A hyperbolic arc long-span steel truss and its manufacturing method

A steel truss and large-span technology, which is applied in the hyperbolic arc-shaped long-span steel truss and its production field, can solve the problems that the structure cannot be handled well, the connection node processing is cumbersome, etc., so as to facilitate the organization of flow construction and ensure the accuracy of manufacturing assembly , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

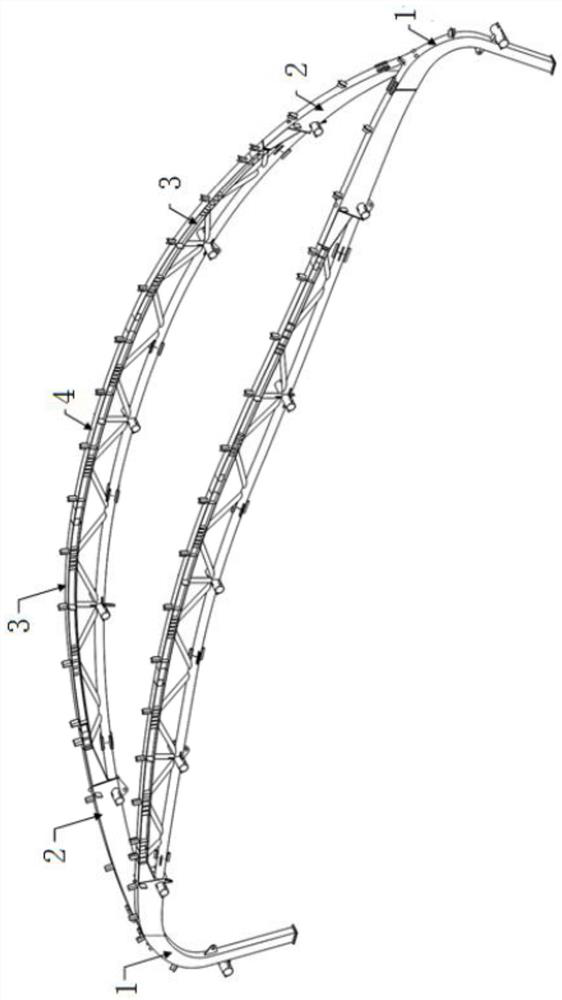

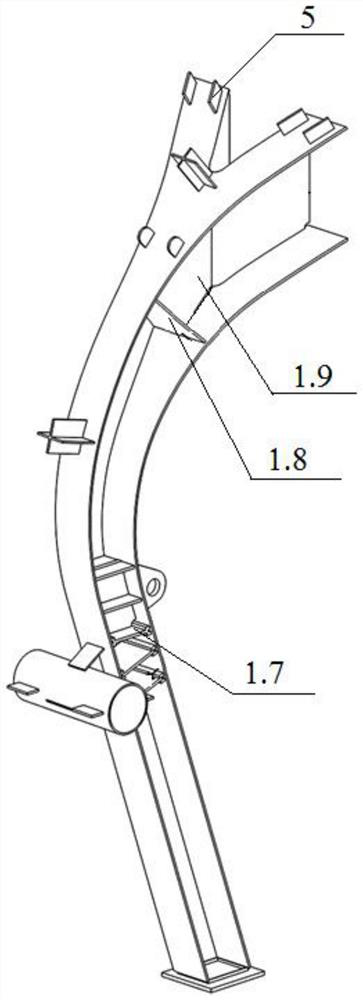

[0038] Such as figure 1 As shown, a hyperbolic arc-shaped long-span steel truss in this embodiment has several support rods arranged at the bottom of the truss, and the support rods are used to transmit force to the lower frame. The truss includes a Y-shaped column 1, a first truss, and a second truss in two floors. The vertical plane where the Y-column 1 is located in the two floors is used as a symmetrical plane. The first truss and the second truss are arranged symmetrically along the symmetrical plane. The same-side ends of the first truss and the second truss are correspondingly connected to the bifurcated ends of the Y-shaped column 1 of the landing section on the same side. Among them, the first and second trusses respectively include a single-curvature truss 4, a hyperbolic truss 3 and a transition section bending and torsion box 2, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com