Drainage Construction Method of Reversed Slope TBM Excavation Tunnel

A construction method and tunnel technology, applied in drainage, earthwork drilling, mining equipment, etc., can solve problems such as no water to pump, sediment accumulation, serious problems, etc., and achieve the effects of reducing pumping distance, reducing investment, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

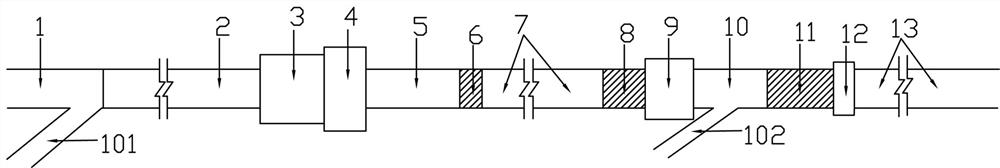

[0033] Embodiment 1: For the anti-slope TBM excavation tunnel drainage construction method of a certain project, see the TBM construction section figure 1 , using a Φ8.02m open hard rock roadheader for construction.

[0034] The construction section is located in the downstream of the reservoir 1. The construction section of the main tunnel is from the No. 3 branch tunnel 101 to the 1942m downstream of the extension section 2 of the main tunnel, with a total length of 18.275km. 100m), main engine assembly hole 4 (80m), first deployment hole 5 (200m), first departure hole 6 (25m), TBM first tunneling section 7 (8310m), upstream connection section 8 (1500m), maintenance Hole 9 (60m), the second entry hole 10 (240m), the downstream connecting section 11 (1500m), the second starting hole 12 (25m) and the second tunneling section 13 of TBM (6235m).

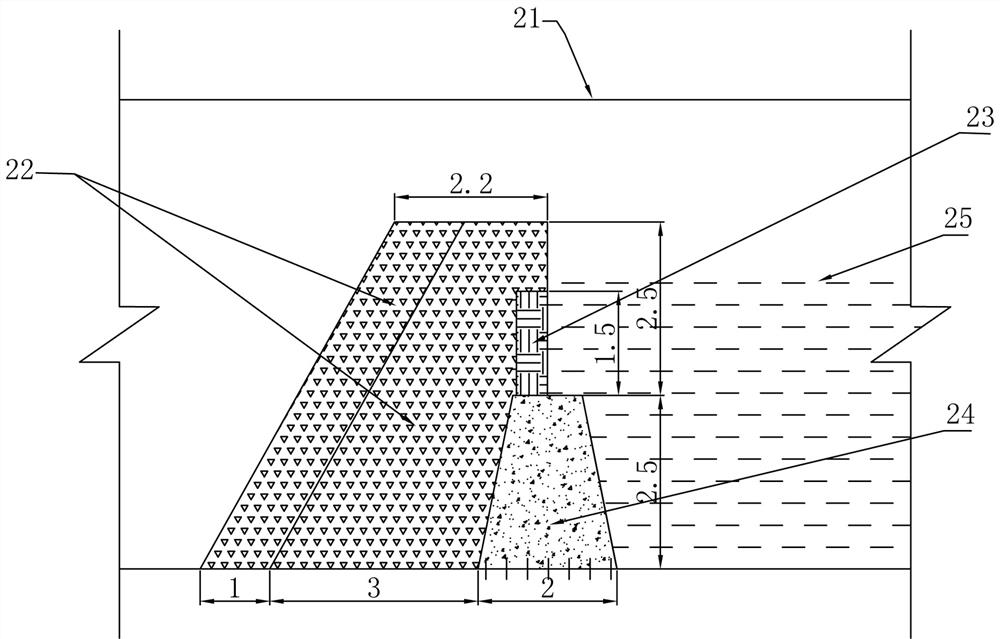

[0035] The horizontal distance of No. 3 branch tunnel 101 is 3872m, the slope distance is 3885m, and the comprehensive slope is 8.18...

Embodiment 2

[0133] Embodiment 2: Drainage scheme of the branch hole, on the basis of Example 1, drain water through the branch hole.

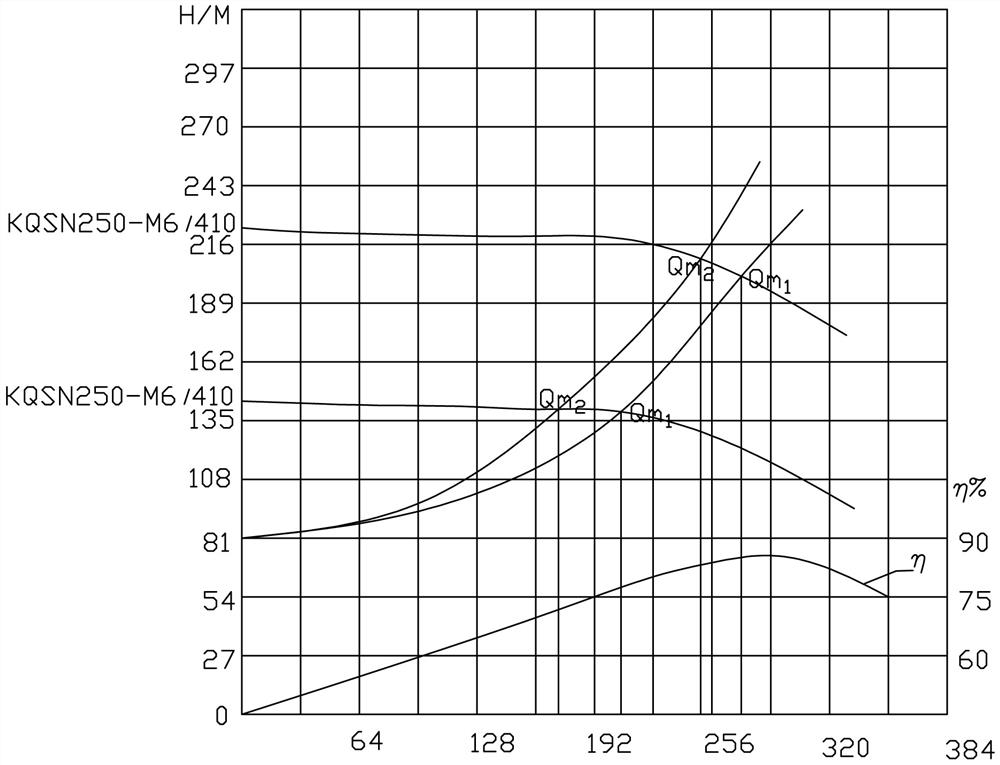

[0134] Drainage scheme of 2# branch tunnel: add a 300mm drainage pipeline (No. 3) on the basis of the original two 300mm drainage pipelines (No. 1 and No. 2 pipelines, which can only be used after partial treatment) in 2# branch tunnel , No. 1 and No. 2 pipelines are pumped out of the cave with two-stage drainage, and No. 3 is pumped to the top with one pump and directly pumped out of the cave. Pipeline No. 1 is equipped with a MD280-215 water pump at the bottom of the cave to discharge to the original 2# water tank in the 2# branch cave, and a MD280-172 water pump is installed in the original 2# water tank to pump out the cave; No. 2 pipeline is in One set of MD250-151 water pump is installed at the bottom of the cave to pump and discharge to the original 3# water tank of the 2# branch cave, and one set of MD280-172 water pump is installed at the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com