A kind of steel wire rod for 14.9 grade high-strength fasteners and its preparation method

A high-strength, steel wire rod technology, applied in the field of steel wire rods for 14.9 high-strength fasteners and its preparation, can solve problems that do not involve delayed fracture performance of bolts, achieve enhanced hydrogen traps, and facilitate mass production , Good resistance to delayed fracture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The chemical composition of steel wire rod contains C: 0.47%, Si: 0.12%, Mn: 0.65%, P: 0.008%, S: 0.002%, Cr: 1.32%, Mo: 0.72%, Nb: 0.035%, V: 0.3%, Ti: 0.04%, Ni: 0.08%, Cu: 0.15%, Alt: 0.035%, N: 0.0085%, H: 0.00010%, O: 0.0012%, the balance is Fe and Impurities. The specific preparation process scheme is shown in Table 1.

[0027] The preparation process scheme of table 1 embodiment 1

[0028]

[0029] Table 2 shows the test results of the technical indicators of the finished steel wire rod prepared by the above preparation scheme.

[0030] The steel wire rod technical index detection result of table 2 embodiment 1

[0031]

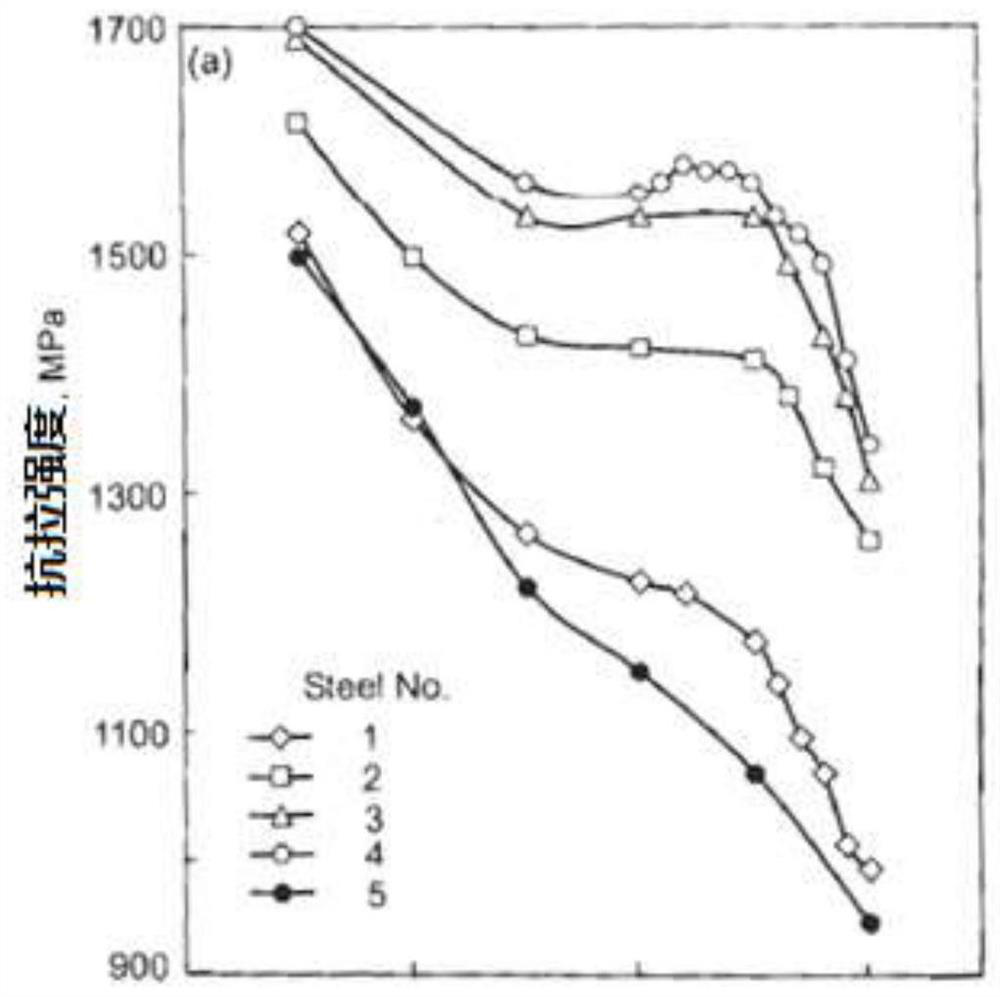

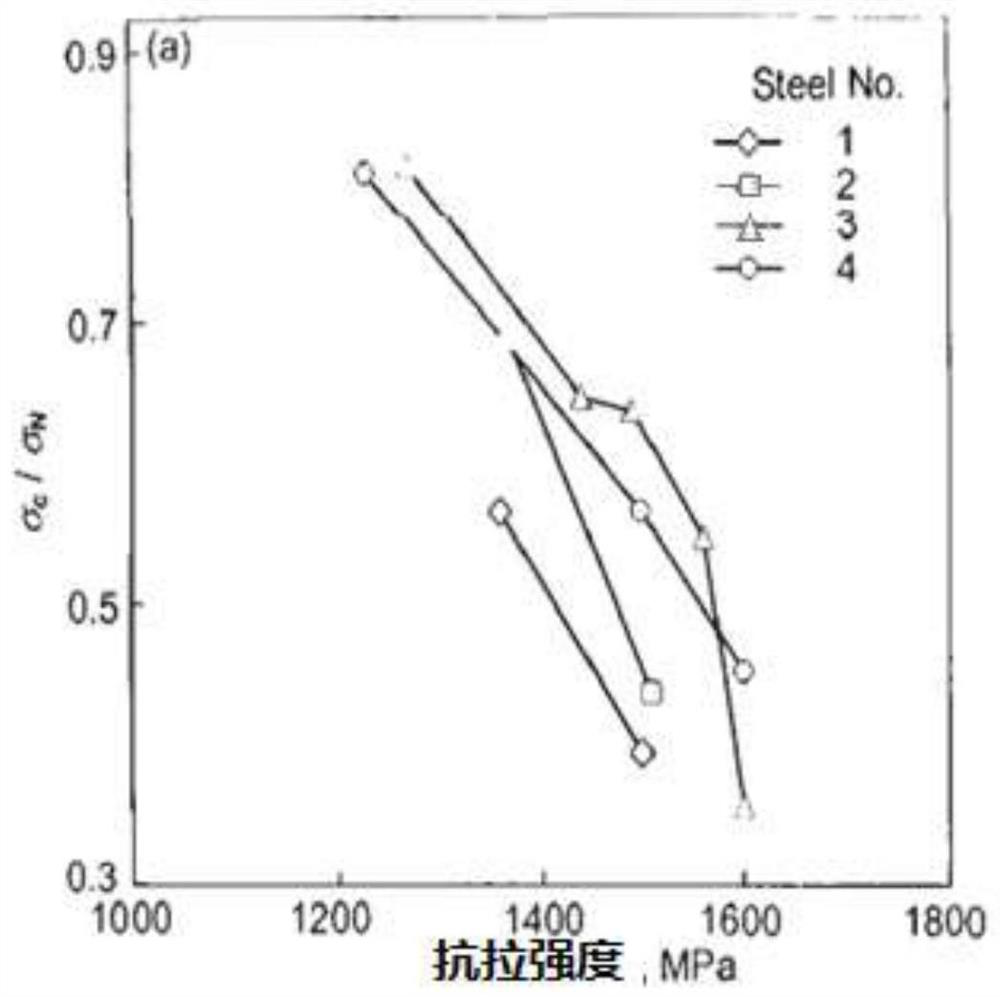

[0032] This embodiment also provides a group of experimental materials to verify the changes in Mo content and V, Nb, Ti content, and the performance difference of the steel wire rod. The chemical composition of the specific experimental materials is shown in the table below. Except for the above-mentioned decisive elemen...

Embodiment 2

[0038] Embodiment 2: the chemical composition of steel wire rod contains C: 0.46%, Si: 0.14%, Mn: 0.68%, P: 0.008%, S: 0.003%, Cr: 1.25%, Mo: 0.65%, Nb: 0.041%, V: 0.32%, Ti: 0.046%, Ni: 0.06%, Cu: 0.13%, Alt: 0.032%, N: 0.0087%, H: 0.00011%, O: 0.0014%, and the balance is Fe and Impurities. The specific preparation process scheme is shown in Table 4.

[0039] The preparation process scheme of table 4 embodiment 2

[0040]

[0041]

[0042] Table 5 shows the test results of the technical indicators of the finished steel wire rod prepared by the above preparation scheme.

[0043] The steel wire rod technical index detection result of table 5 embodiment 2

[0044]

Embodiment 3

[0045] Embodiment 3: the chemical composition of steel wire rod contains C: 0.44%, Si: 0.2%, Mn: 0.80%, P: 0.015%, S: 0.010%, Cr: 1.0%, Mo: 0.60%, Nb: 0.03%, V: 0.50%, Ti: 0.06%, Ni: 0.2%, Alt: 0.05%, N: 0.016%, H: 0.00015%, and the balance is Fe and impurities. The specific preparation process scheme is shown in Table 6.

[0046] The preparation process scheme of table 6 embodiment 3

[0047]

[0048]

[0049] The test results of the technical indicators of the finished steel wire rod prepared by the above preparation scheme are shown in Table 7.

[0050] The steel wire rod technical index detection result of table 7 embodiment 3

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com