Method for eliminating outburst risk of two regional coal seams by using long bedding directional drilling holes

A technology for long drilling and coal seams, which is applied in earthwork drilling, gas discharge, safety devices, etc., and can solve problems such as high cost, time-consuming and labor-intensive, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

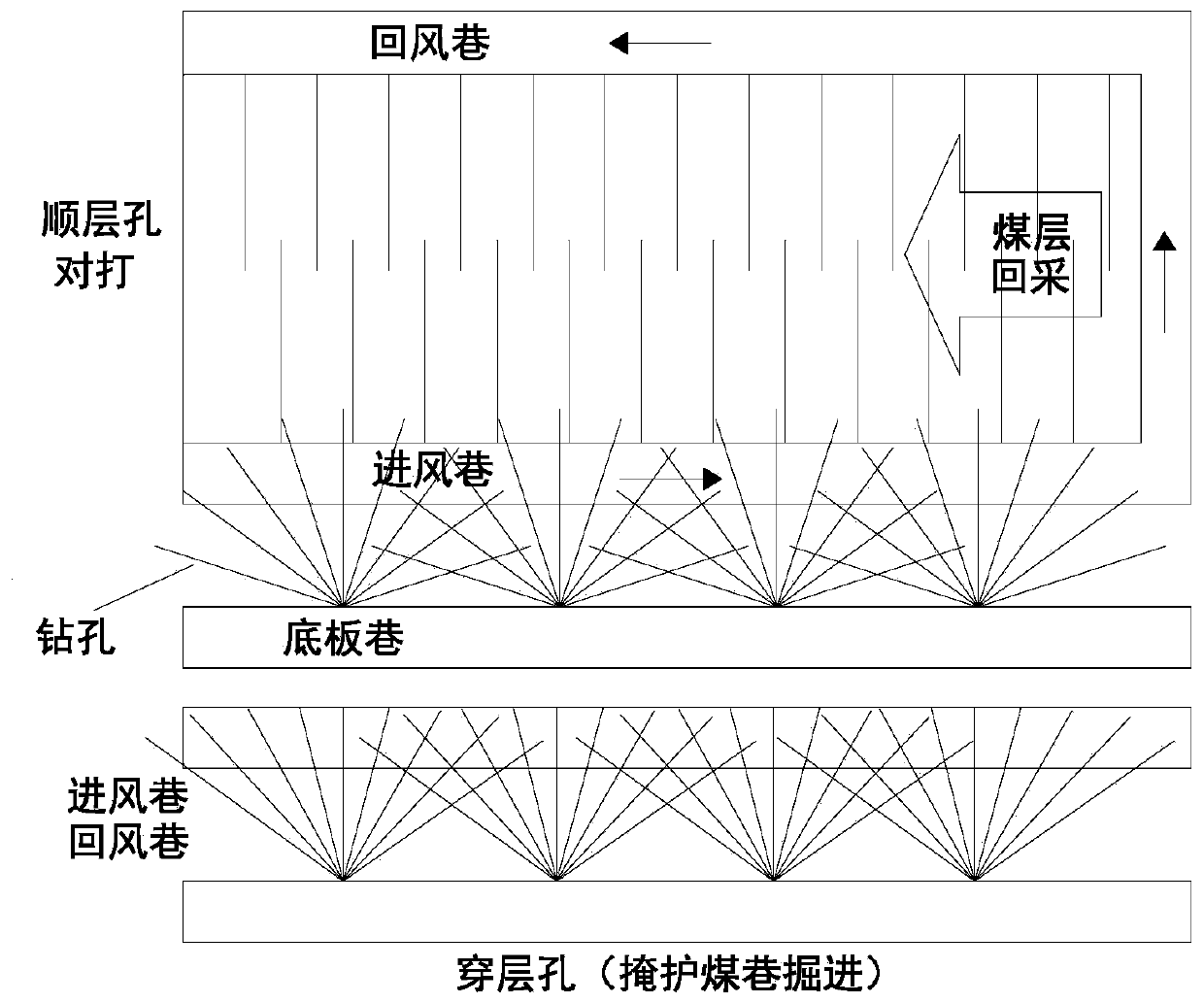

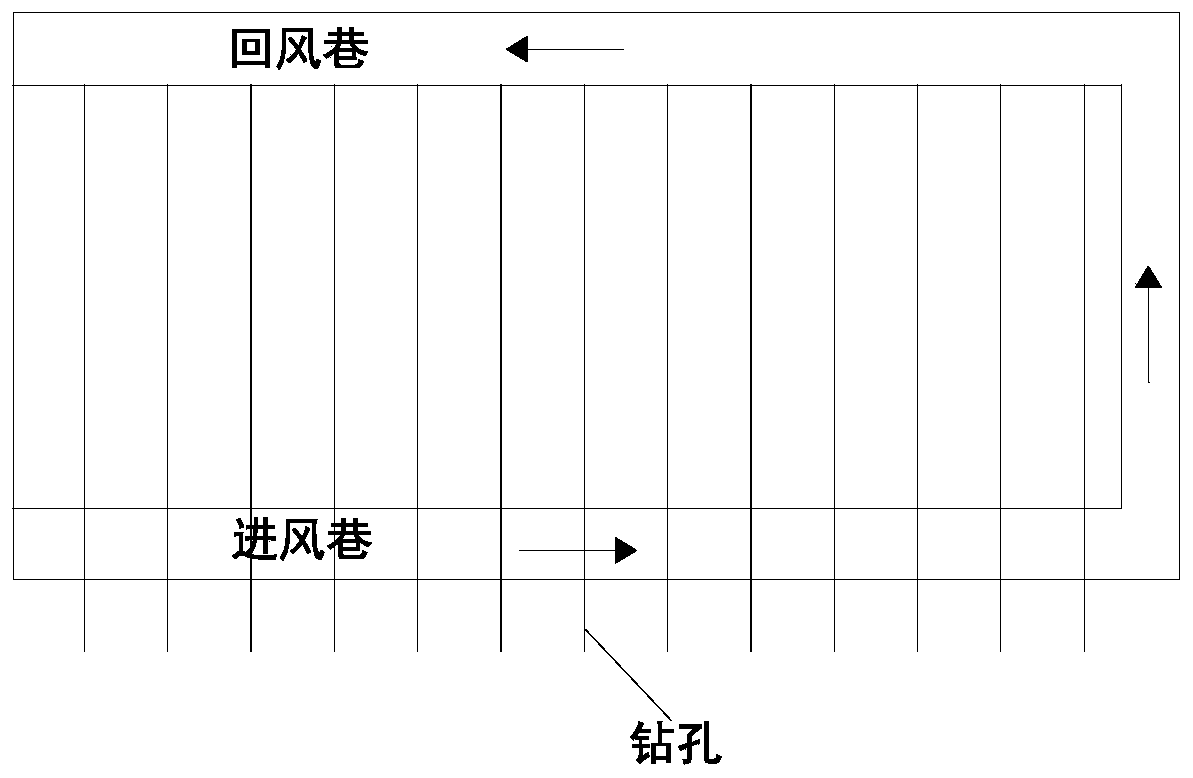

[0025] This embodiment discloses a method for eliminating the danger of coal seam outburst in two areas by directional long drilling along the bedding. A number of directional long drilling along the bedding is oriented by using a drilling rig in the backflow channel of the coal mining face. The boreholes all penetrate the coal seam in the mining area of the coal mining face and the strip coal seam of the coal roadway to be excavated; of gas. The schematic diagram of the method is shown in figure 2 shown.

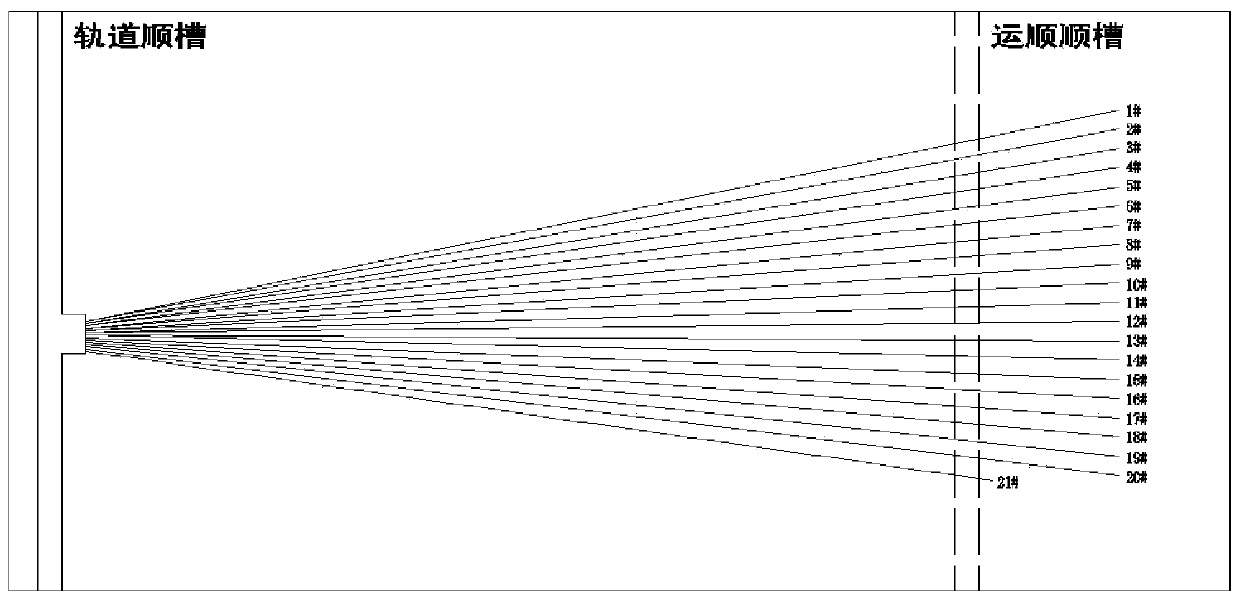

[0026] The following is an example of implementing the above-mentioned method of eliminating the danger of coal seam outburst in two areas by bedding directional long drilling in a working face of Pansan Mine in Huainan, and specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com