Automatic loading device used for machining and preventing workpieces from gliding

An automatic feeding and mechanical processing technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of inconvenient lifting, lifting, and inconvenient workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

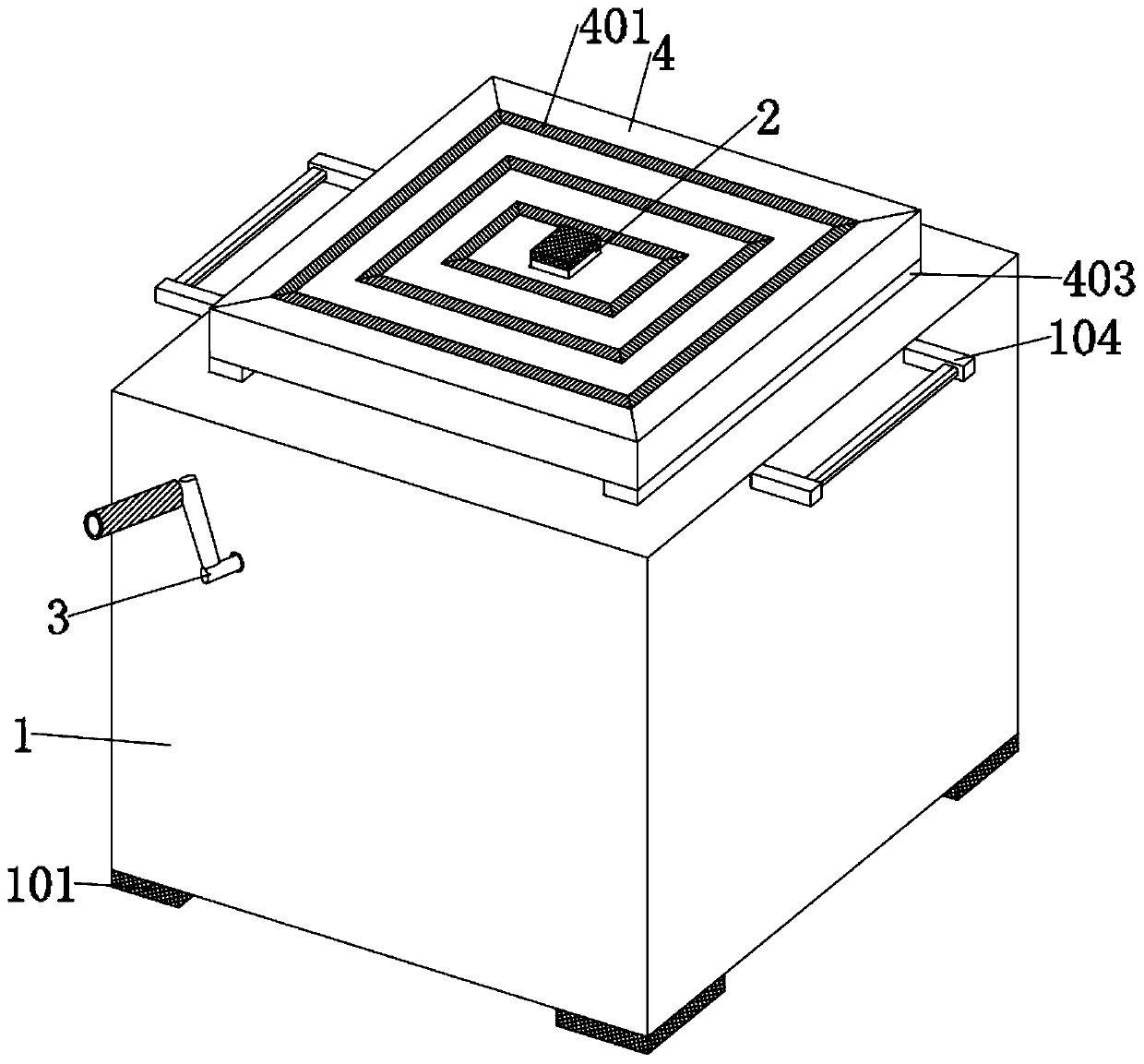

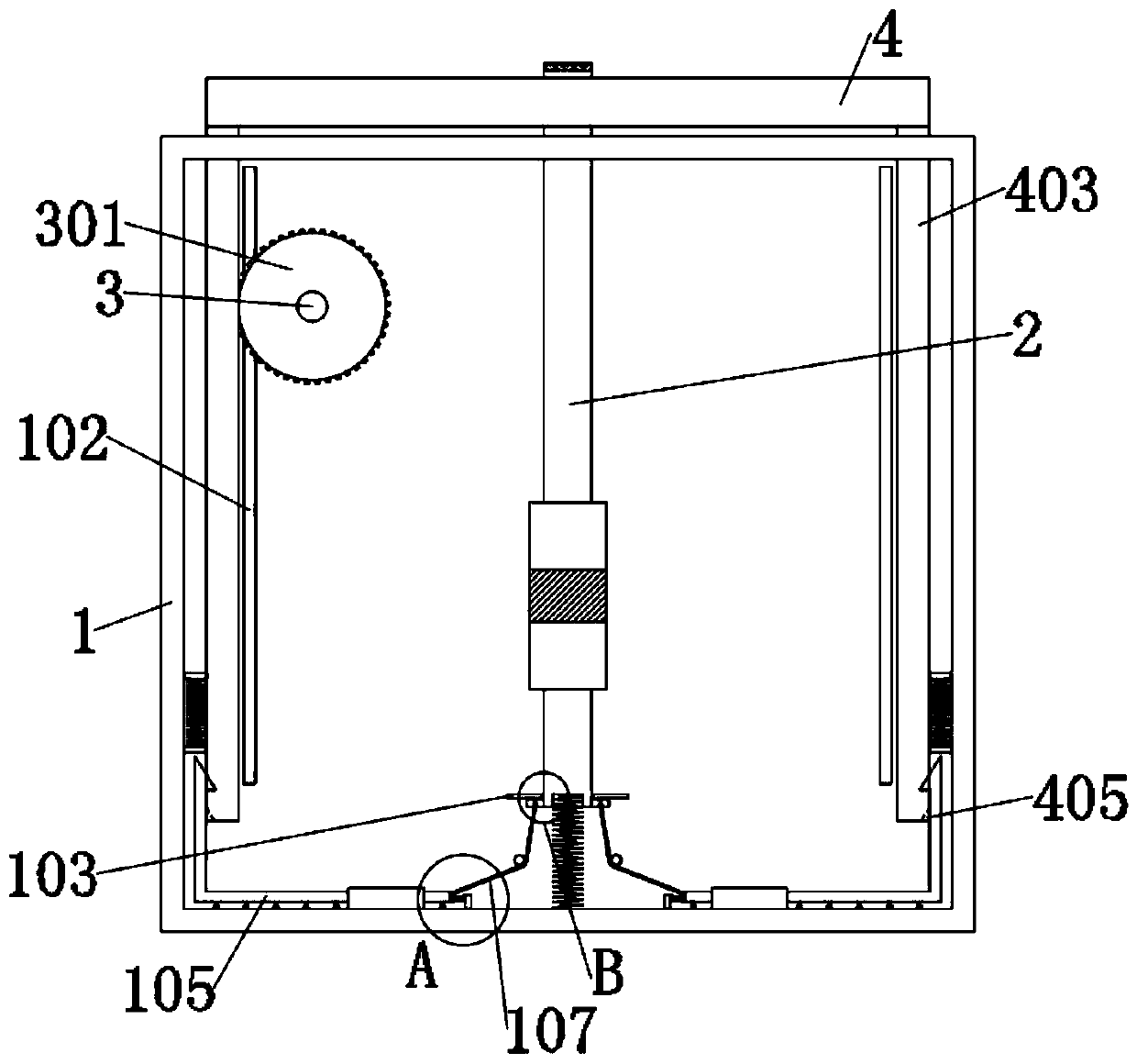

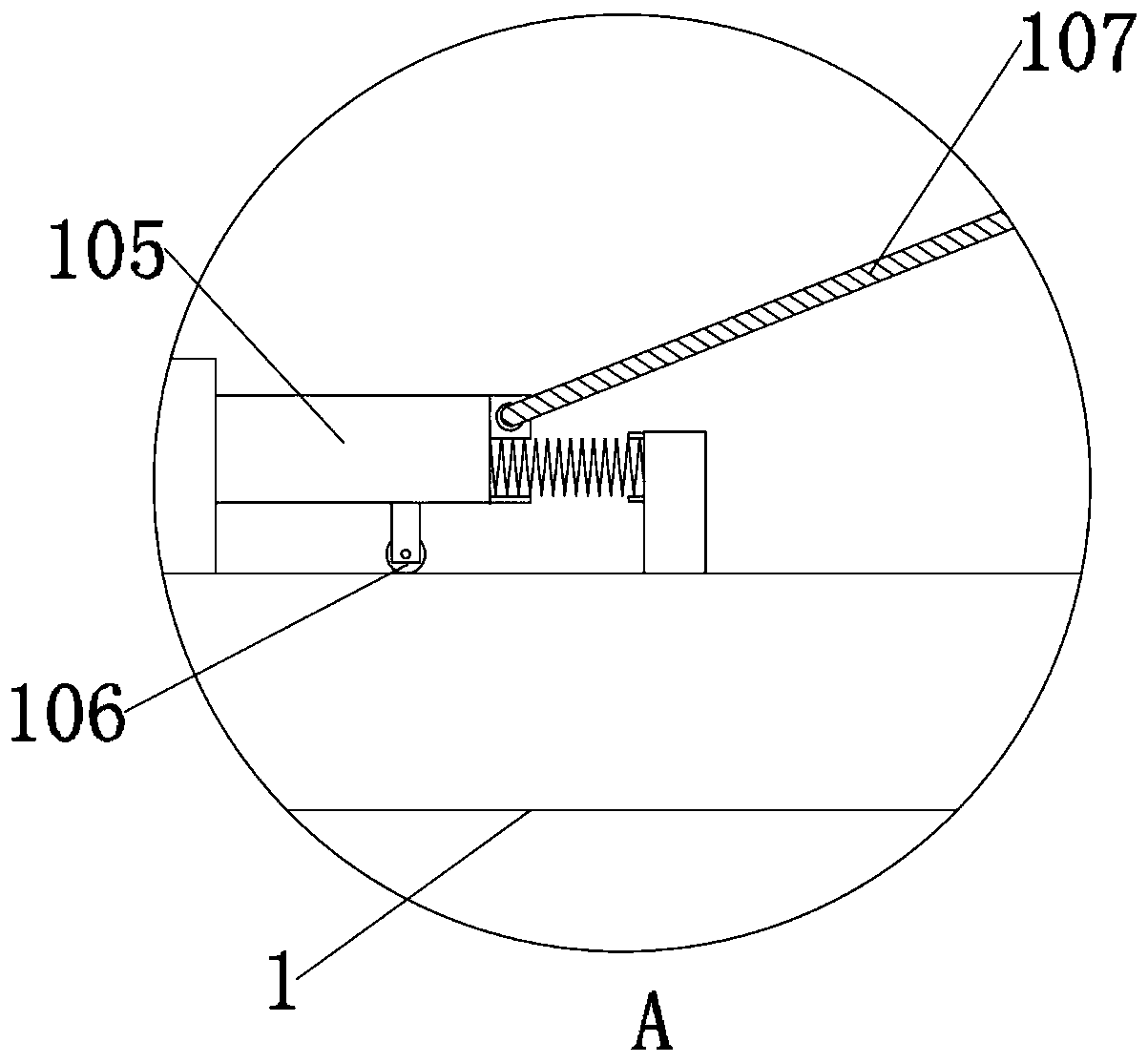

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033]The present invention provides an automatic feeding device for mechanical processing to prevent workpieces from sliding, including: a main body 1, a bottom part 101, a guide plate 102, a baffle plate 103, a mounting part 104, a moving part 105, a bottom wheel 106, and a traction rope 107 , trigger piece 2, bottom groove 201, side plate 202, shaft rod 3, gear 301, force receiving piece 302, clip piece 303, rising piece 4, anti-slip piece 401, center hole 402, side piece 403, card slot 404, guide Groove 405 and force-receiving hole 406; the main body 1 is a rectangular internal hollow structure, and the bottom part 101 is a rectangular plate-shaped structure, and the inner sides of the main body 1 are provided with a rectangular guide plate 102, and the interior of the main body 1 is provided with a baffle 103; the moving part 105 is installed on both sides of the inner bottom end of the main body 1 through a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com