Embedded integral hydraulic oil tank and fire truck

A hydraulic oil tank, integrated technology, applied in the direction of oil supply oil tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve problems such as difficulty in oil absorption, reduction of frame strength, and impact on service life, and achieve improvement The effect of space utilization, reduction of manufacturing difficulty and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

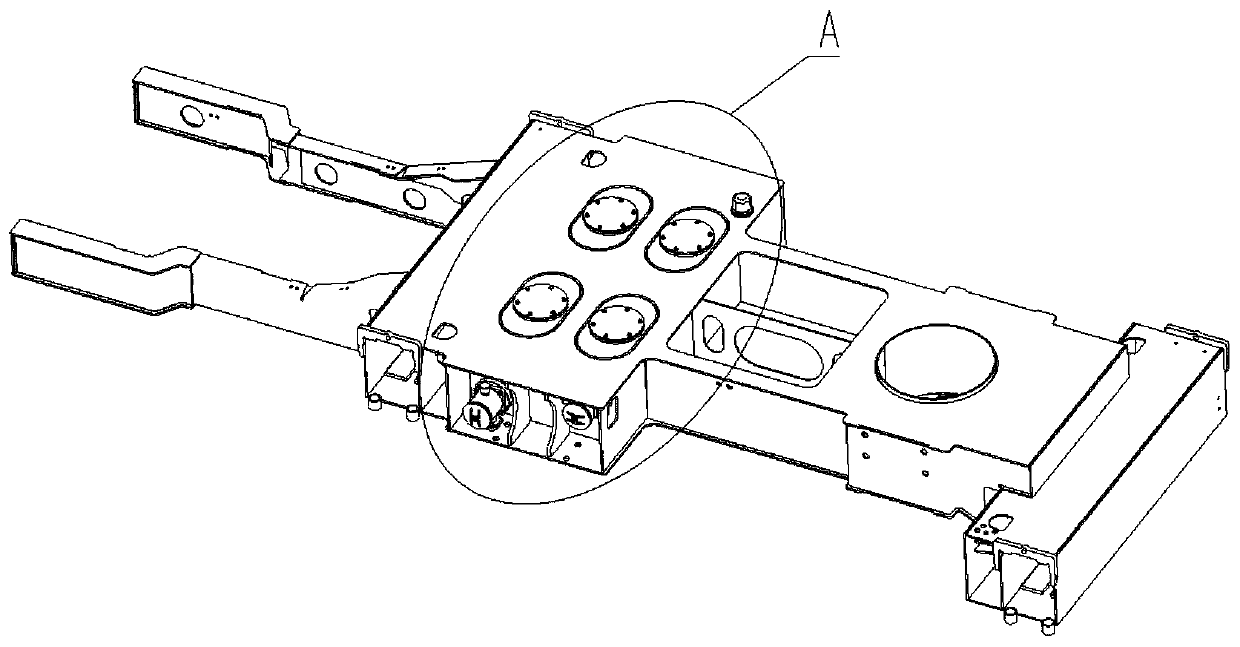

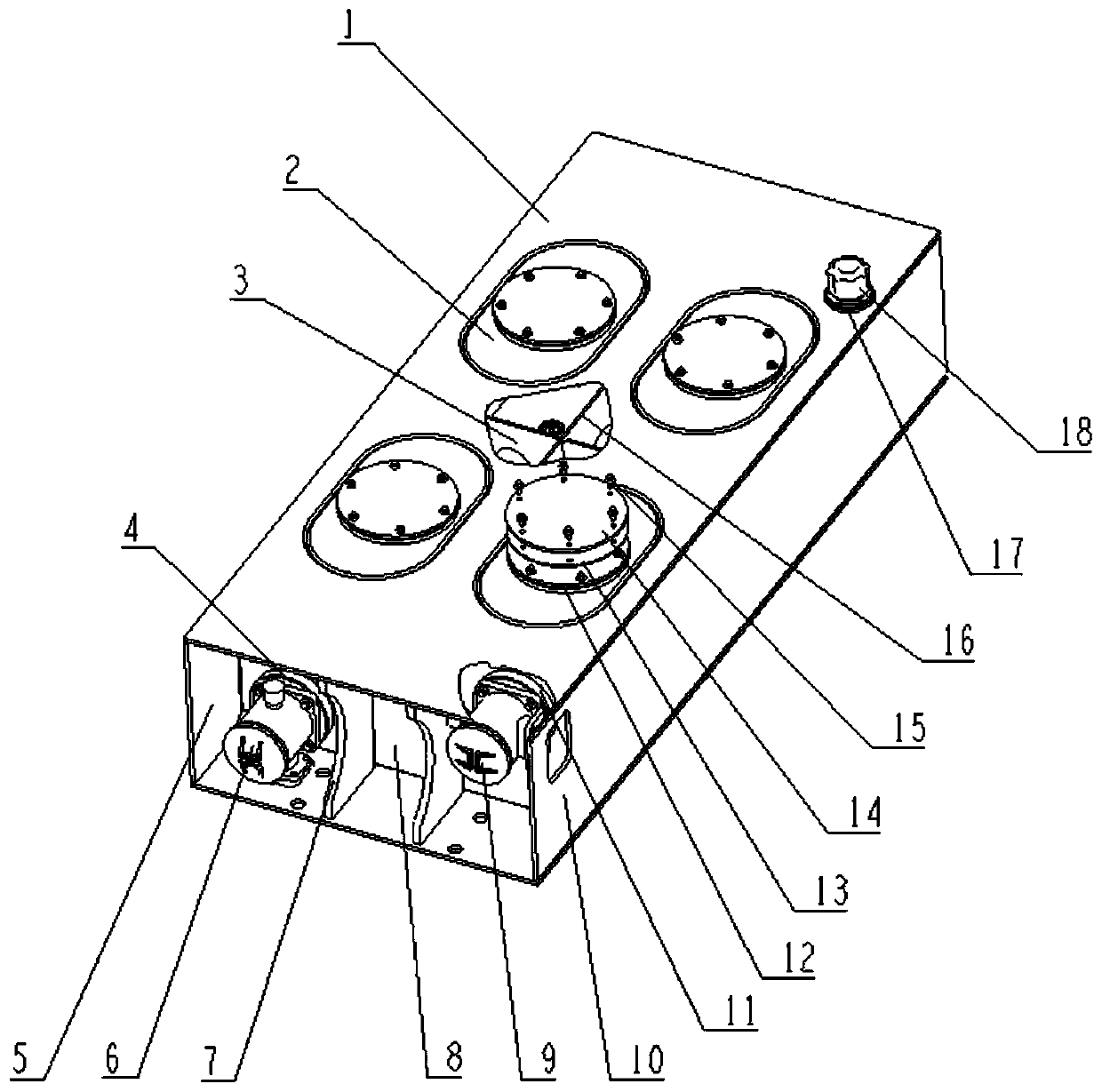

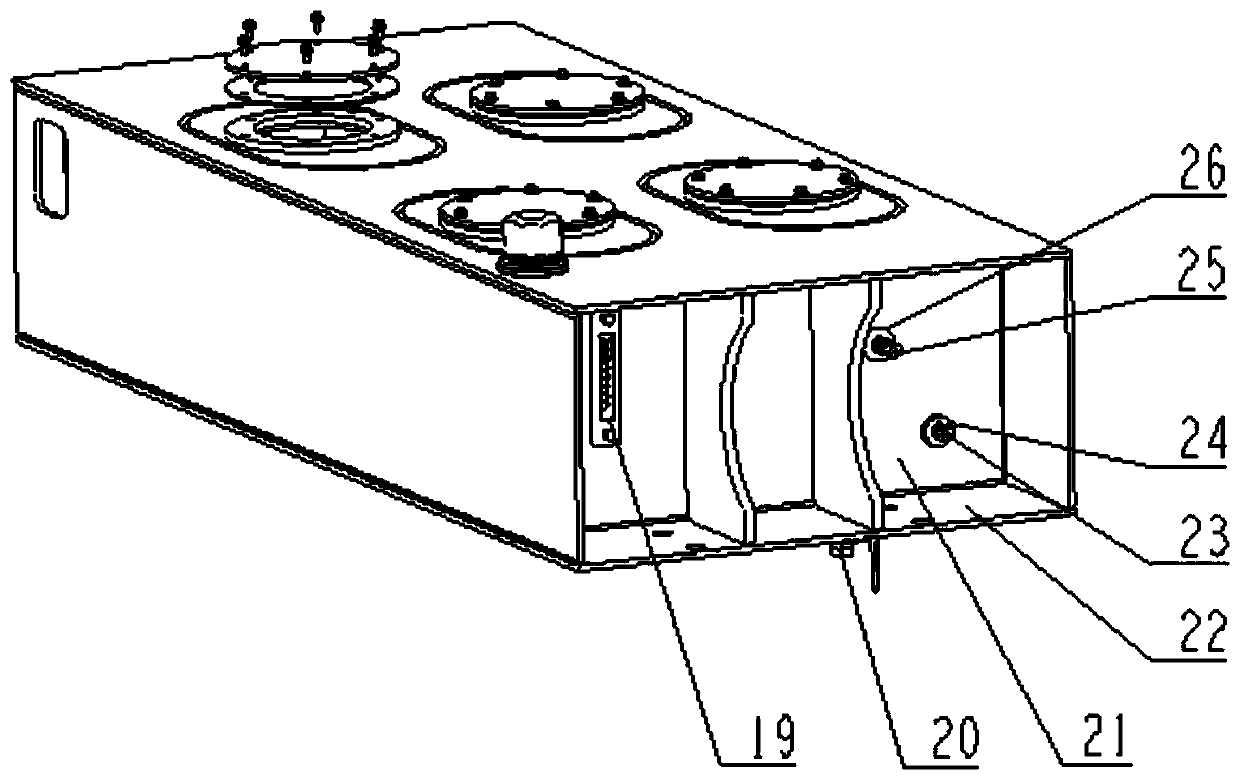

[0035] In some embodiments, a built-in integrated hydraulic oil tank is located in the middle of the frame and is surrounded by a box-shaped structure, such as figure 1 As shown, area A is the embedded integrated hydraulic oil tank of this embodiment, including upper cover plate 1, upper cover plate sealing plate 2, longitudinal partition 3, oil suction flange 4, front vertical plate 5, oil suction filter 6, Rib plate 7, left vertical plate 8, oil return filter 9, rear vertical plate 10, oil return flange 11, gland flange 12, rubber gasket 13, cover plate 14, bolt 15, transverse partition 16, oil injection Hole flange 17, air filter 18, liquid level liquid temperature gauge 19, oil drain valve 20, right vertical plate 21, lower bottom plate 22, liquid temperature flange 23, liquid temperature alarm sensor 24, liquid level flange 25, liquid level alarm sensor 26, such as figure 2 , image 3 shown.

[0036] like figure 2 , image 3 As shown, the box-shaped space composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com