Pipe drawing machine of centrifugal pipe casting machine

A technology of centrifugal casting and extubation machine, which is applied in the field of mechanical equipment, can solve the problems of lack of automatic core breaking function, low work efficiency, and low extubation efficiency, so as to improve extubation efficiency, strong stability, and avoid detachment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

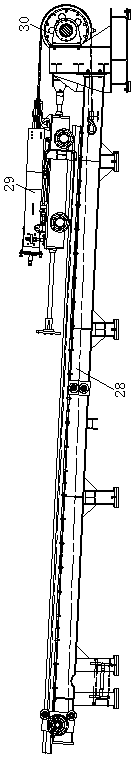

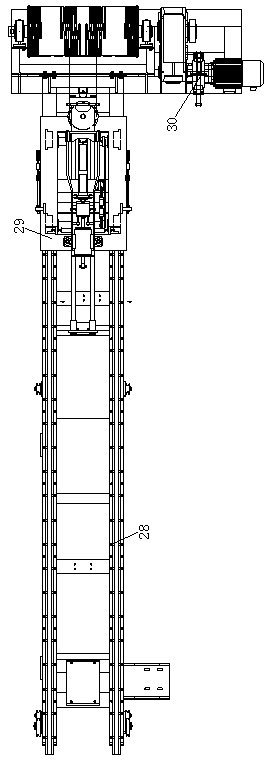

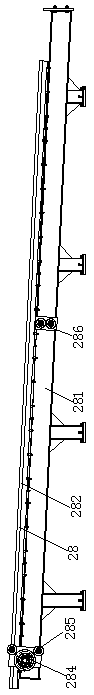

[0089] Example 1 (see Figure 1-13 ).

[0090] The extubation machine of the centrifugal pipe casting machine in the present embodiment comprises a track frame 28, an extubation car 29, an extubation drive device 30 and an extubation assembly, the extubation car 29 is connected with the extubation drive device 30, and the extubation car 29 and the extubation driving device 30 are all installed on the track frame 28, and the extubation assembly is installed on the extubation cart 29.

[0091] The extubation cart 29 in this embodiment includes a vehicle frame 291, wheels 292, extubation frame 293, extubation pulley 294, extubation rotating mechanism 295, extubation push-pull mechanism 296, extubation mechanism 297 and extubation adjustment mechanism 298, Extubation stand 293 is installed on the vehicle frame 291, and extubation pulley 294, extubation rotation mechanism 295 and extubation push-pull mechanism 296 are all installed on the extubation stand 293, and extubation rotat...

Embodiment 2

[0109] Example 2 (see Figure 1-11 , 14-15)

[0110] The extubation machine of the centrifugal pipe casting machine in the present embodiment comprises a track frame 28, an extubation car 29, an extubation drive device 30 and an extubation assembly, the extubation car 29 is connected with the extubation drive device 30, and the extubation car 29 and the extubation driving device 30 are all installed on the track frame 28, and the extubation assembly is installed on the extubation car 29.

[0111] The extubation cart 29 in this embodiment includes a vehicle frame 291, wheels 292, extubation frame 293, extubation pulley 294, extubation rotating mechanism 295, extubation push-pull mechanism 296, extubation mechanism 297 and extubation adjustment mechanism 298, Extubation stand 293 is installed on the vehicle frame 291, and extubation pulley 294, extubation rotation mechanism 295 and extubation push-pull mechanism 296 are all installed on the extubation stand 293, and extubation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com