Righting casing attaching and blocking pipe

A pipe plugging and casing technology, applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of uneven annular space, inability to install the erecting mechanism, thin wall thickness of the plugging pipe, etc., and achieve uniform cement sheath , Guarantee the quality of sticking and plugging, and the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

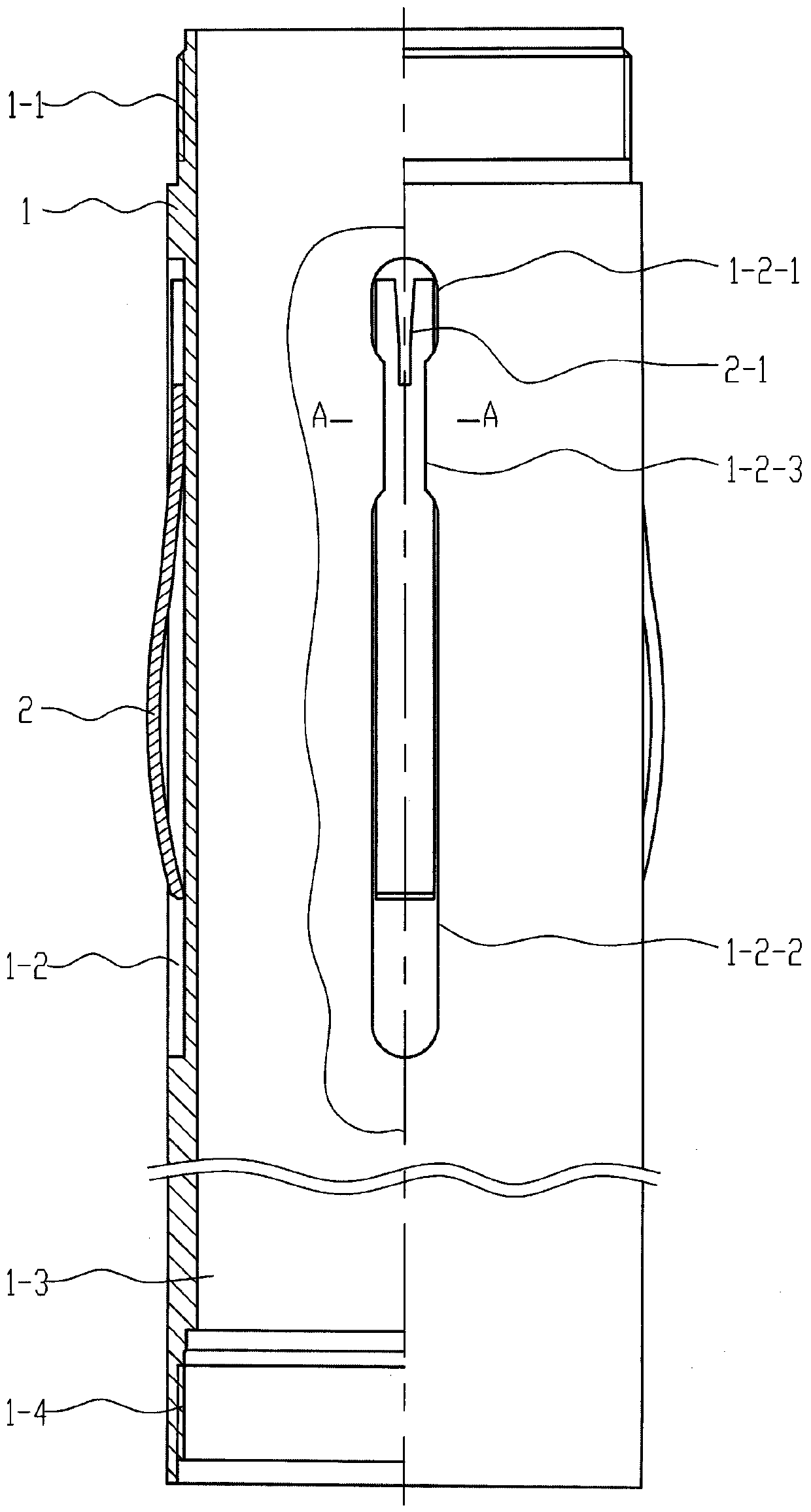

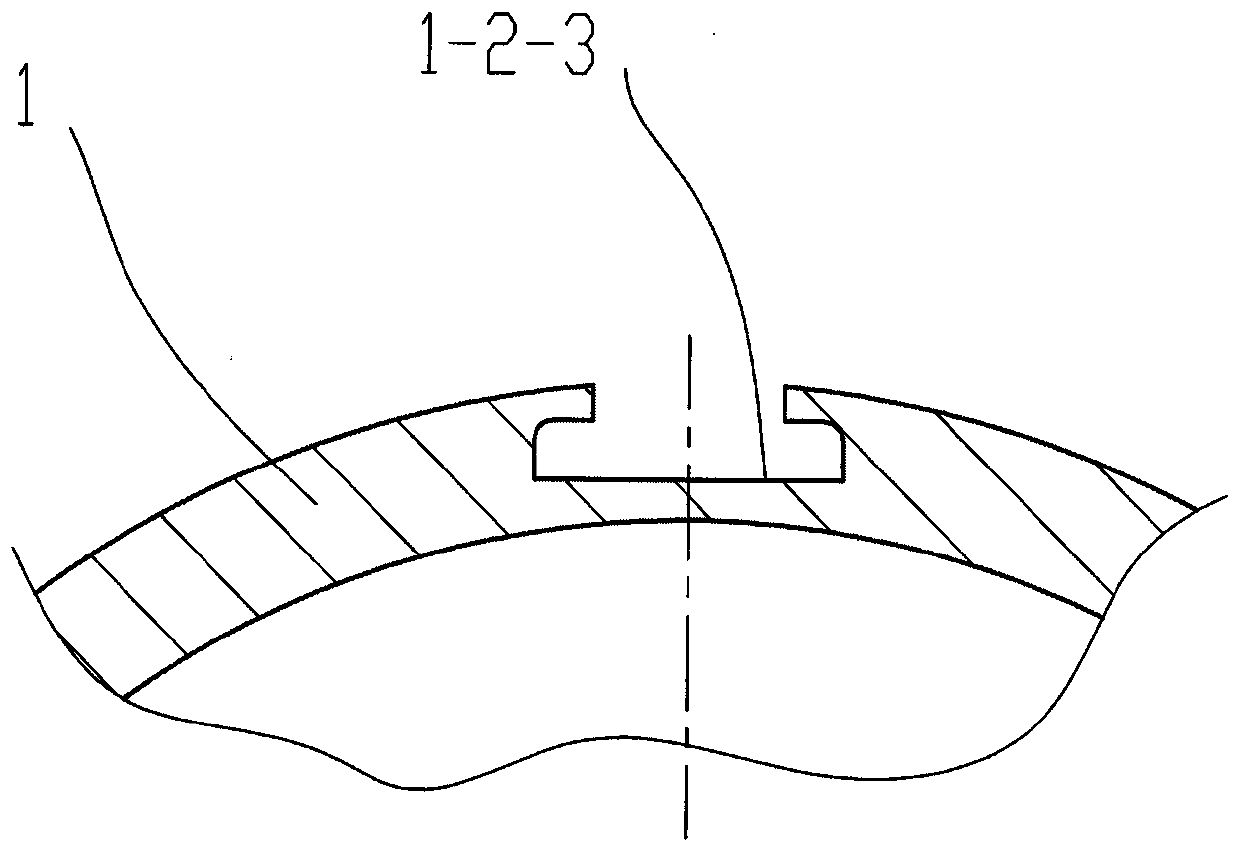

[0010] As can be seen from the figure, the embodiment of the present invention includes a pipe body 1 and a centralizing strip 2. There are through holes 1-3 in the pipe body 1. The upper part of the pipe body 1 is processed with a flat body type external thread 1-1, and the bottom part of the pipe body 1 is processed with a flat body thread. Body-shaped internal thread 1-4, the flat-body-shaped external thread 1-1 is the same as the flat-body-shaped internal thread 1-4, and has the same structure size, and the external processing of the pipe body 1 is provided with a settling groove 1-2. There are 3-8 placement grooves 1-2, which are evenly distributed on the outer wall of the pipe body 1. The placement grooves 1-2 are divided into upper groove section 1-2-1, middle groove section 1-2-3 , the lower groove section 1-2-2, the middle groove section 1-2-3 is a dove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com