Method for installing automatic car washing machine

An automatic car washing and installation method technology, which is applied in the field of machinery, can solve the problems of large water pollution, low cleaning efficiency, and high requirements for on-site installation workers, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is used to disclose the specific content of the present invention so that those skilled in the art can realize the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

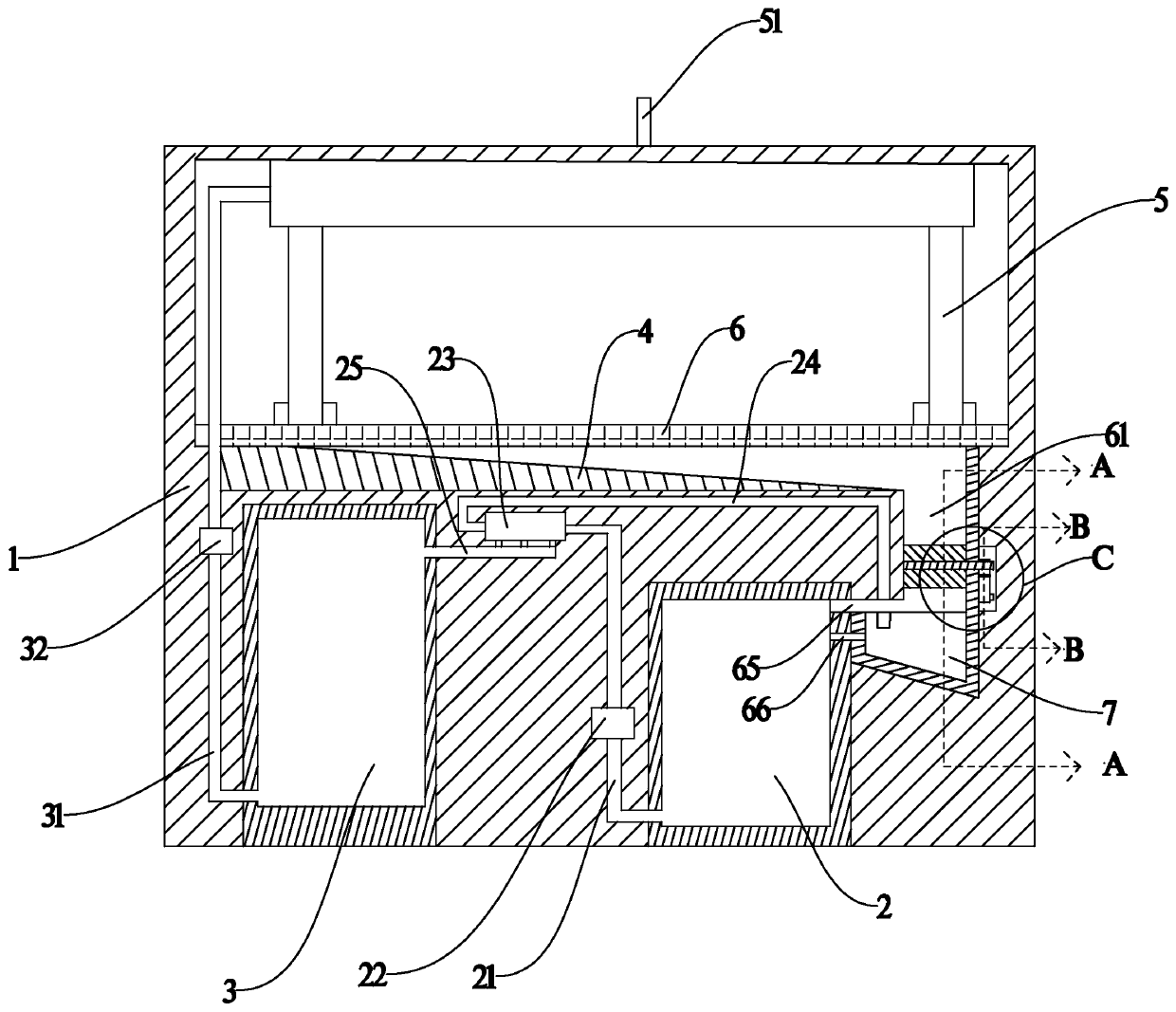

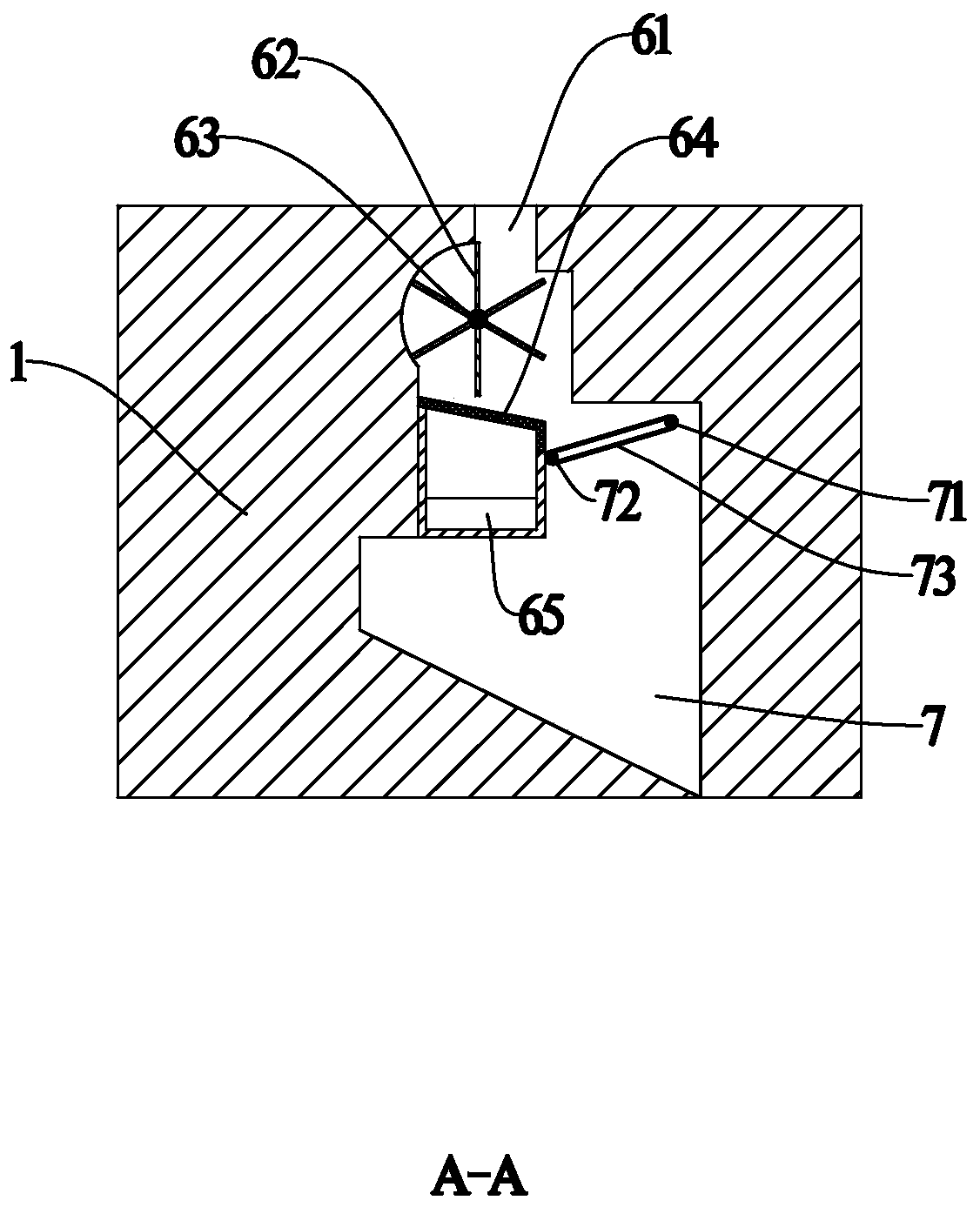

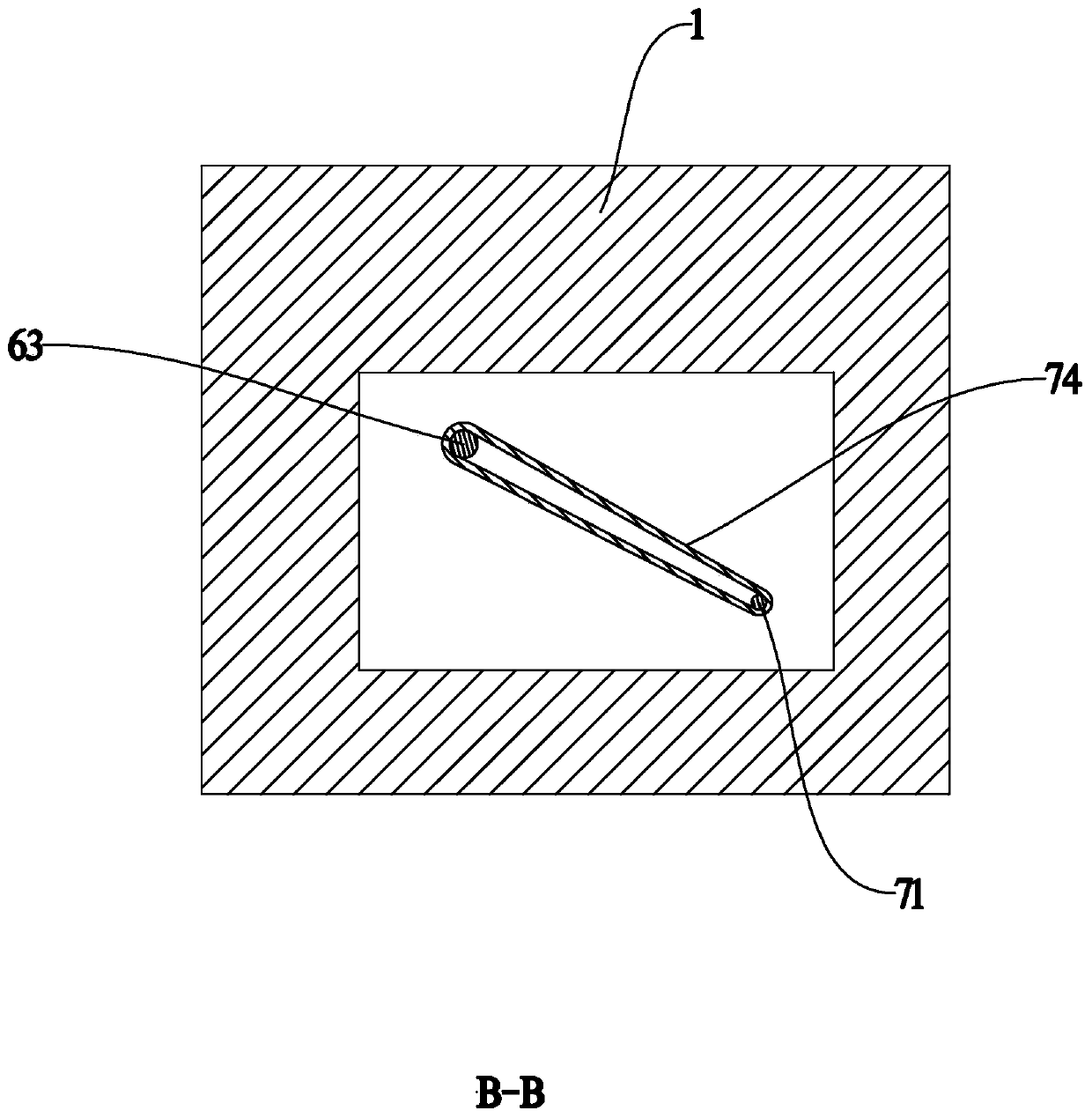

[0027] An embodiment of the present invention is an installation method of an automatic car washing machine, including the installation of a filtered water circulation system, a solid particle collection and discharge device, a sewage coarse filter device, a ground sewage collection device, a car washing platform, and an automatic car washing machine. The installation method Including the following steps: the whole installation steps are installed in sequence from bottom to top.

[0028] In this embodiment, the main body structure of the automatic car washing machine, the automatic control of the automatic car washing, and the power supply devices are prior art, and will not be describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com