All-position automatic welding walking device and track

An automatic welding and walking device technology, which is applied in the direction of welding accessories, electrode support devices, electrode clamp support devices, etc., can solve the problems of complex structure, high maintenance cost, and affecting installation efficiency, etc., and achieve compact internal design, convenient installation, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

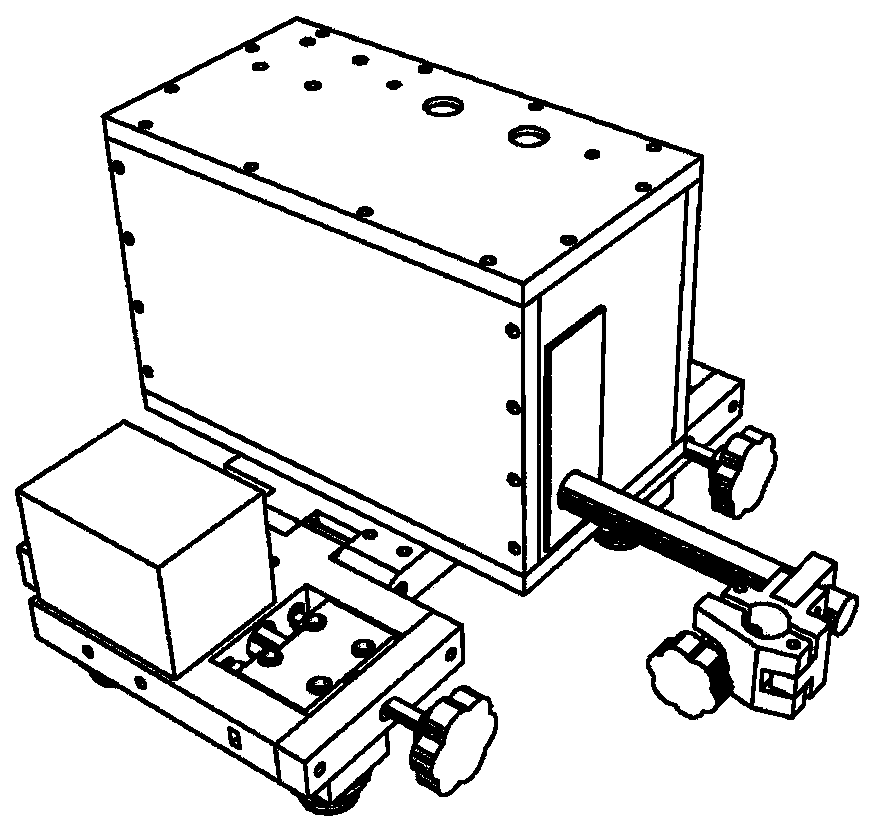

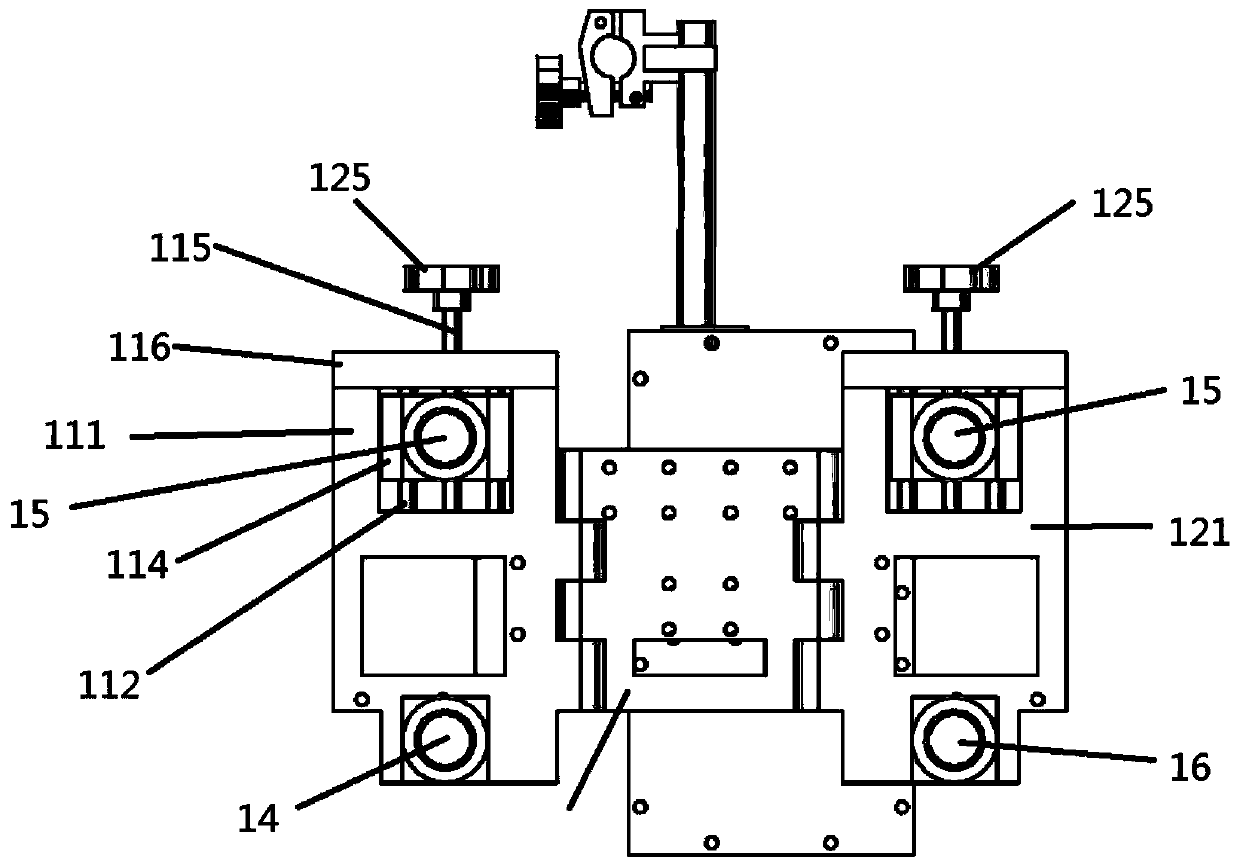

[0043] An all-position automatic welding walking device, used for walking on a track with teeth on one side, including: a front frame assembly, a rear frame assembly, and a rear frame assembly connected between the front frame assembly and the rear frame assembly the middle frame;

[0044]The front frame assembly includes a front frame 121, a first driven wheel 15 on one side below the front frame 121, a second driven wheel 16 on the other side below the front frame 121, and a wheel for adjusting the first driven wheel. 15 and the driven wheel displacement adjusting device of the distance between the second driven wheel 16;

[0045] Described rear vehicle frame assembly comprises rear vehicle frame 111, the driving wheel 14 of one side below rear vehicle frame 111, the first driven wheel 15 of the other side below rear vehicle frame 111, and is used for adjusting the first driven wheel 15 and The driven wheel displacement adjustment device for the distance between the driving...

Embodiment 2

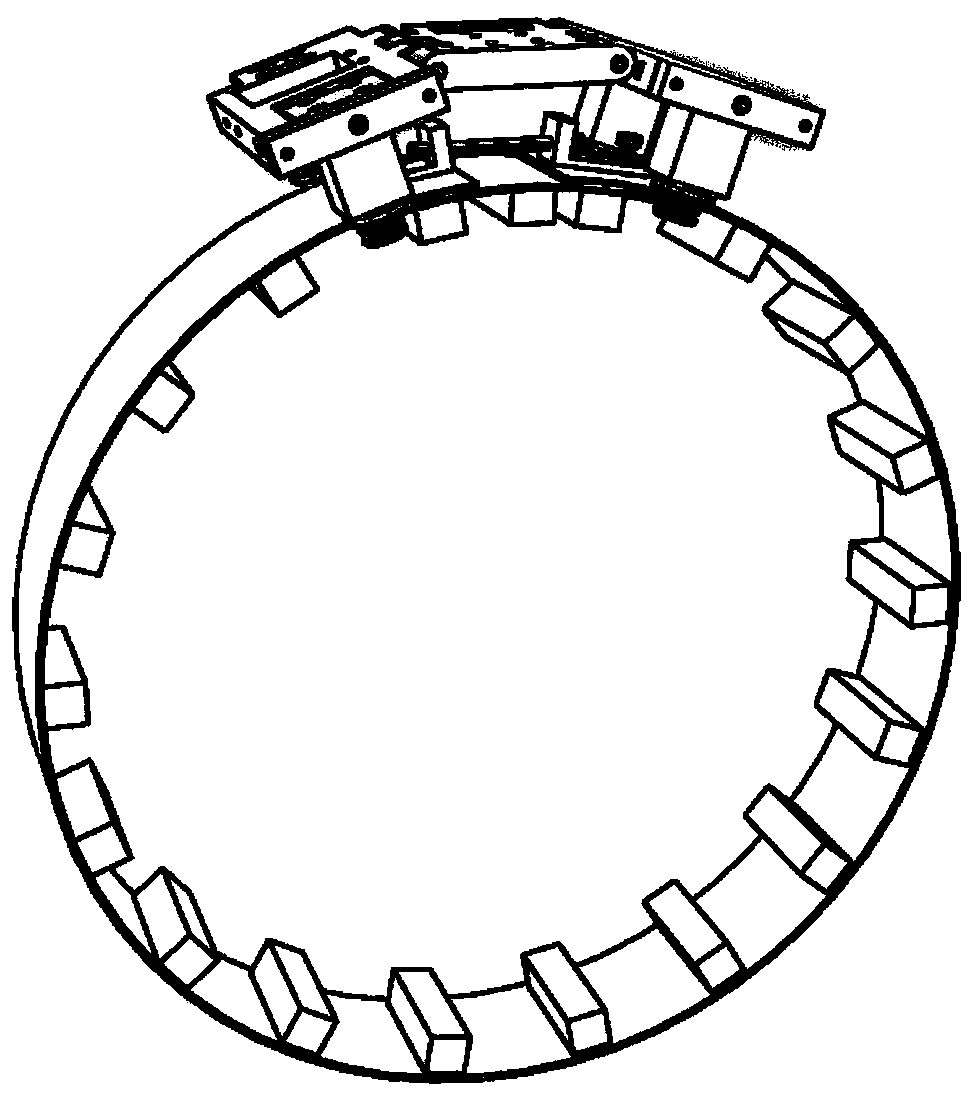

[0060] Such as Figure 10 As shown, this embodiment also provides a track of the all-position automatic welding traveling device, which is used to make the full-position automatic welding traveling device walk on it. The position of the track corresponds to the position of the guide groove of the second layer. The teeth of the upper layer of the track are meshed with the gears in the guide groove of the second layer. The gears in the slots mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com