An Improved Rotary Distribution Mechanism Based on Machining Device

A technology of material distributing mechanism and part seat, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc. It can solve the problems of unreasonable fixed structure of the feeding pipe, material falling into the ground, lack of material receiving mechanism, etc., and achieve improvement The rationality of the device structure and the effect of improving the functional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

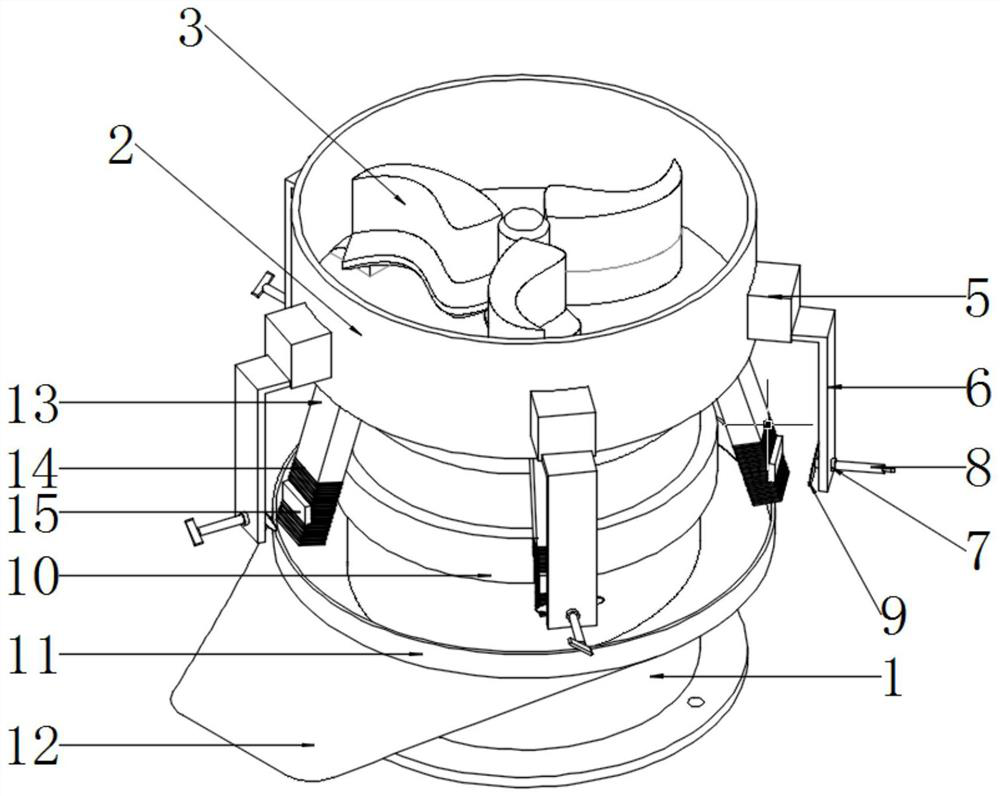

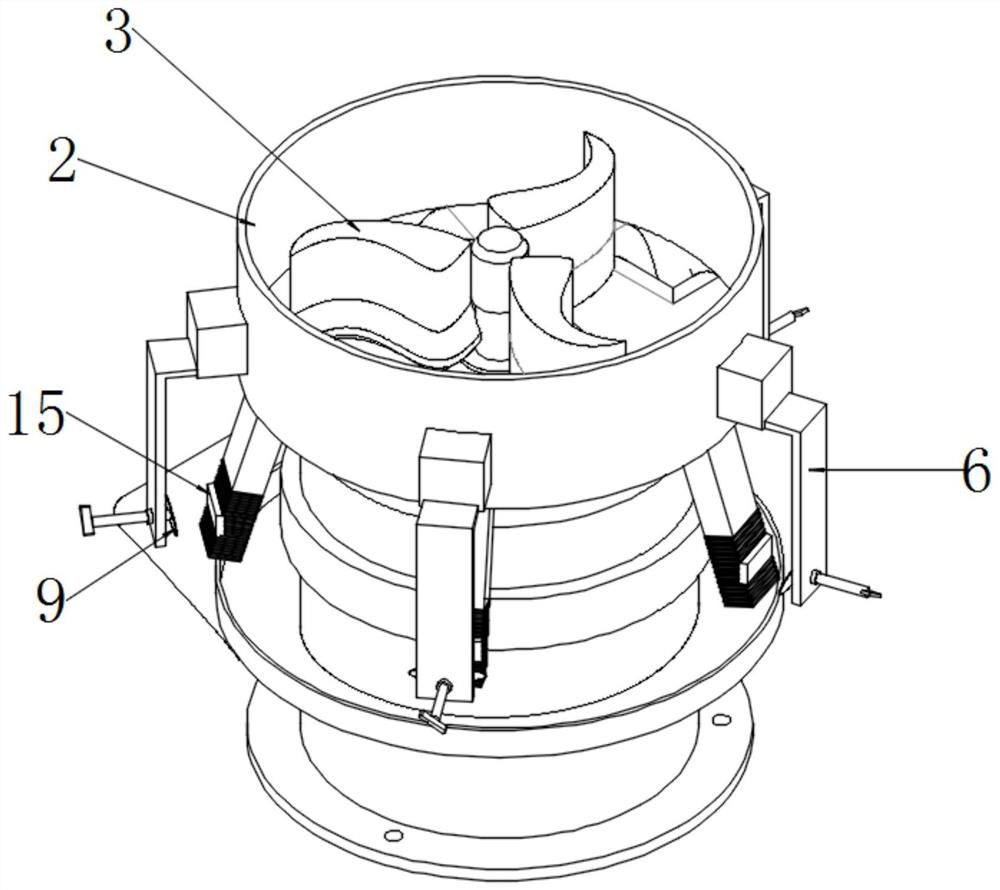

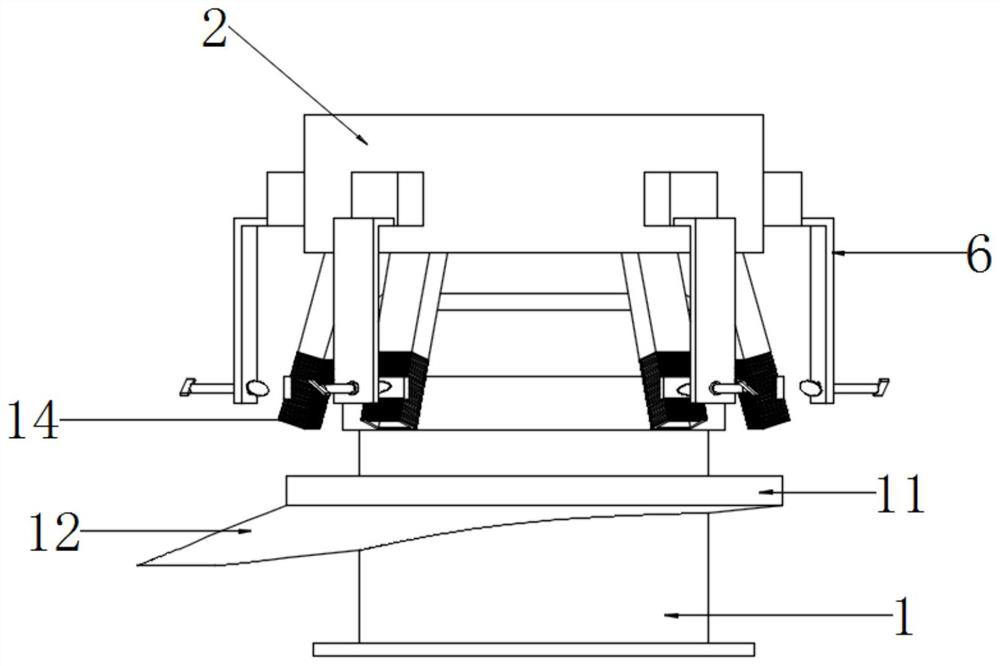

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides an improved rotary material distribution mechanism based on a machining device, which includes a base 1, a distribution cabin 2, a distribution seat 3, a discharge port 4, a connecting seat 5, a turning plate 6, a threaded sleeve 7, and a push rod 8. Pressing plate 9, functional ring 10, connecting tank 11, orifice 12, feeding pipe 13, swing section 14 and pressure seat 15; the base 1 is a cylindrical cavity structure with a motor inside, and its top is seated There is a distributing cabin 2; the distributing cabin 2 is provided with three parts seats 3 which are fixedly connected to the motor shaft for rotating and agitating action, and a circle of square solid block structures is uniformly welded on the circular cavity wall of the distributing cabin 2 Connection seat 5; the bottom surface of the connection seat 5 is also welded with a turning plate 6 of L-shaped bent plate structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com