Bonding protection tool and protection pasting method for rotor magnetic steel of permanent magnet motor

A technology of permanent magnet motor and magnetic steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings:

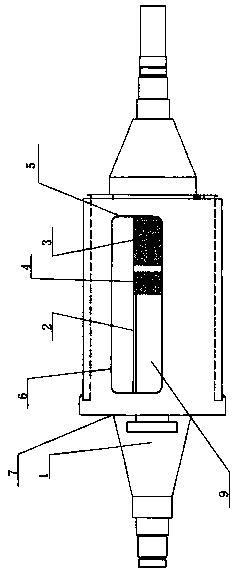

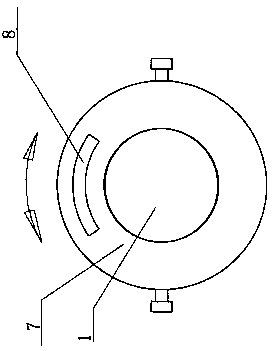

[0023] A tool for sticking and protecting permanent magnet motor rotor magnets, comprising a rotating shaft 1, a rotor core 2 is thermally sleeved on the rotating shaft 1, a sleeve 5 is movably sleeved on the rotating shaft 1, and the central axis of the sleeve 5 is connected to the rotating shaft 1 The central axes of are coincident, the sleeve 5 is rotated around the shaft 1 with the shaft 1 as the central axis, the rotor core 2 is set in the sleeve 5, and the iron core groove on the surface of the rotor core 2 and A space for magnet attachment is provided between the inner side walls of the sleeve 5, and a magnet assembly window 6 is provided on the cylindrical side of the sleeve 5 through which the magnet is attached. The outer surface of the right end of the rotor core 2 in the steel assembly window 6 is provided with a pasted magnet 3, and on the left side of the pasted magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com