Mortar laying device

A technology of laying sand and dry sand, which is applied in the direction of construction and building construction, which can solve the problems of low efficiency and achieve the effect of meeting the process requirements and high laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] As recorded in the background technology, in the construction industry, tiles are often laid on walls or floors for decoration. When laying tiles, manual laying is the main method. Usually, it is necessary to lay a dry mortar primer first, and then lay glue Then lay the tiles smoothly, and tap the bricks with a rubber hammer to vibrate the concrete. However, there are many problems in the manual construction process, especially when laying materials, large-scale paving, poor flatness, and low laying efficiency of dry mortar layer and rubber layer.

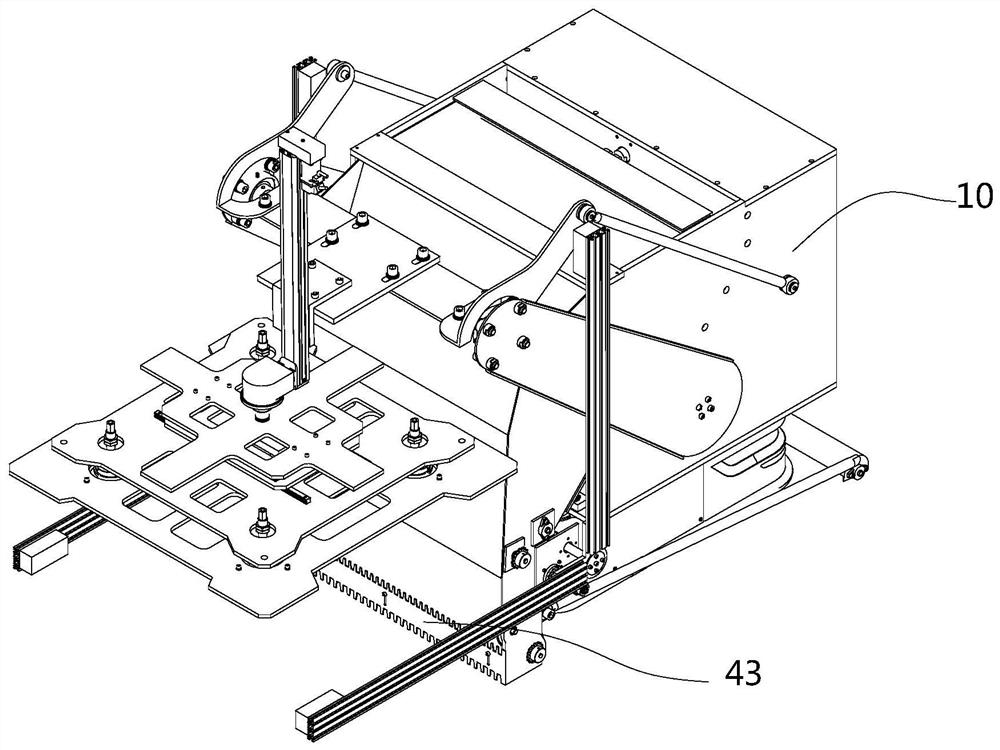

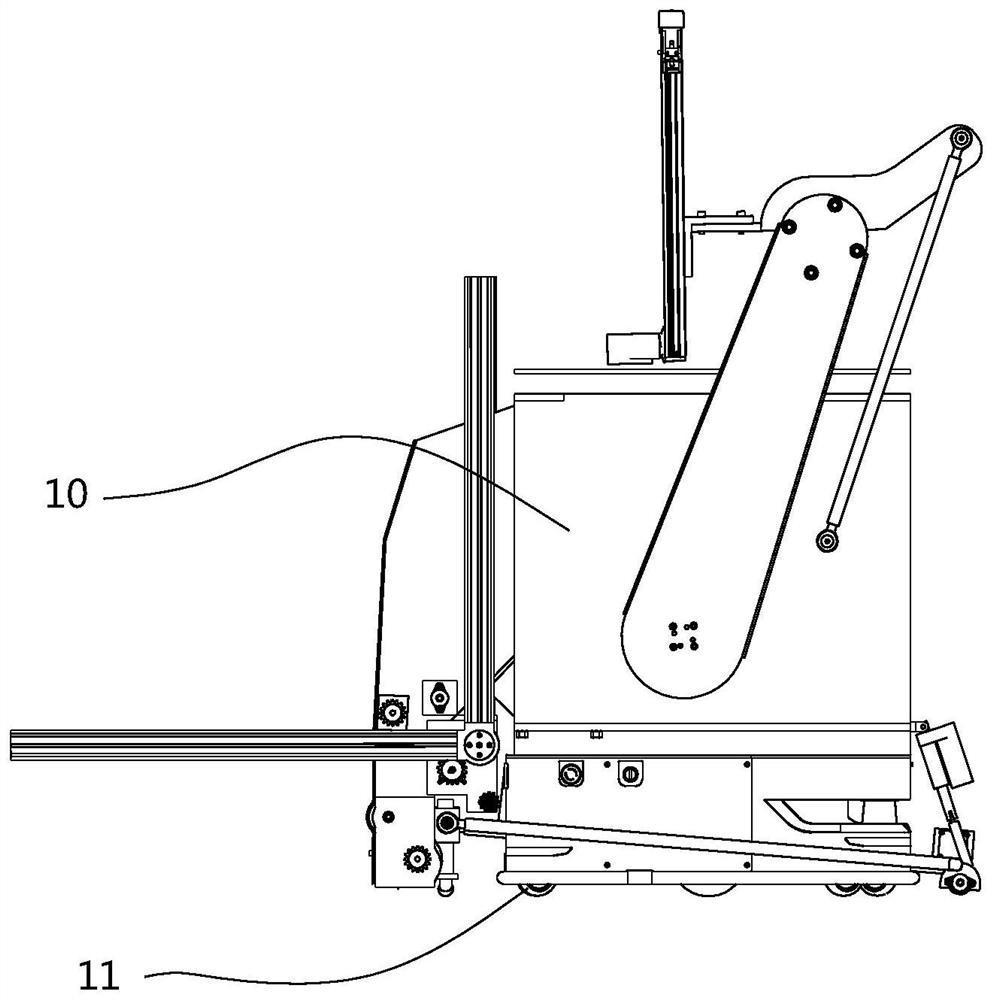

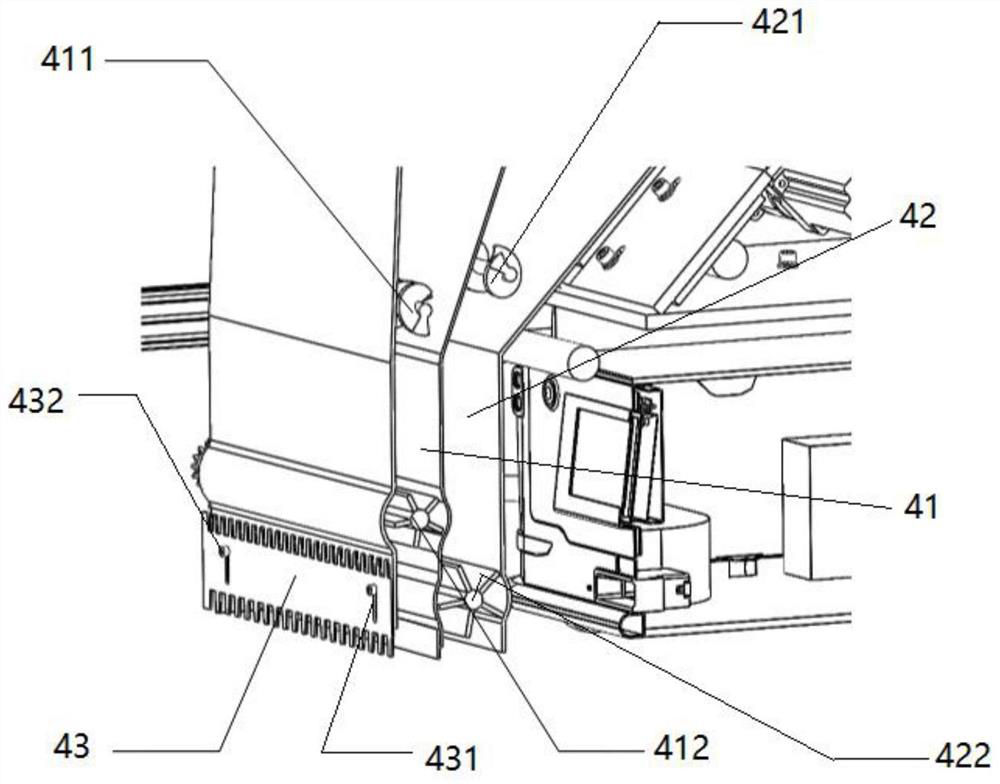

[0023] To solve the above problems, see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a mortar laying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com