Laser cutting machine hydraulic lifting working platform

A laser cutting machine, hydraulic lifting technology, applied in laser welding equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of troublesome maintenance, long installation time, high cost, and achieve simple maintenance in the later stage, improve production efficiency, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

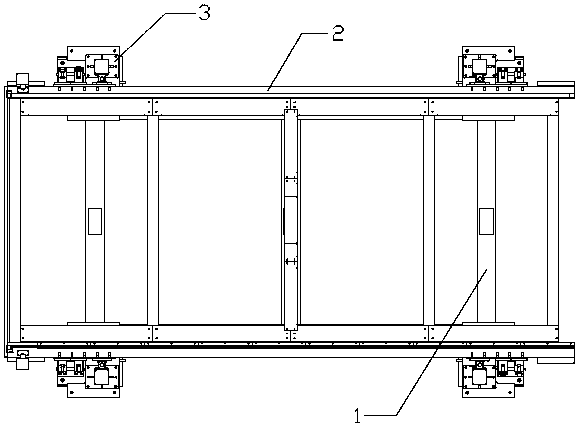

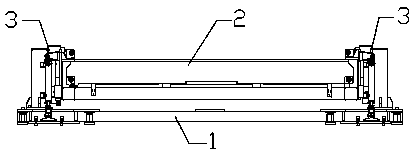

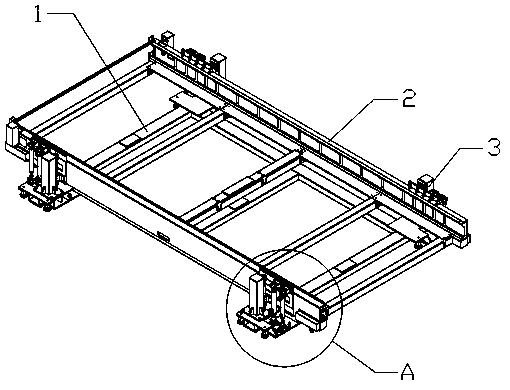

[0022] Figure 1 to Figure 3 A laser cutting machine hydraulic lifting workbench is shown, which includes a chassis 1 and a workbench 2 arranged above the chassis 1. Both the chassis 1 and the workbench 2 have a rectangular structure, and the outer sides of the chassis 1 are respectively arranged near the four corners. A base 11 extending outward, on which a hydraulic lifting device 3 capable of moving vertically up and down is arranged, the top of the hydraulic lifting device 3 is connected to the workbench 2, and four groups of hydraulic lifting devices arranged on the chassis 1 The device 3 realizes the pressure balance of the oil circuit by connecting the external synchronous hydraulic station, and drives the workbench 2 to realize vertical movement up and down.

[0023] like Figure 4 As shown, the hydraulic lifting device 3 is composed of a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com