Feed trough and feeding device

A feeding device and feeding technology, applied in the field of feeding grooves, can solve problems such as large engineering complexity, and achieve the effects of long maintenance life and good elastic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

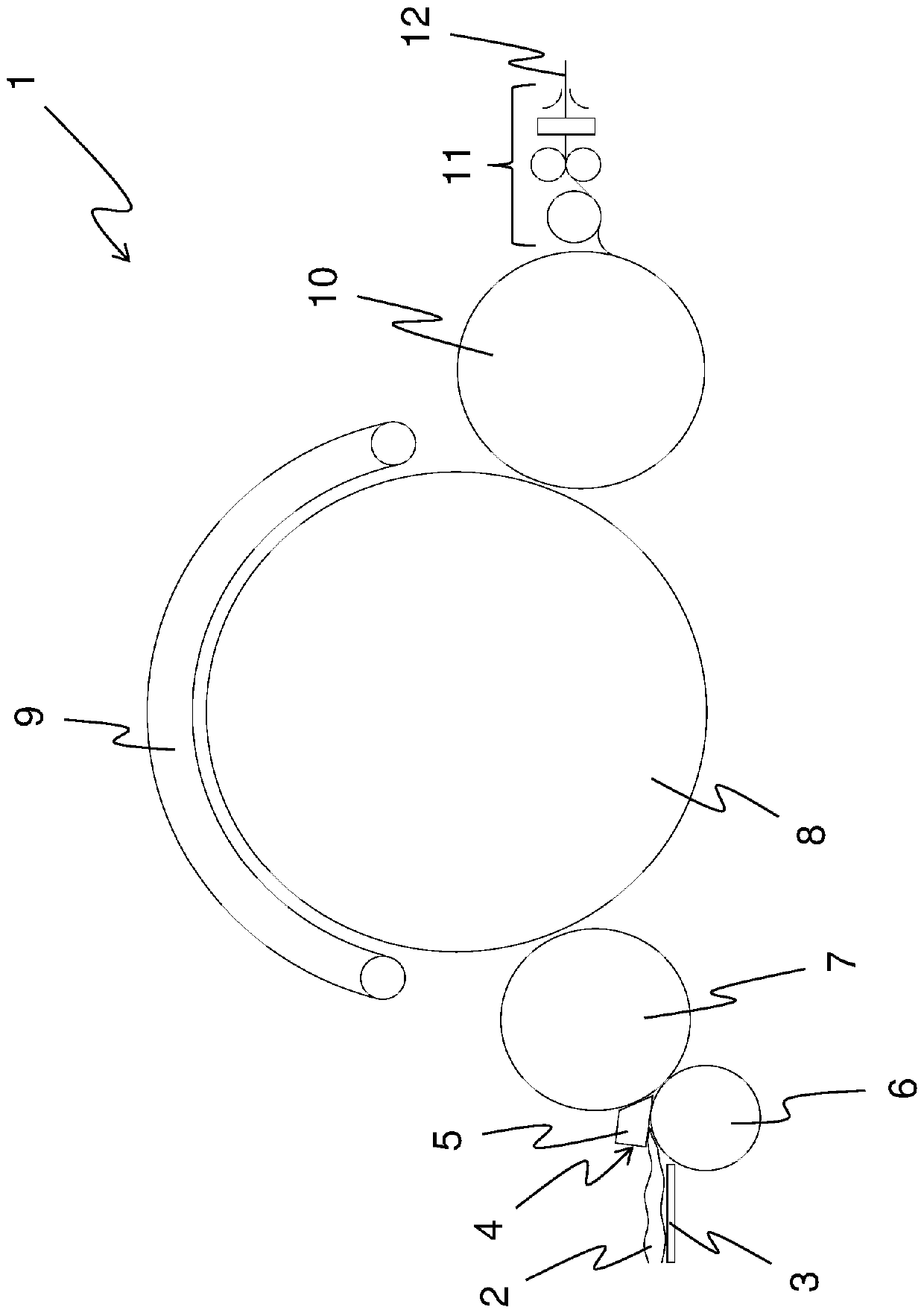

[0028] figure 1 A schematic side view of the card 1 is shown. The fibers are conveyed in the card 1 from left to right. The fiber mat 2 is first conveyed on the feed plate 3 and then enters the feed device 4 . The feed device 4 has a feed trough 5 which cooperates with a feed roller 6 . The fiber mat 2 gripped between the feed trough 5 and the feed roller 6 is then fed to the feed roller 7 .

[0029] From the feed roller 7 the nonwoven fiber proceeds to the cylinder 8 and is further processed between the cylinder 8 and a cover plate 9 which is here shown very schematically. The nonwoven fibers are then removed from the stripping roller 10 and conveyed to a compacting unit 11 where they are compacted into a sliver 12 .

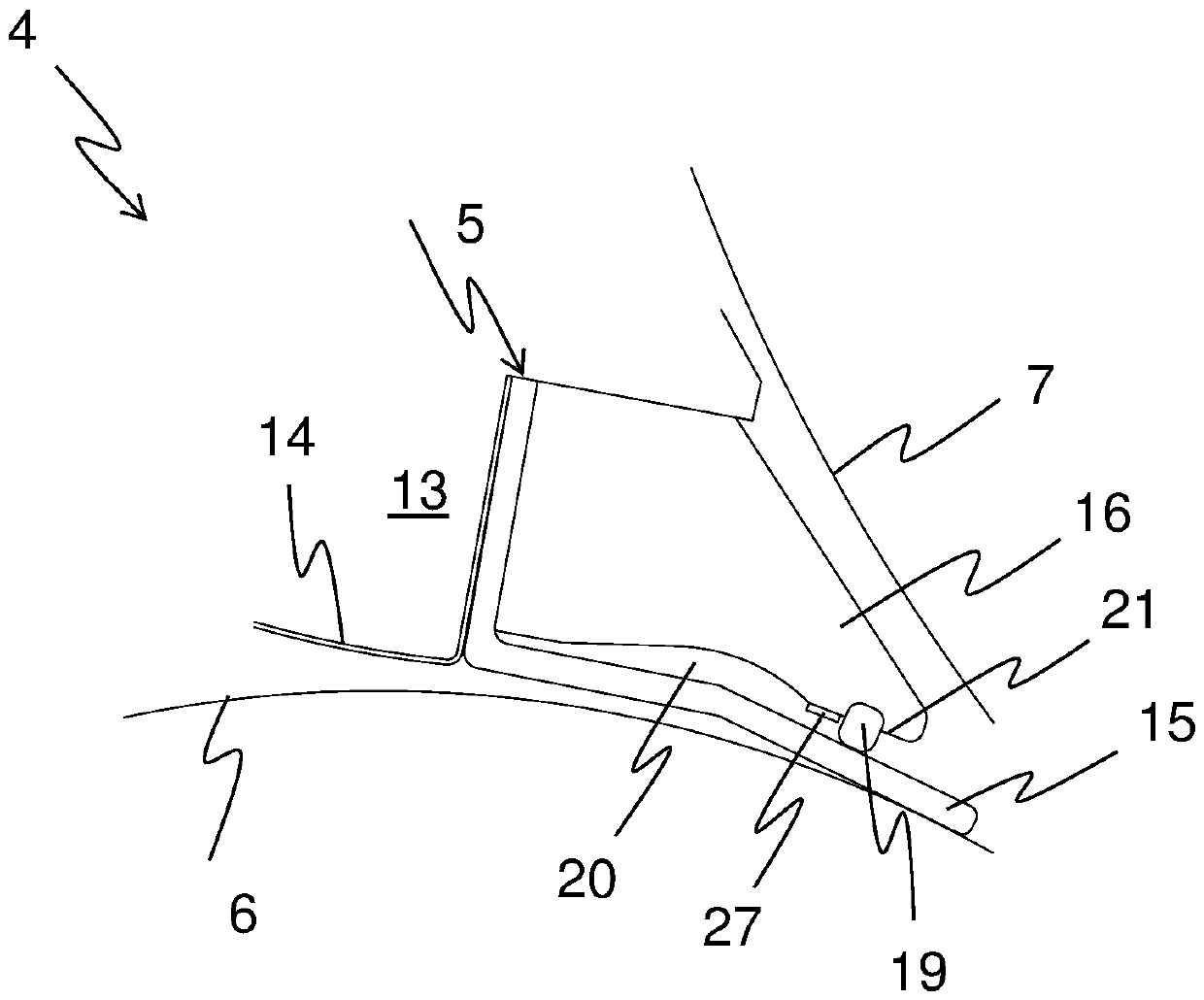

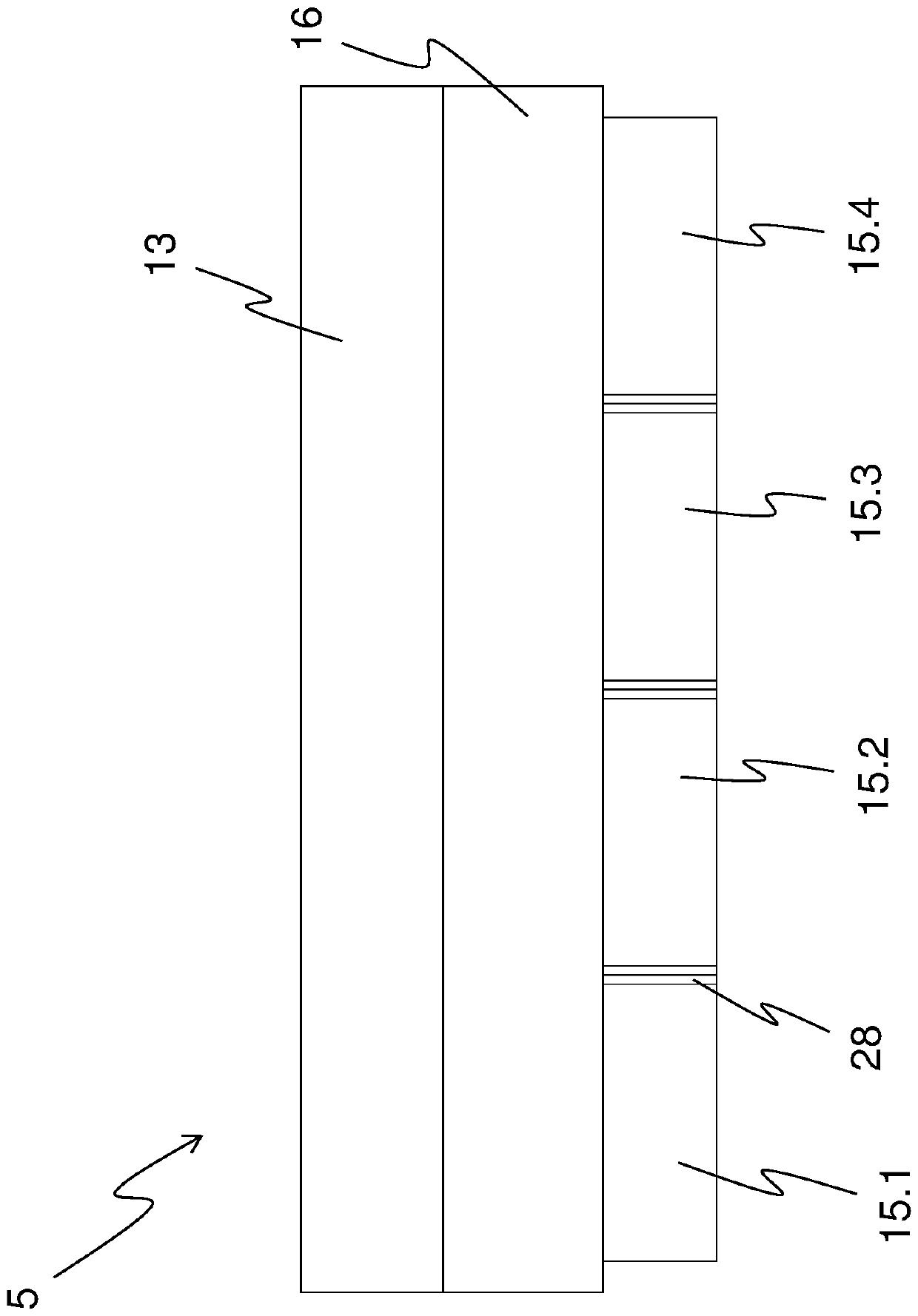

[0030] figure 2 A schematic side view of a feed device 4 according to the invention is shown. The feeding device 4 can be such as figure 1 Shown is part of a card 1 , but it could also be part of a card or cleaner. The feed device 4 has a feed trough 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com