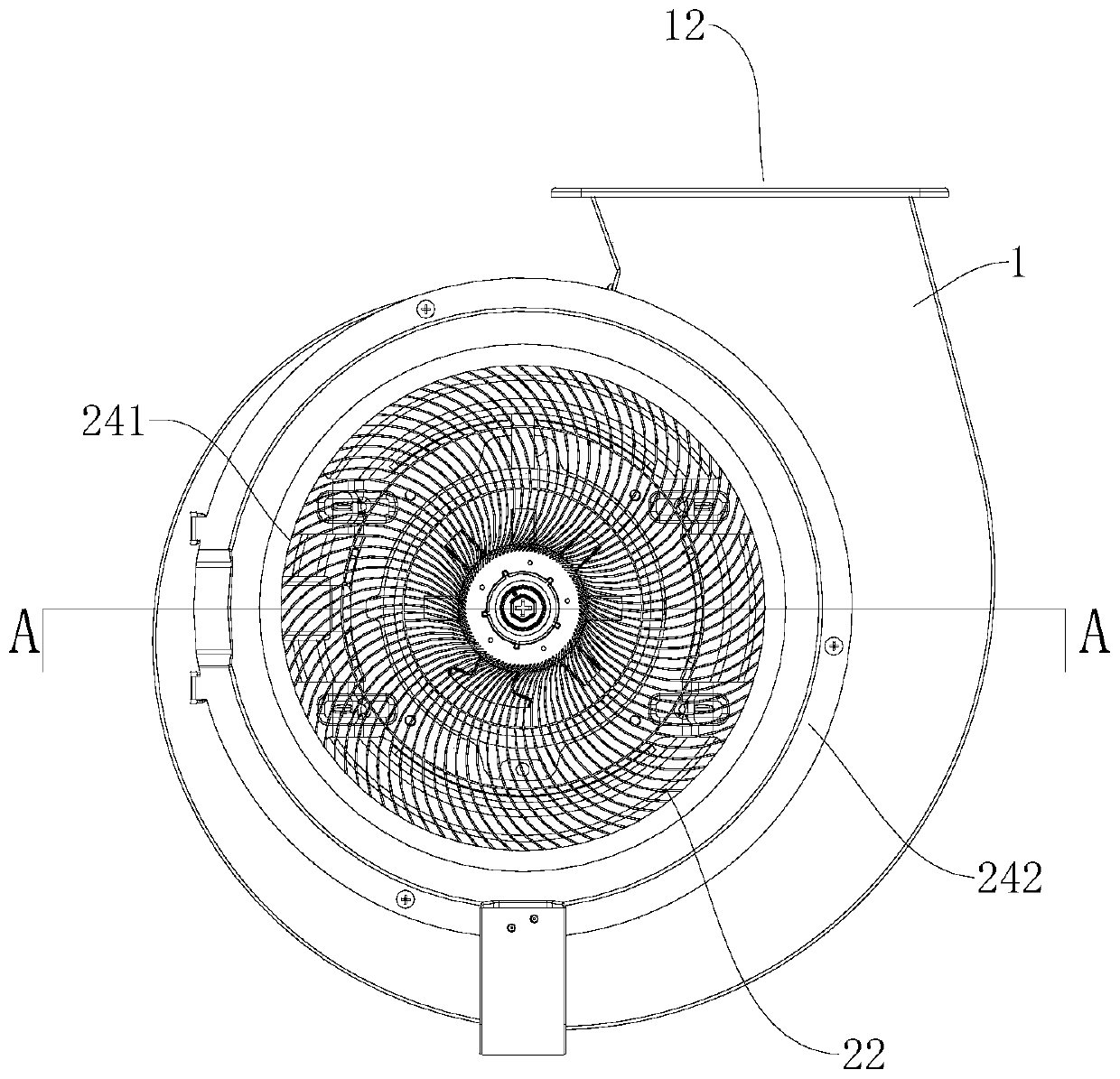

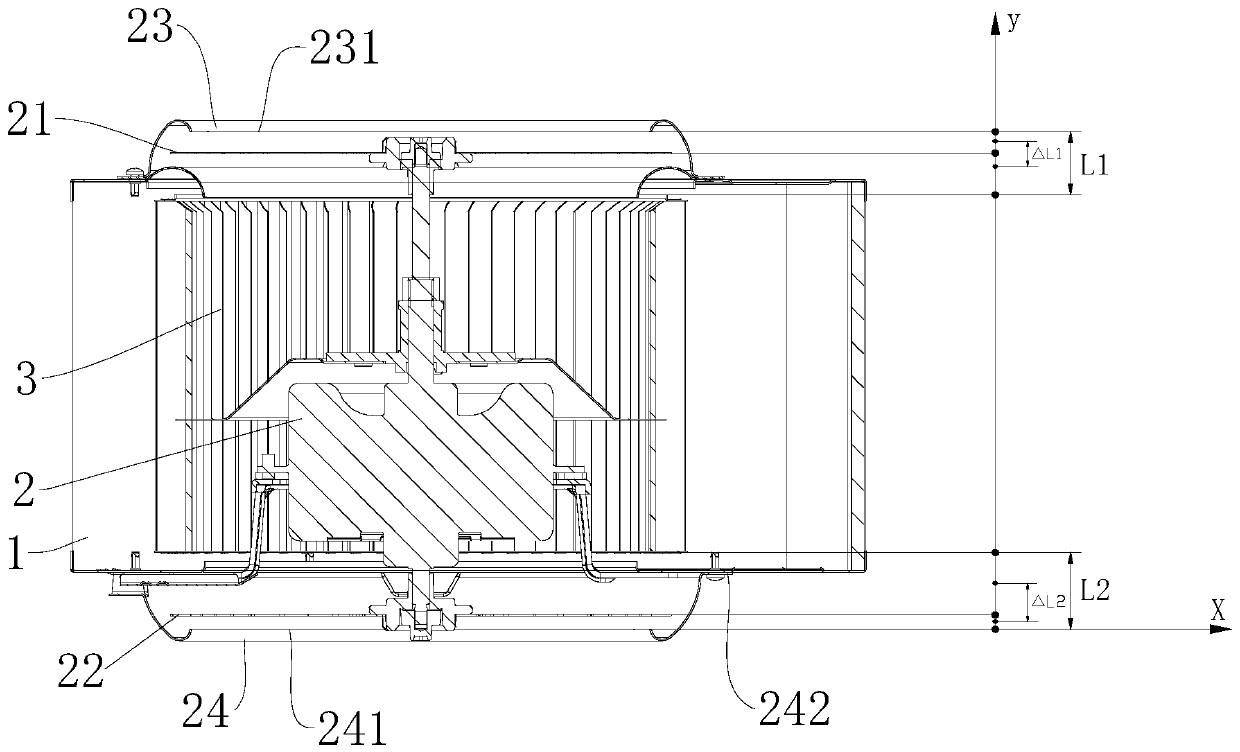

[0047] The range hood provided by the present invention includes: a front dynamic filter screen 21, which is arranged on the output shaft of the biaxial motor 2, and is located between the centrifugal fan wheel and the concave edge 231 of the front oil guide ring; The distance between the wheels is L1, and the value of the distance ΔL1 from the front dynamic filter screen 21 to the centrifugal wind wheel is [0.45L1, 0.85L1]. When the range hood was working, the air with soot sucked by the front oil guide ring 23 impacted on the front dynamic filter screen 21 through the guidance of the front oil guide ring concave edge 231. Part of the air is sucked into the volute assembly 1 through the mesh on the front dynamic filter screen 21 , and part of the air is blocked by the dynamic filter screen and moves around the dynamic filter screen along the surface of the dynamic filter screen. Wherein, the whole machine of the range hood has a shell, and the position of the dynamic filter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com