Stationary Crane Row Level Monitoring Device

A technology for monitoring devices and cranes, which is applied in the directions of safety devices, transportation and packaging, and load hanging components. It can solve problems such as asynchronous speed of wire rope retraction, frequent crane safety accidents, and tilting of large-scale spreaders. The effect of reducing the driver's work intensity, low equipment maintenance costs, and avoiding tilt instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

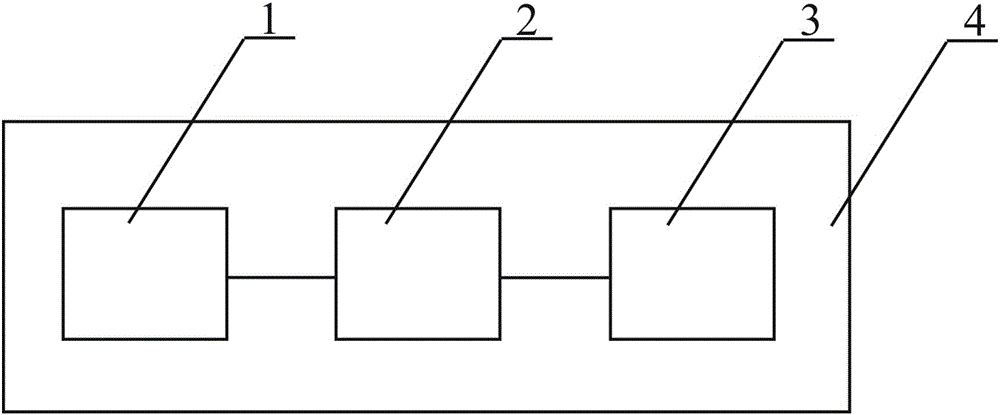

[0011] See attached figure 1 In the present invention, the horizontal control instrument 2 is connected with the crane host PLC system 1 and the angle sensor 3 to form a closed loop for controlling the level of the hoisting row of the crane. Adjustment program; the horizontal measuring and controlling instrument 2 is provided with the display of the deflection angle of the hanging row and the automatic alarm signal of the tilting of the hanging row; the horizontal measuring and controlling instrument 2 monitors the horizontal state of the hanging row through the angle sensor 3 and outputs it to the PLC system 1 of the crane host The alarm signal of the inclination of the spreader, the crane host PLC system 1 starts to automatically or manually control the horizontal state of the crane hanger according to the deflection angle of the hanger.

[0012] The present invention is installed and works like this: the crane host PLC system 1 and the level measurement and control instrume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com