Track vibration attenuation fastener and installing method

A vibration-damping fastener and track technology, which is applied in the field of rail transit, can solve problems such as high cost, high installation height, and increased construction difficulty, and achieve the effects of enhancing gauge maintenance ability, reducing installation height, and improving track stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

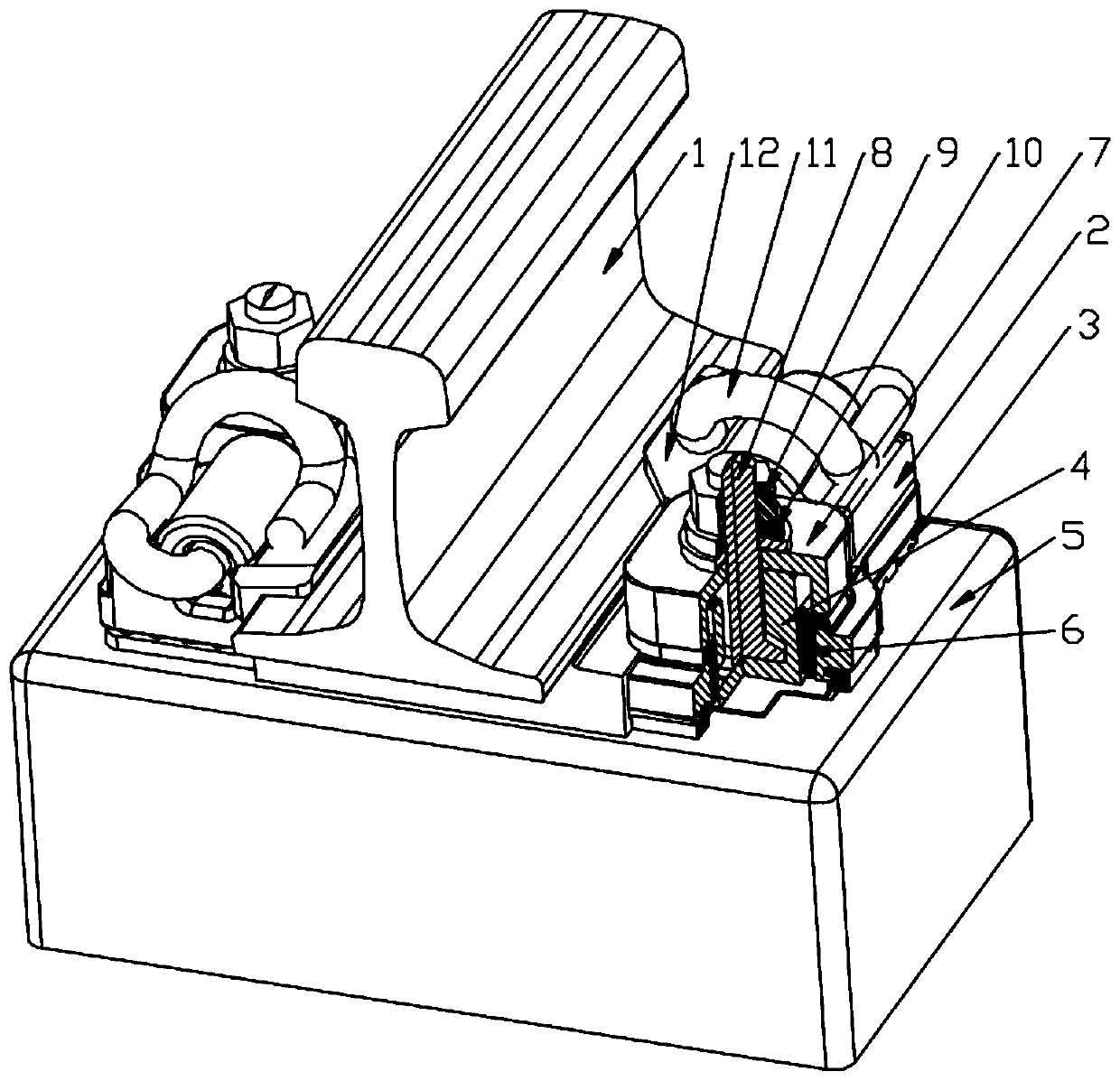

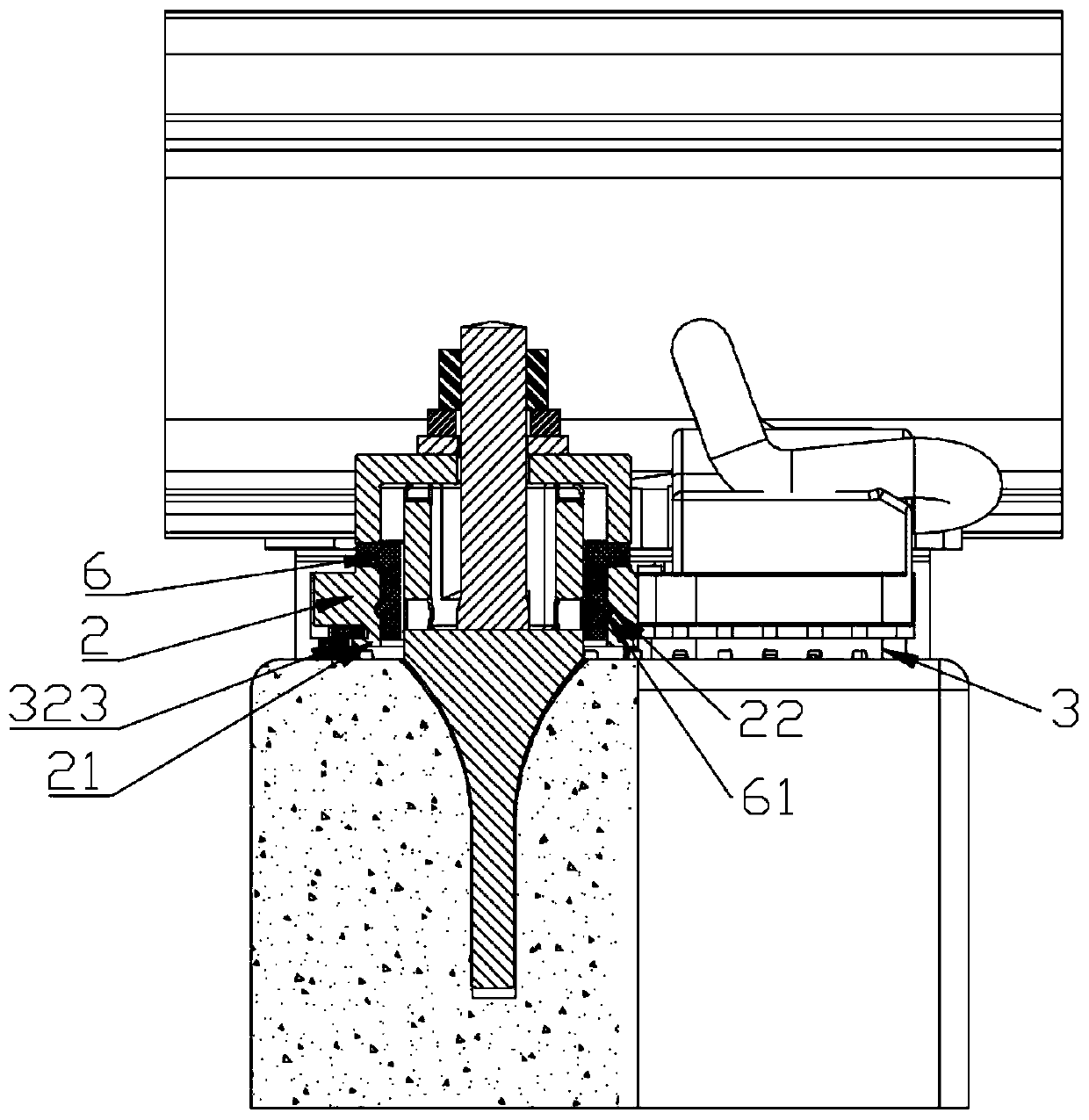

[0047] figure 1 It is the general assembly drawing of the rail damping fastener of Embodiment 1 of the present invention, such as figure 1As mentioned above, the damping fastener of the present invention includes a rail bearing plate 2, an elastic pad 3, a positioning boss 4, a concrete sleeper 5, a locking nylon sleeve 6, a locking cover plate 7, bolts 8, nuts 9, spring washers 10. Elastic bar 11 and insulating gauge block 12; wherein, the bottom of the positioning boss 4 is buried in the track foundation, and the top of the positioning boss 4 is a hollow boss structure. The rail bearing plate 2, the elastic pad 3 and the locking nylon sleeve 6 are pre-assembled structures, and the pre-assembled structure passes through the boss structure on the top of the positioning boss 4 and is arranged on the track foundation. The locking cover plate 7 is arranged on the top of the positioning boss 4 and the locking nylon sleeve 6, the bolt 8 is arranged in the hollow cavity of the posi...

Embodiment 2

[0068] What needs to be mentioned is that if Figure 6 The shown structure schematic diagram of the adhesive backing plate involved in the track damping fastener of the second embodiment of the present invention, combined with Figure 1-Figure 6 , this embodiment provides a rail damping fastener, the difference from Embodiment 1 lies in the connection mode of the elastic pad 3 and the rail support plate 2, in the second embodiment, the connection mode of the elastic pad 3 and the rail support plate 2 is Vulcanization and bonding to form a bonding backing plate 13, the bonding backing plate 13 includes an under-rail pad 131 and an under-board pad 132, wherein the under-rail pad 131 is arranged on the top of the rail support plate 2, and the under-board pad 132 is arranged on the rail support plate 2 bottom.

[0069] In the second embodiment of the present invention, the method of bonding the elastic pad 3 and the rail support plate 2 to form a bonded backing plate 13, combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com