A hanging roller cement pipe making machine

A pipe making machine and hanging roller technology, which is applied in the field of hanging roller cement pipe making machines, can solve the problems of sagging downward, insufficient to bear the weight of the hanging roller shaft, etc., and achieve the effect of improving safety and working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

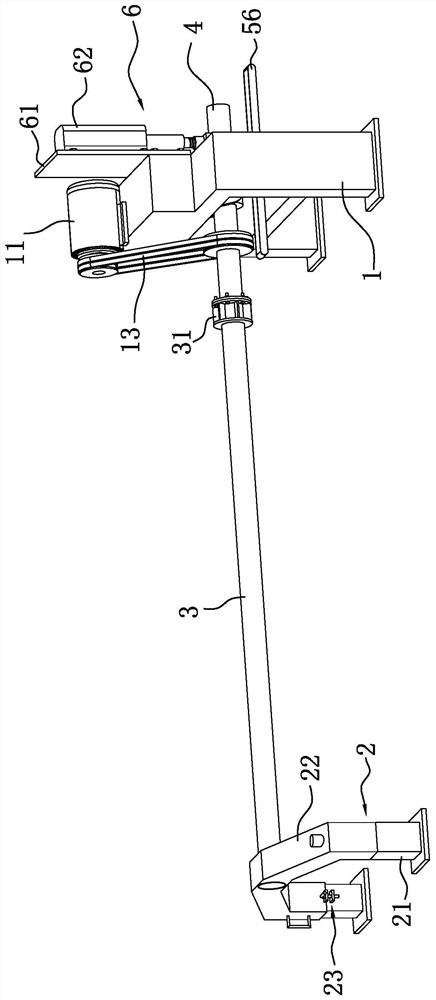

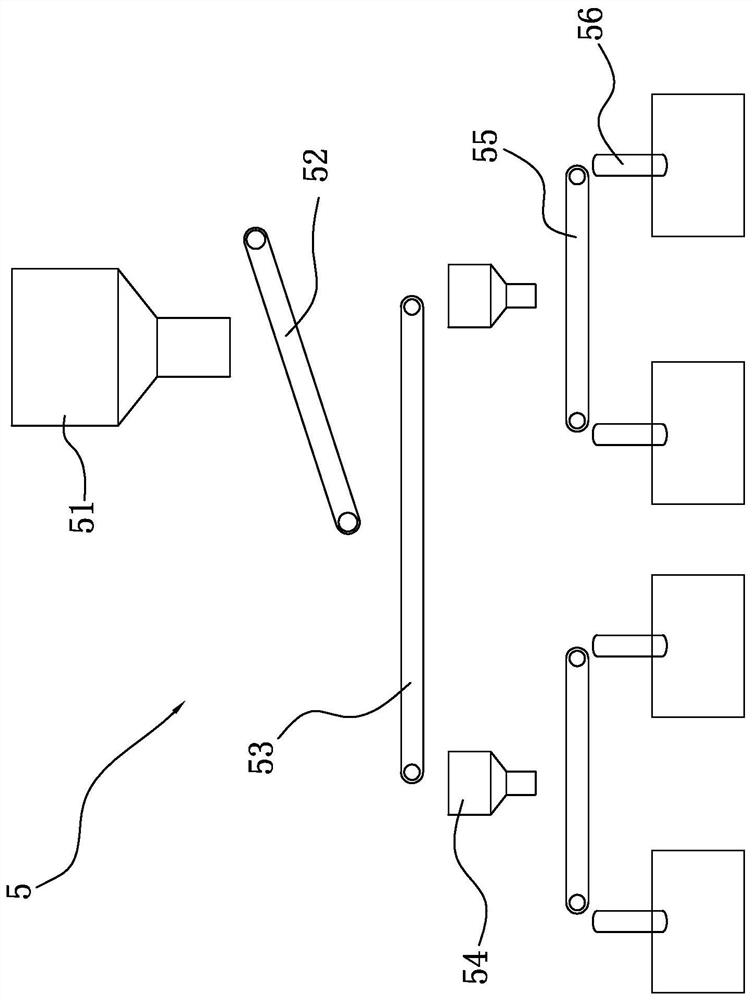

[0037] Embodiment one: a kind of suspended roller cement pipe making machine, such as figure 1 and figure 2 As shown, it includes a frame 1, a door frame 2, a suspension roller shaft 3, a driving shaft 4 and a feeding device 5. A driving motor 11 is fixedly installed above the frame 1, a shaft support seat 12 is arranged below the frame 1, and a drive shaft 4 is fixedly installed in the shaft support seat 12, and the drive shaft 4 rotates through the drive motor 11 linkage belt 13, and the suspension roller shaft 3 One end close to the frame 1 is fixed on the drive shaft 4 through a flange 31, the other end of the suspension roller shaft 3 is rotationally connected with the door frame 2, and the suspension roller shaft 3 rotates with the drive shaft 4 to work. The feeding device 5 is arranged outside the hanging roller cement pipe making machine, and the feeding device 5 can provide the concrete for pipe making for the hanging roller cement pipe making machine.

[0038] Suc...

Embodiment 2

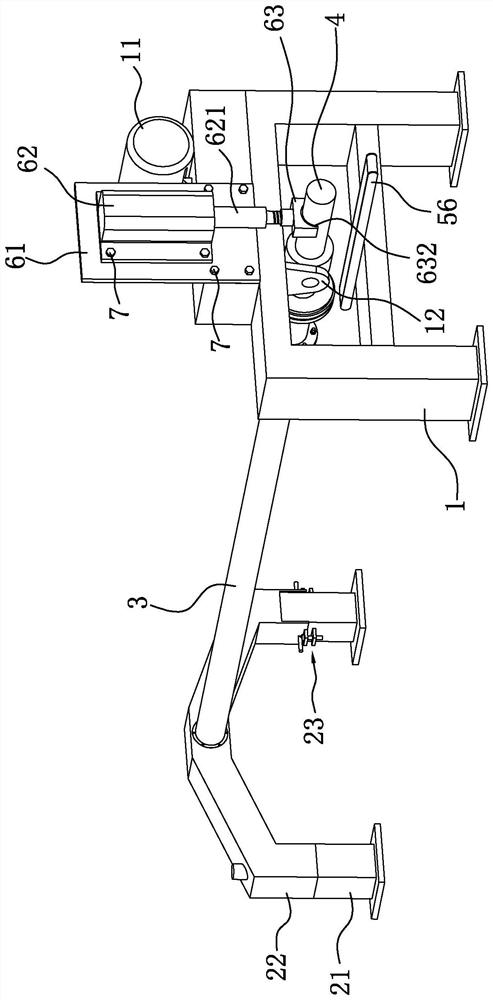

[0046] Embodiment 2: A suspension roller cement pipe making machine, the difference from Embodiment 1 is that, as Figure 7 As shown, the pressing device 6 includes a base plate 61 and a drive mechanism installed and fixed on the base plate 61. The base plate 61 is connected and installed on the frame 1 by bolts 7. The drive mechanism is a control motor 64, and the control motor 64 is connected to the base plate by bolts 7. 61, the control motor 64 is connected with a screw 65, the base plate 61 is provided with two support blocks 651, the screw 65 is rotatably connected in the two support blocks 651, the screw 65 is threadedly connected with a slide block 652, the middle position of the slide block 652 Threaded holes are provided, the two sides of the slider 652 are respectively provided with support rods 66 fixed on the bottom plate 61, and the two sides of the slider 652 are provided with through holes, the through holes on the slider 652 can accommodate the support rods 66 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com