Full-automatic welding machine for automotive frame

A fully automatic technology for automobile girders, applied to vehicle parts, welding accessories, welding rod characteristics, etc., can solve the problems of inconsistent welding thickness of arc surface structures on both sides, inability to realize automatic flipping, and inability to realize automatic welding, etc., so as to improve welding quality , reduce the burden on workers and improve welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

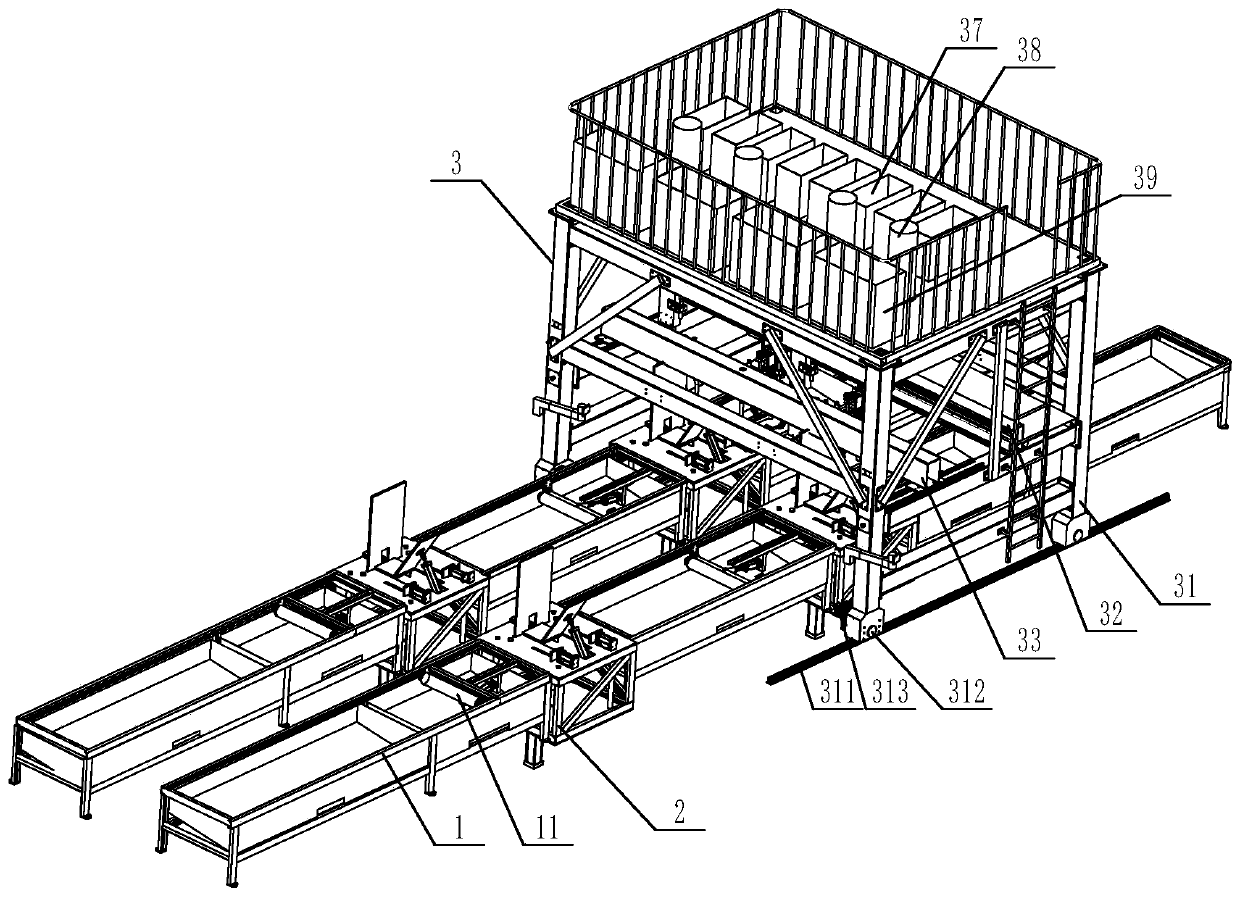

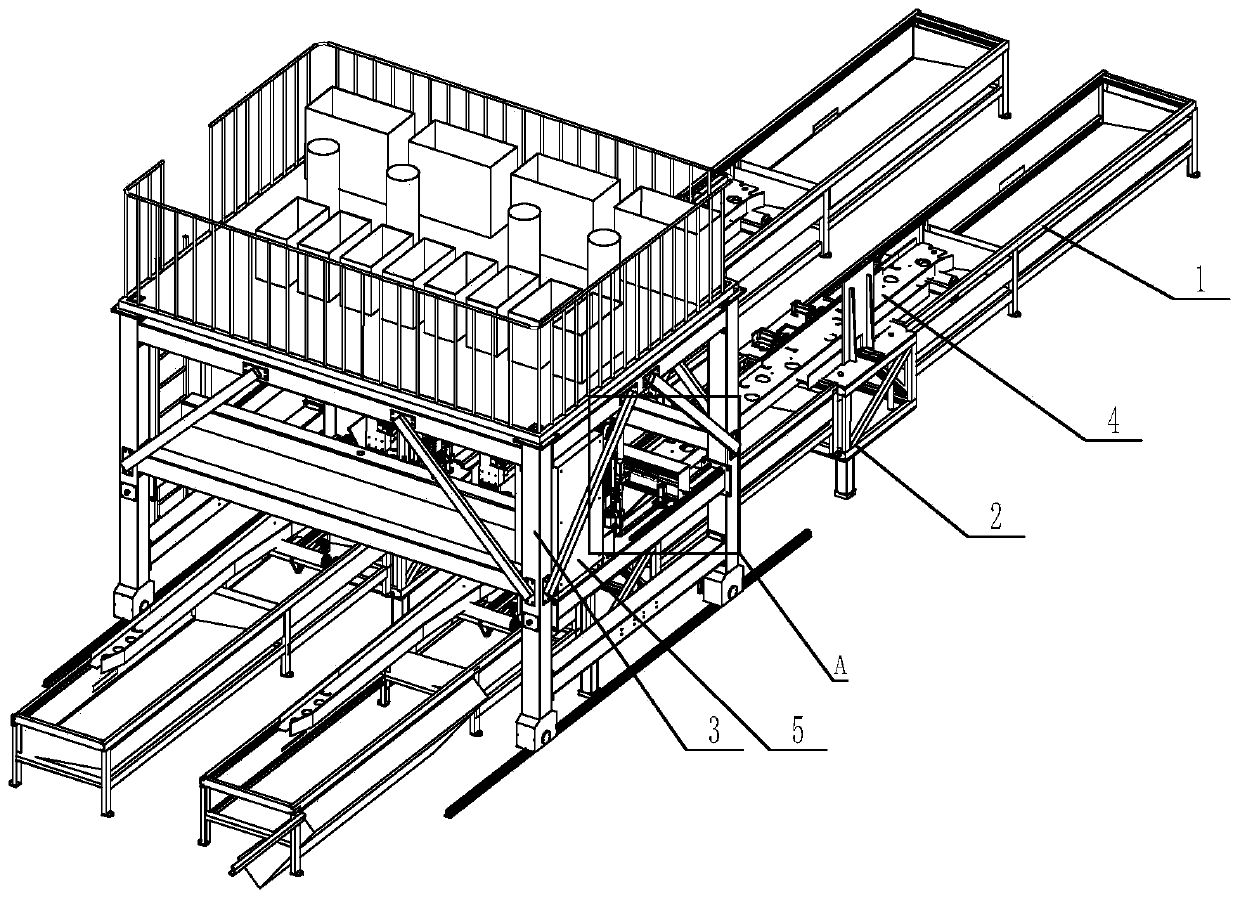

[0033] Embodiment one: if figure 1 As shown, the described automatic frame welding machine for automobiles includes a tooling frame 1, on which a roller 11 is arranged, and the roller 11 is convenient for adjusting the position of the frame workpiece 4; 1 An automatic welding device 3 that moves back and forth in the longitudinal direction. The automatic welding device 3 is provided with a fixed beam 32 and a movable beam 33 that can move back and forth along the length direction of the tooling frame 1. The fixed beam 32 and the movable beam 33 are respectively provided with more than one set of An automatic welding torch that can move left and right along the length direction of the movable beam 33.

[0034] Such as Figure 7 As shown, in the present embodiment, two groups of automatic welding guns are respectively arranged on the fixed beam 32 and the movable beam 33, which can realize simultaneous welding operations of two beam workpieces 4, and the automatic welding guns ...

Embodiment 2

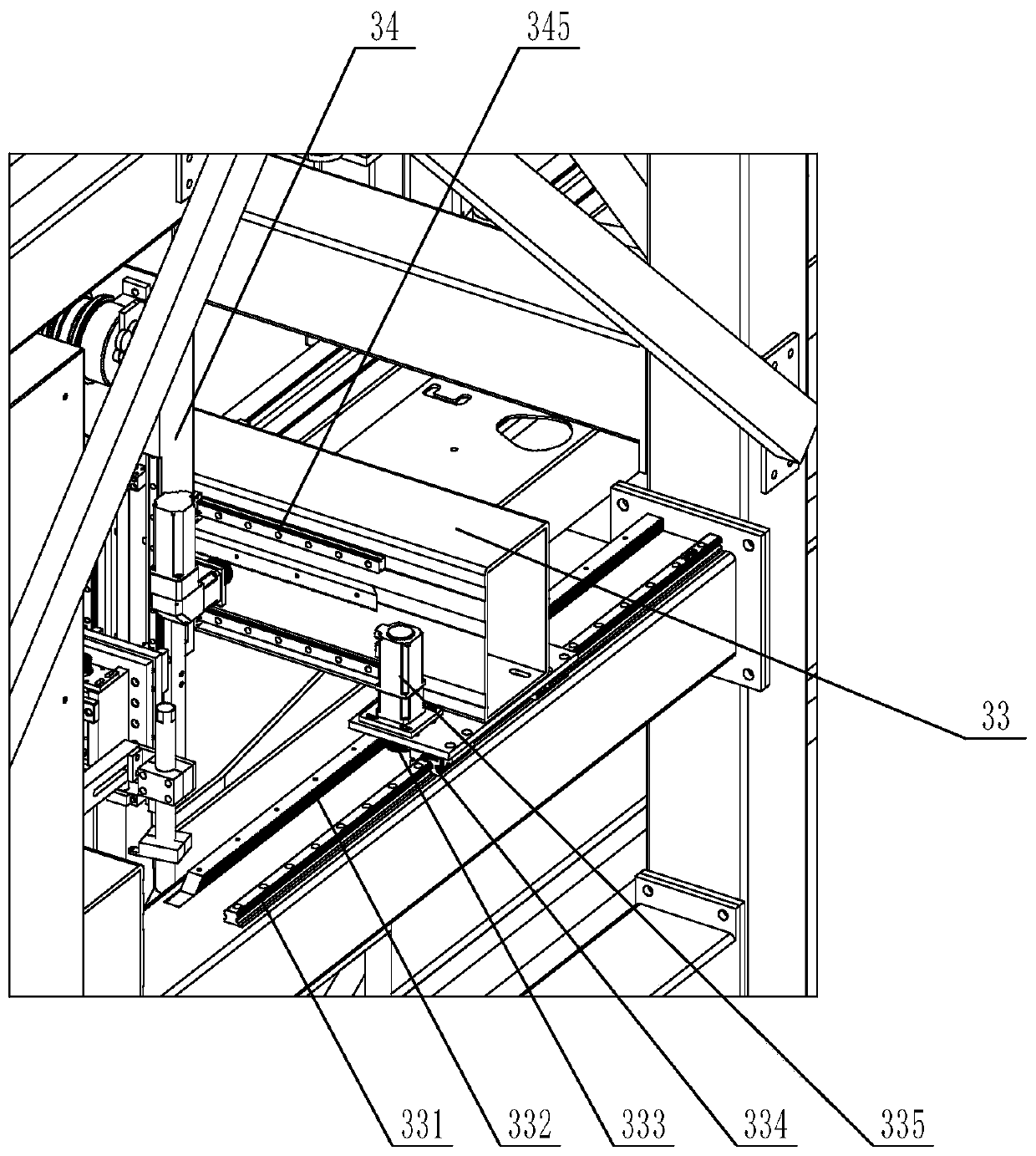

[0047] Embodiment 2: The supporting beam is provided with a second track 331, the bottom of the movable beam 33 is provided with a slide plate, the main body walking frame 31 is fixedly connected with an electric telescopic rod, and the protruding end of the electric telescopic rod is connected with the bottom of the movable beam 33; Others are the same as in Embodiment 1. The electric telescopic rod drives the movable beam 33 to move back and forth.

Embodiment 3

[0048] Embodiment three: the first track 311 is provided under the main body walking frame 31, the first track 311 is provided with a rack one, the bottom of the main body walking frame 31 is provided with a first motor 313, and the output end of the first motor 313 is provided with Gear one, gear one meshes with rack one; others are the same as embodiment one. The first motor 313 drives the main body walking frame 31 to move forward and backward through the cooperating gear one and rack one.

[0049] Such as figure 2 As shown, two beam workpieces 4 are respectively placed on the tooling frame 1, and the beam workpieces 4 are placed between the pushing cylinder 204 and the turnover plate 206 of the beam turning mechanism 2, and the position of the beam workpiece 4 is adjusted by the roller 11, so that Two beam workpieces 4 are on a horizontal line.

[0050] The present invention is also provided with distribution box, operation panel and PLC control module when making on ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com