Differential mechanism of automobile front drive gearbox

A differential and gearbox technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of the hidden quality of the differential and the inability to increase the number of bolts indefinitely, and achieve low cost, Cost-effective and prevent bolt breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

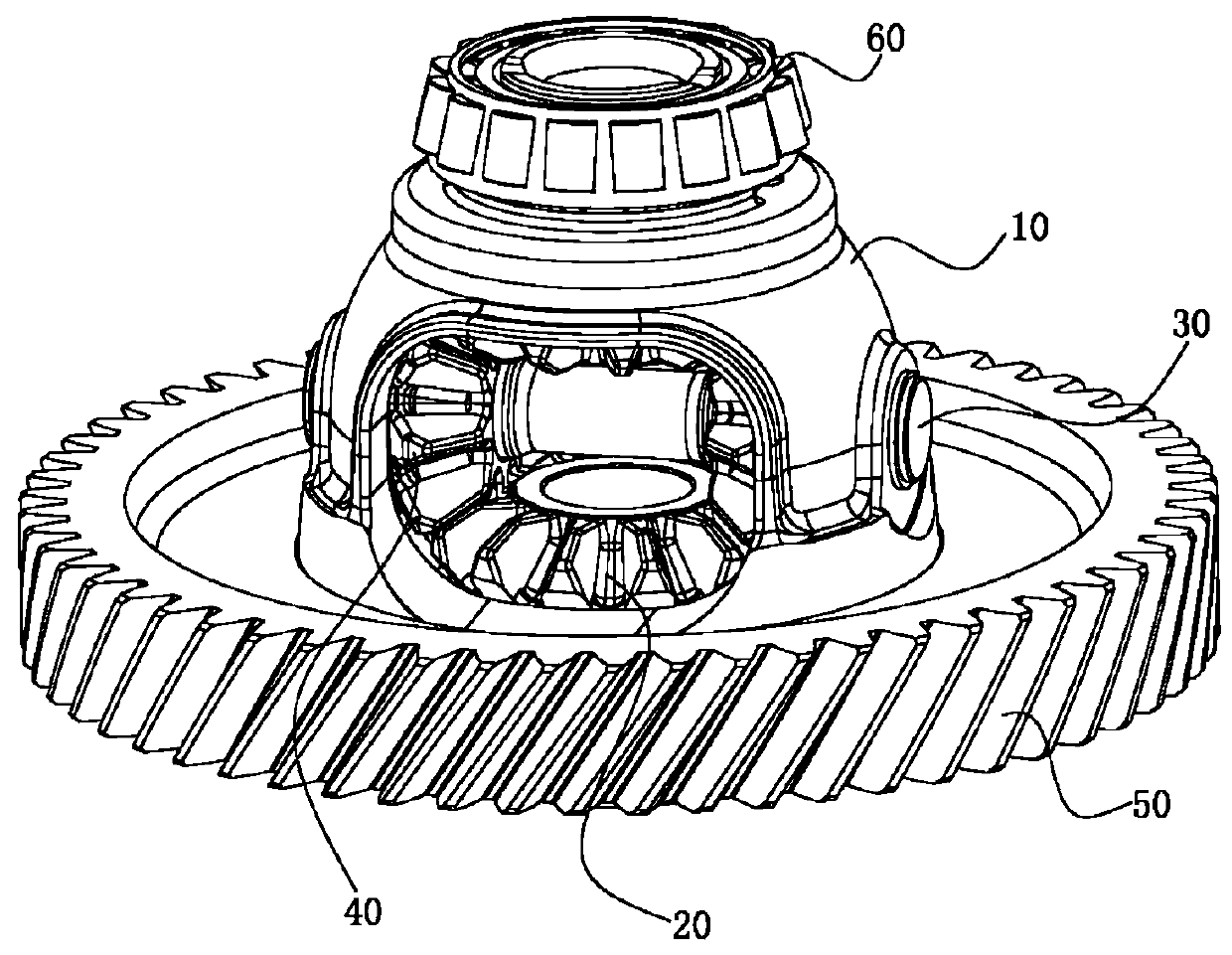

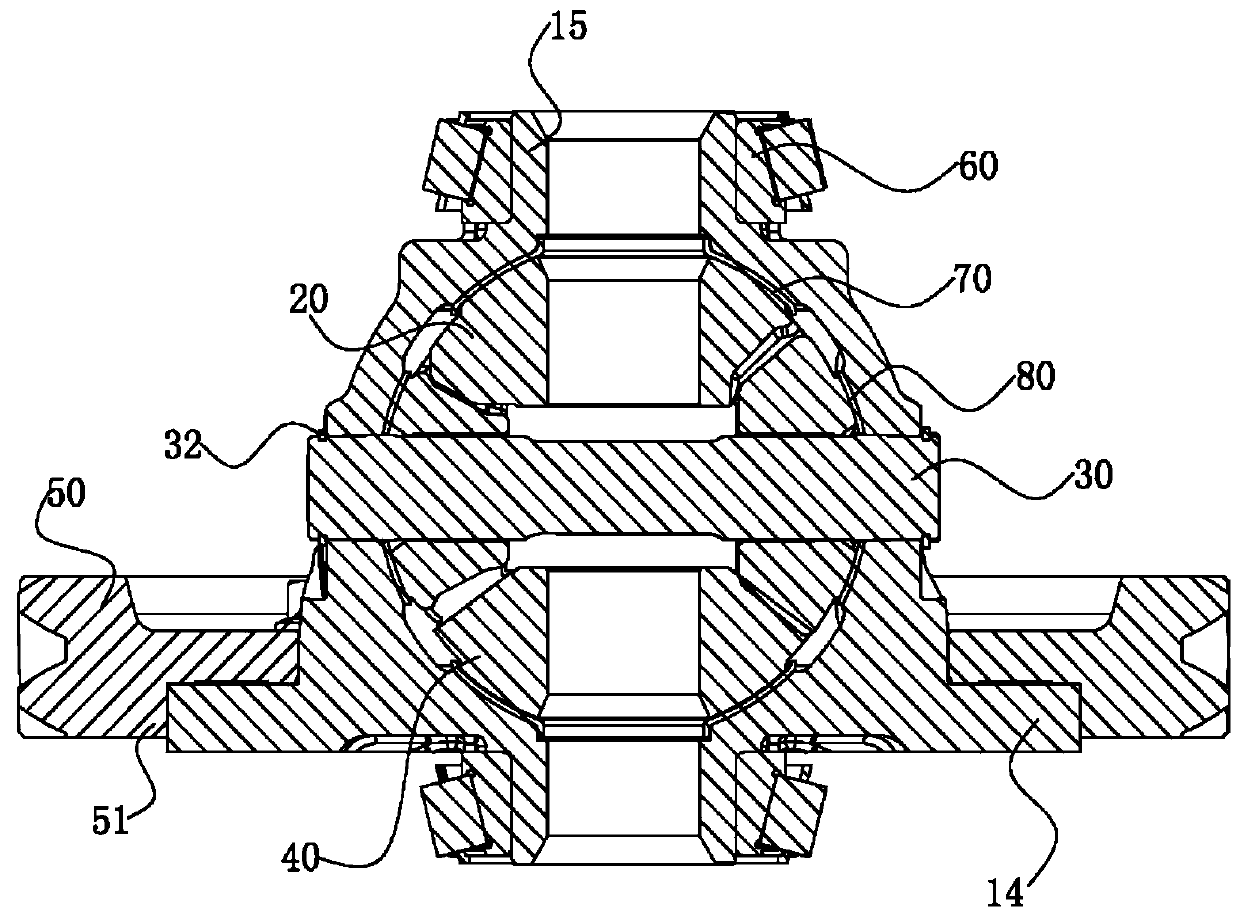

[0029] Such as figure 1 As shown, the differential of the automobile front-drive gearbox of the present invention includes a differential housing 10, a side gear 20, a side shaft (not shown in the figure), a shaft 30, a transmission gear 40, an input gear 50, and a bottom Describe each part and the relationship between them in detail:

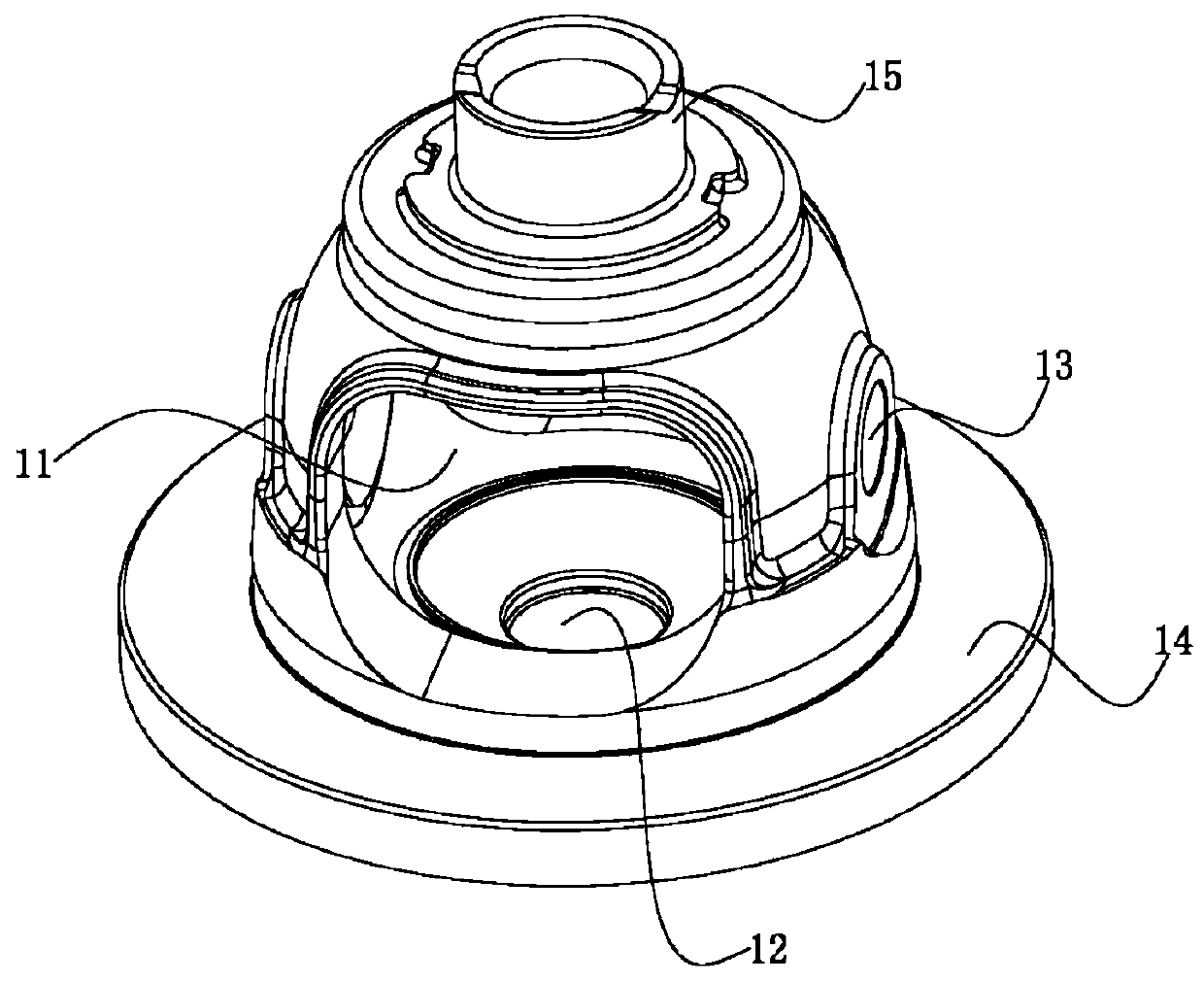

[0030] Such as Figure 1 to Figure 3 As shown, the differential case 10 has a hollow cavity 11, the cavity 11 of the differential case 10 is preferably set as a spherical cavity, the cavity 11 of the sphere can make the There is a larger mating surface between the side gear 20 and the transmission gear 40 and the differential case 10 , so that the stability of the side gear 20 and the transmission gear 40 is better. Two ends of the differential case 10 are respectively provided with a first mounting hole 12 , and a peripheral surface of the differential case 10 is provided with two opposite second mounting holes 13 . The outer shape of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com