MPO/MTP type optical fiber connector automatic fastening and grinding clamp

A technology of movable connectors and grinding fixtures, which is applied in the field of tooling and fixtures, can solve the problems of time-consuming and low product consistency, and achieve the effects of fast locking speed, improved unlocking efficiency, and improved locking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

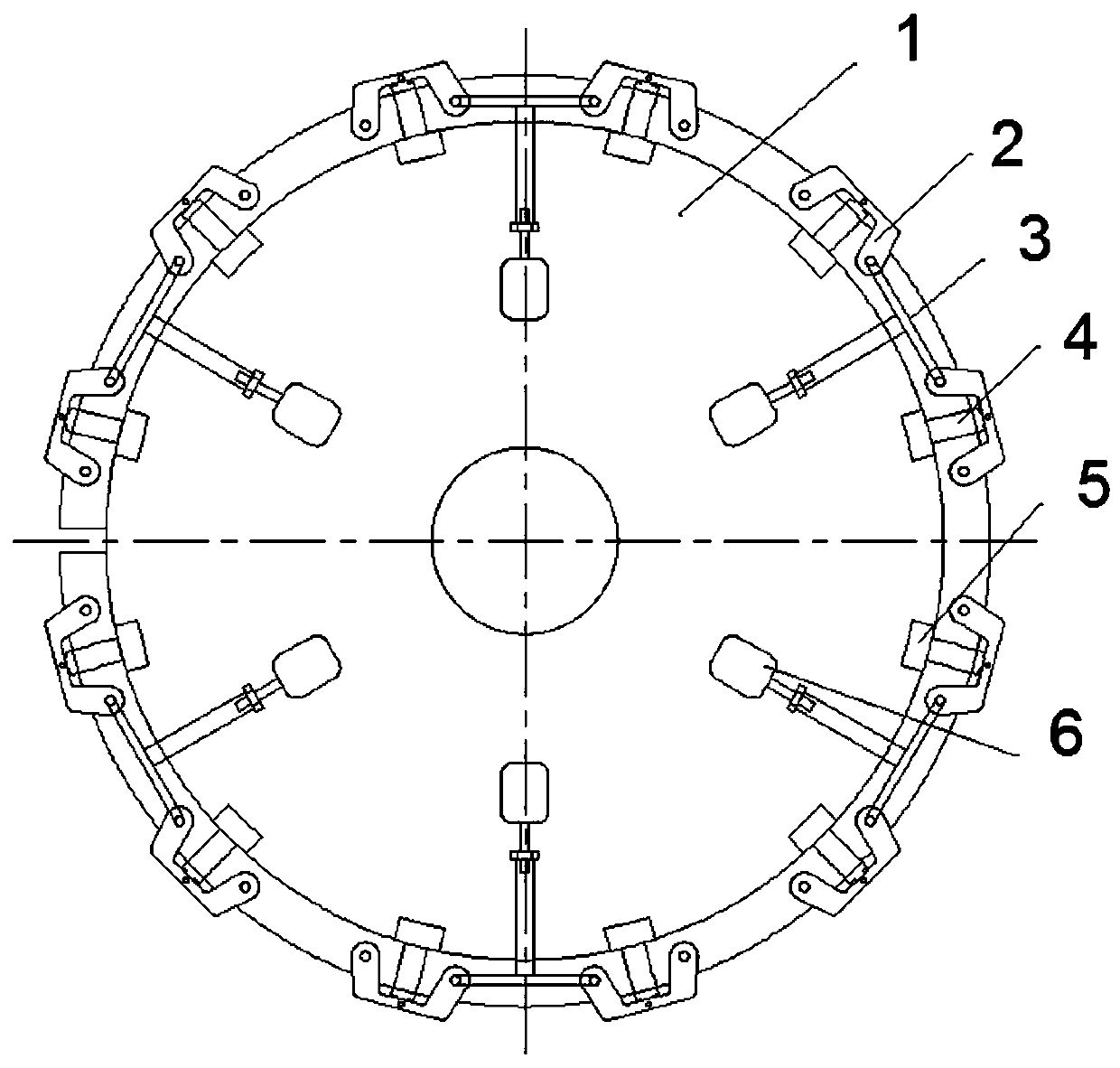

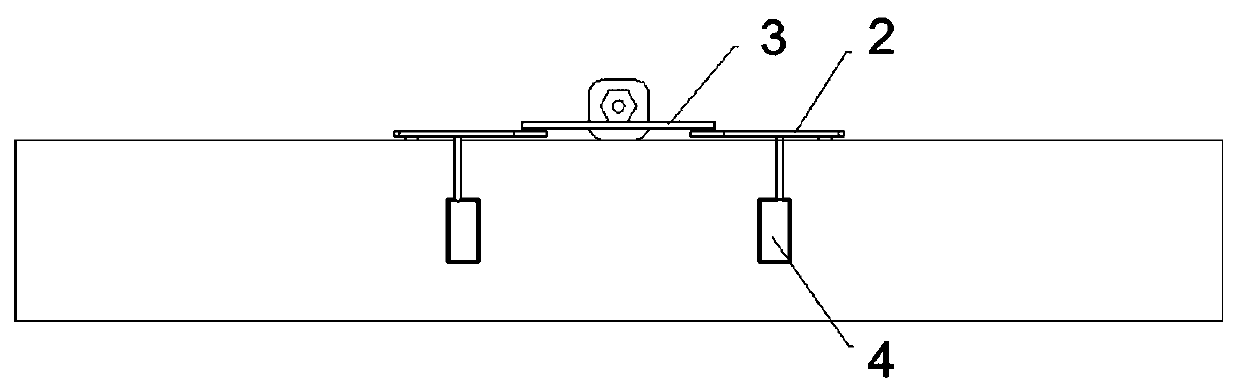

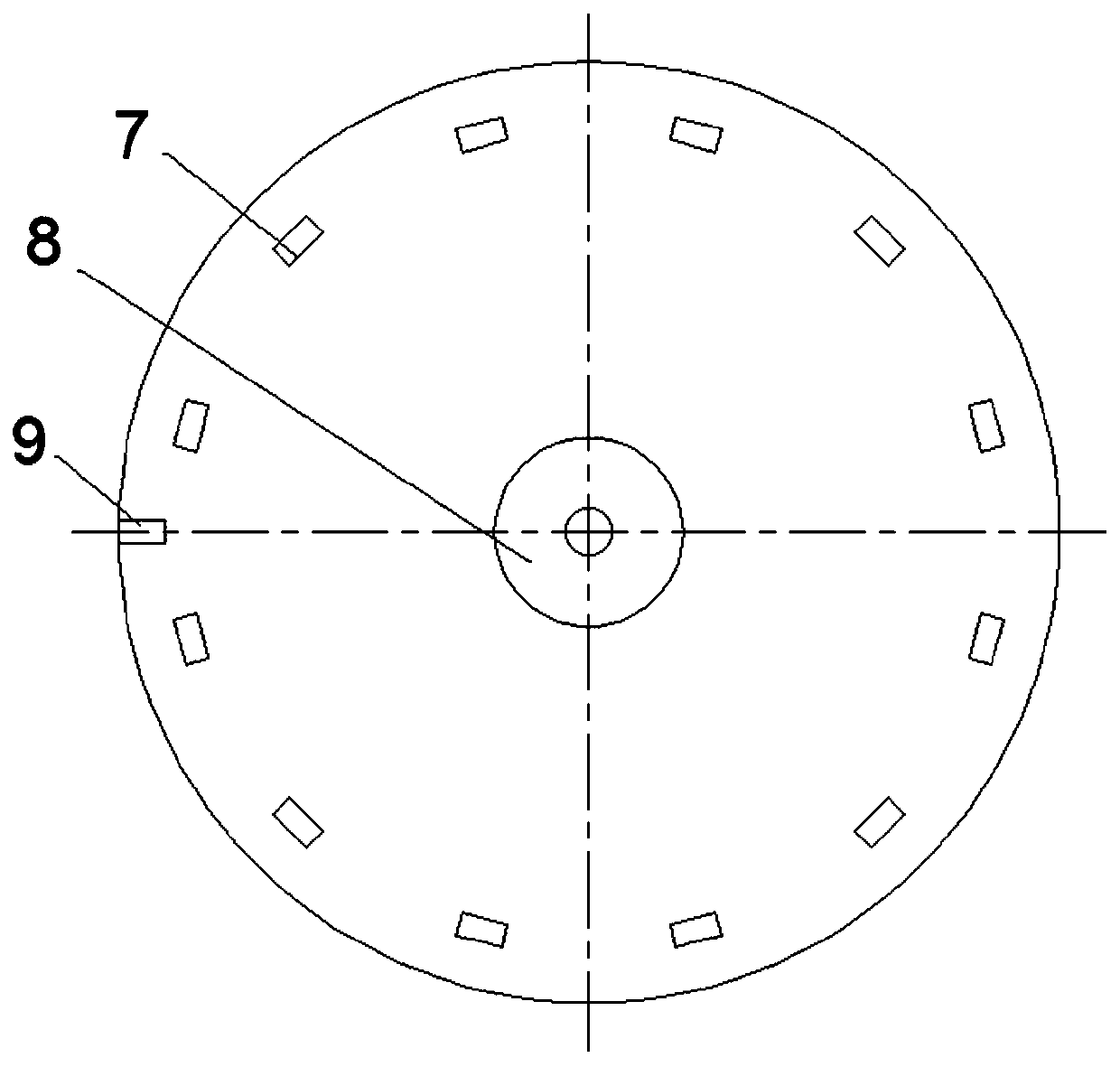

[0024] Such as figure 1 As shown, an MPO / MTP type optical fiber movable connector automatically fastens the grinding fixture, including an upper fixture and a base; the upper fixture includes a fixed plate 1 and a plurality of locking components, and the fixed plate 1 is provided with a plurality of It is used to insert the ferrule hole 5 of the optical fiber active connector. The base is provided with a plurality of sensors 7 and also includes an electric control module, which controls the locking assembly to perform locking action according to the signals detected by the sensors 7 .

[0025] The locking assembly includes a briquetting block 4, a rocker arm 2, a pull rod 3 and a micromotor 6. A side hole is provided on the side wall of the ferrule hole 5. One end of the briq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com