A friction mobile soft robot and its driving method

A friction-type, robotic technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of large size, inability to adapt to complex environments, low safety, etc., and achieve the effect of good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

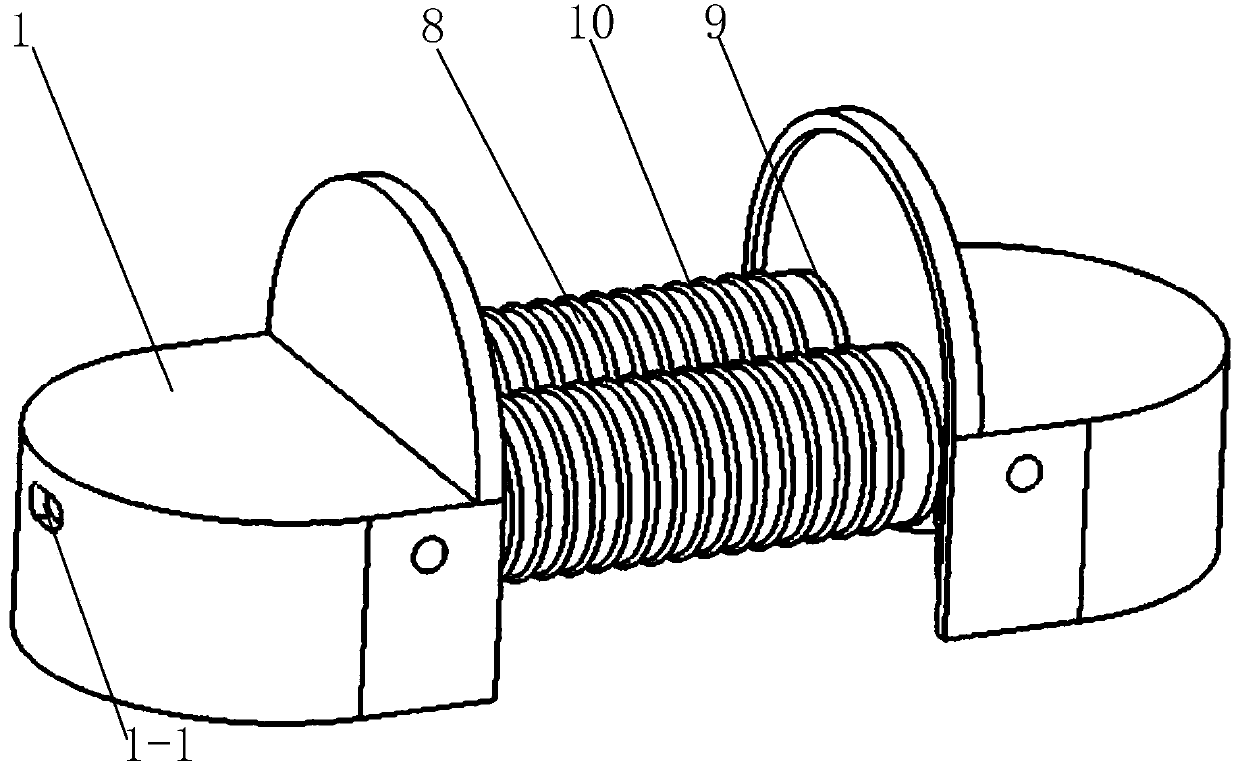

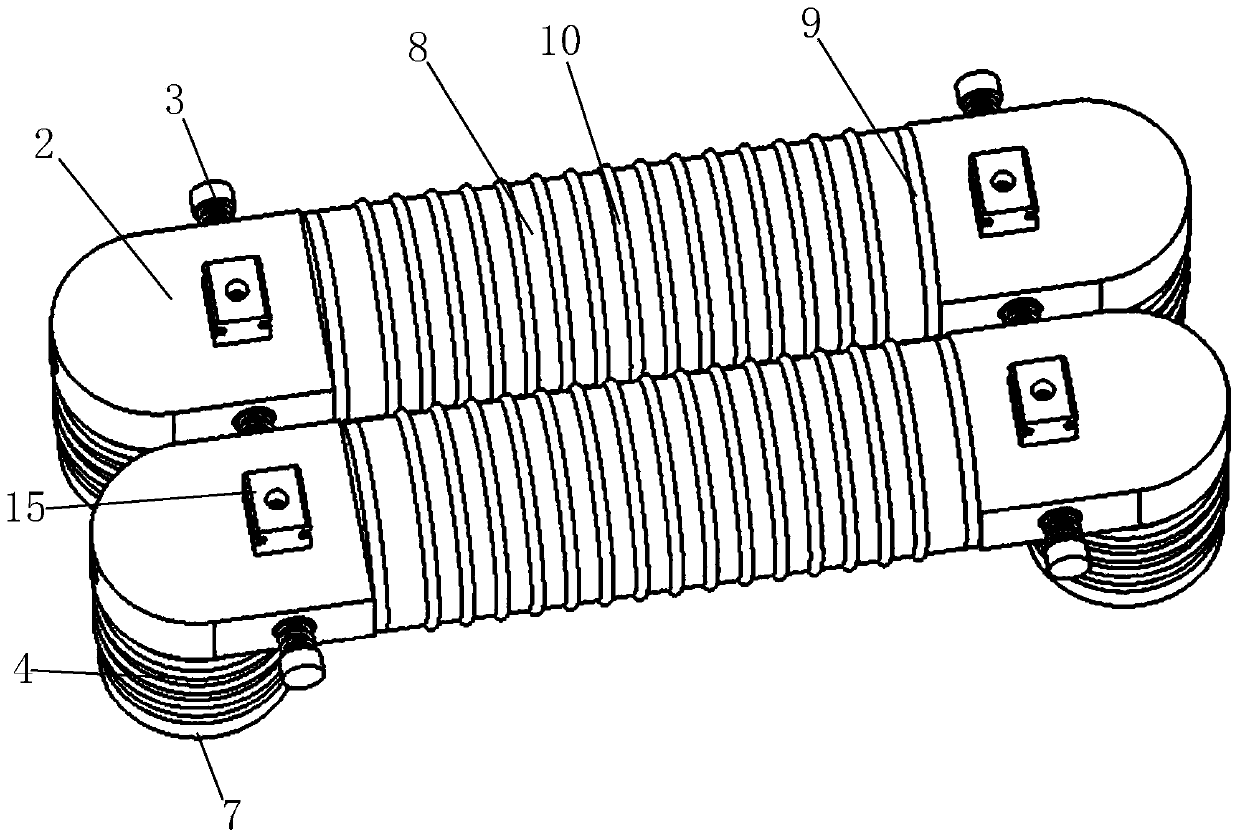

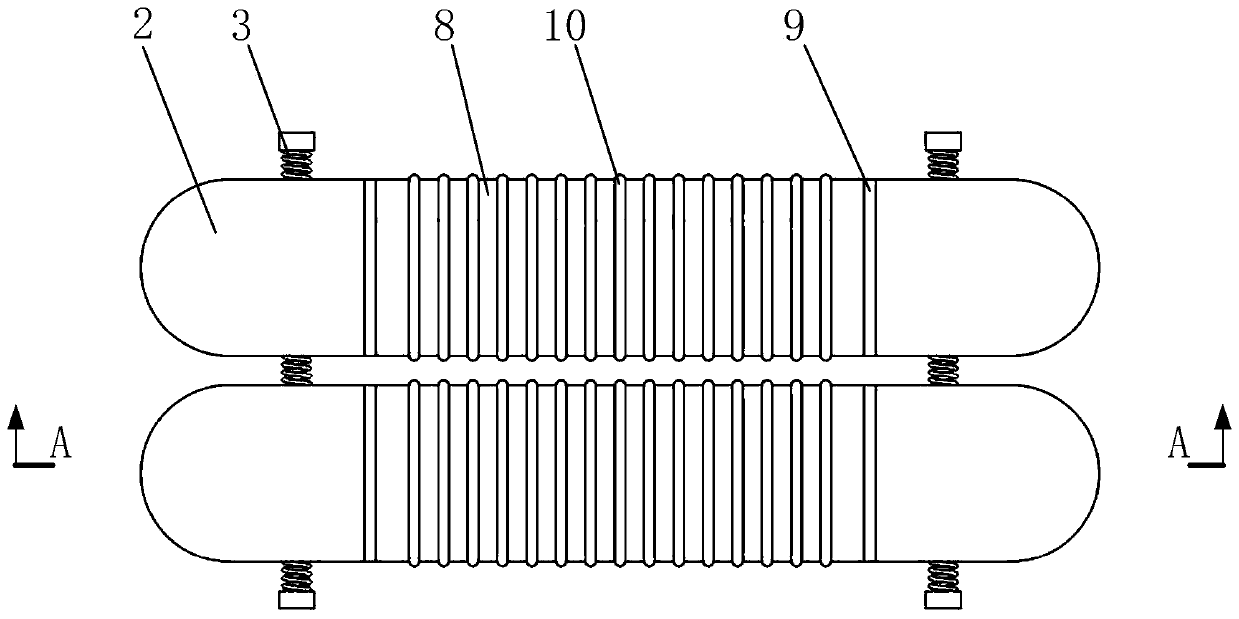

[0039] Such as figure 1 and 2 As shown, a frictional mobile soft robot includes end actuators, middle actuators, controllers and gas circuit parts. The end actuator includes an outer casing 1 , an end seat 2 , a spring 3 , an end air bag 4 , a first connecting plate 5 , a first limiting ring 6 , a cushion block 7 and a slider 15 . The outer shell 1 is the outer surface of the entire end actuator and is used to carry other components of the end actuator. The bottom of the outer casing 1 is open. Two end seats 2 are arranged side by side in the outer housing 1 . A slide rail is fixed on the top surface of the inner wall of the outer casing 1 . Slide blocks 15 are fixed on the top surfaces of the two end seats 2 . Both slide blocks 15 form a sliding pair with the slide rail. The axial direction of the slide rail is parallel to the arrangement direction of the two end seats 2 . Springs 3 are used to connect the two end seats 2 and between the two end seats 2 and the corresp...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that: a friction type mobile soft robot also includes a control box; the air source 11, the reversing valve 12, the on-off valve 13, the overflow valve 14 and the controller are all arranged in the control box Inside. The control box is connected with the end actuator provided with the main through-pipe hole 1-1 through an air duct. During the working process, the control box remains stationary, and the movement of the frictional mobile soft robot is controlled through the air duct, which makes the structure of the frictional mobile soft robot more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com