Spinning nozzle detection system and control method thereof

A detection control and detection system technology, applied in the field of fiber tow production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

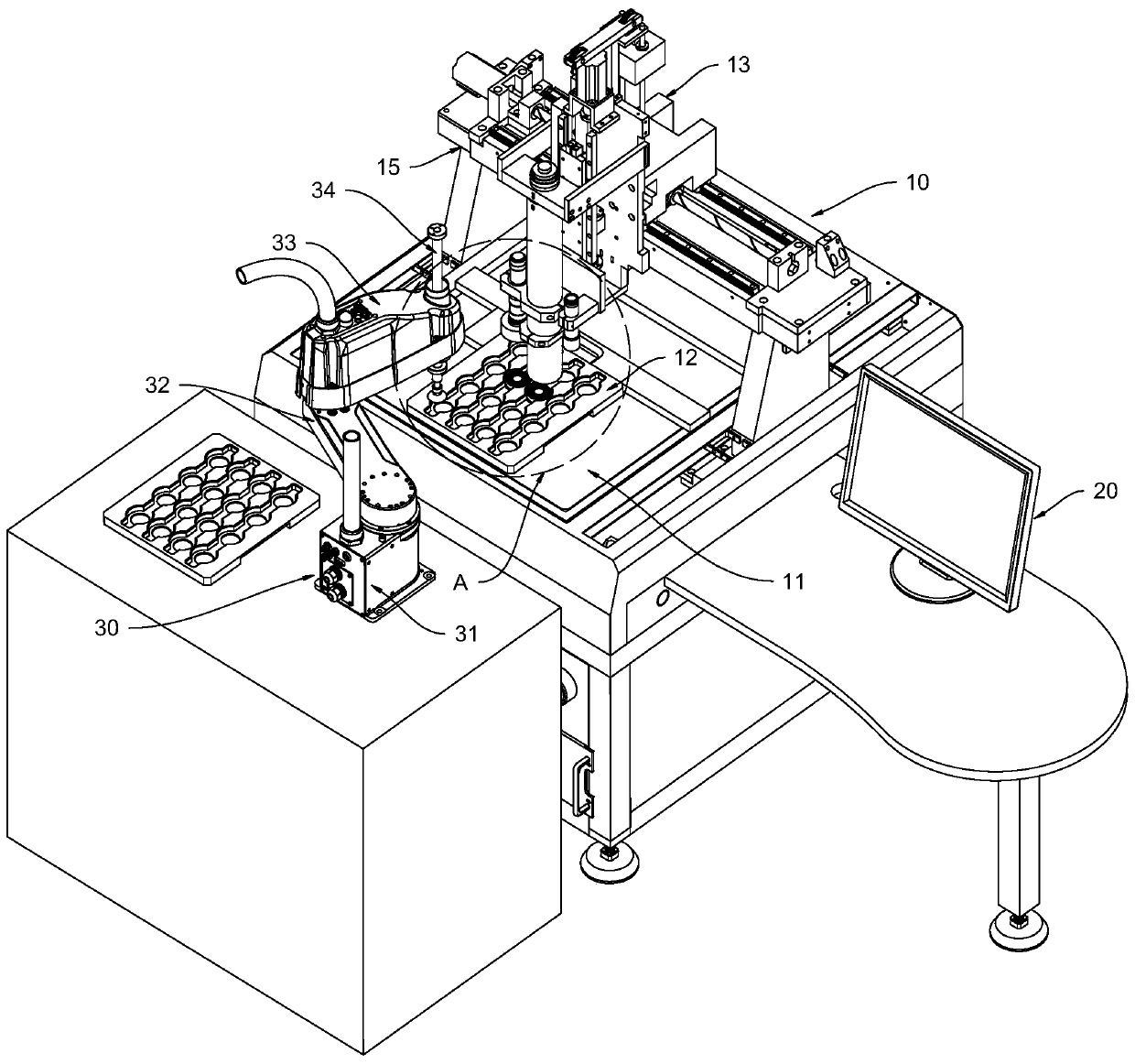

[0032] see Figure 1 to Figure 3 The spinneret detection system provided by the present invention includes a detector 10, a detection control device 20 and a manipulator 30, the detection control device 20 is connected to the detector 10 and the manipulator 30 in communication, and the detector 10 is used to take images of the spinneret.

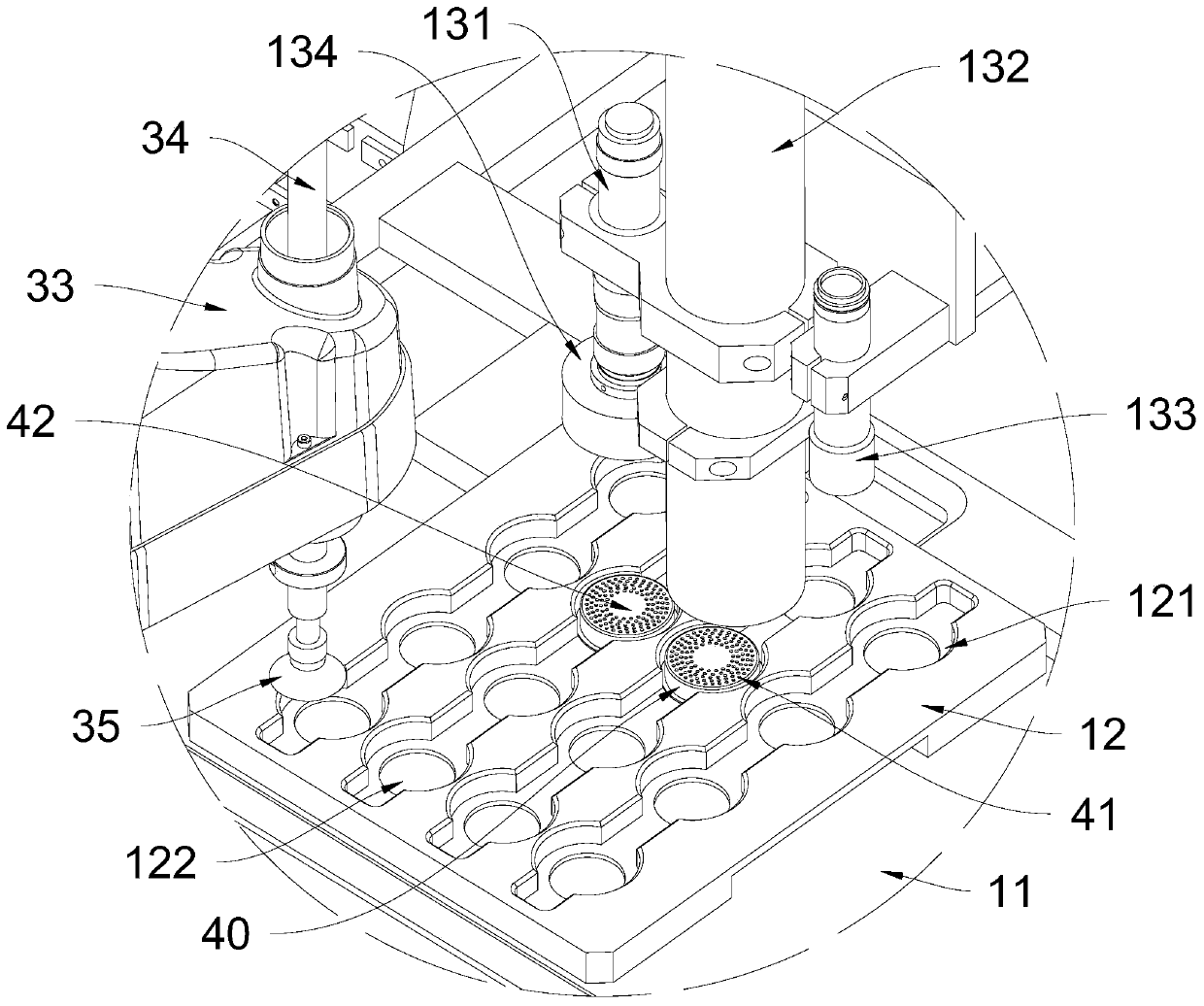

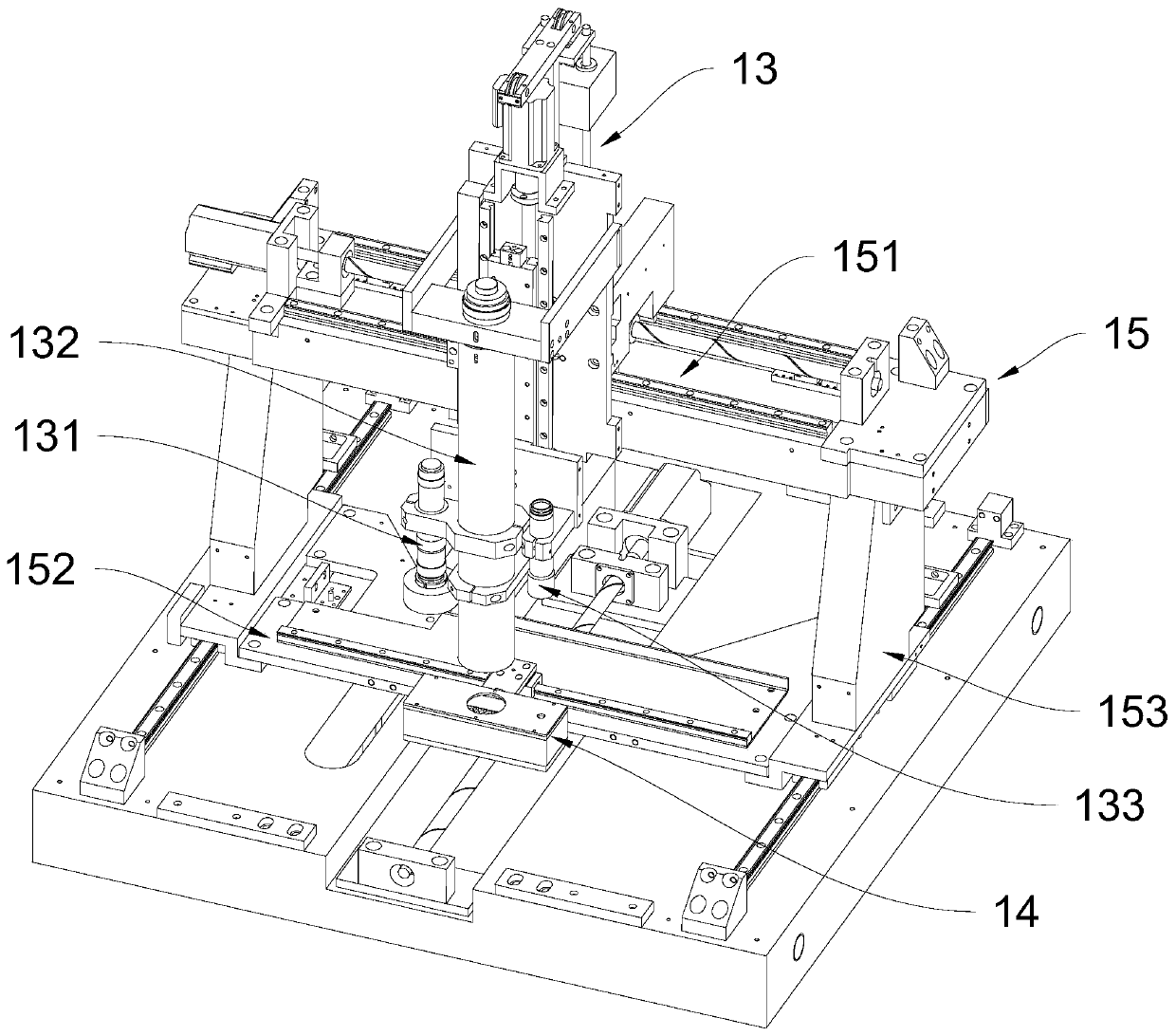

[0033] The detector 10 includes a transparent panel 11 , a positioning tray 12 , a detection head 13 and a tracking light source 14 . The positioning tray 12 is arranged on the light-transmitting panel 11, and the positioning tray 12 is provided with a plurality of positioning holes 121 that cooperate with the spinneret 40, and the bottom of each positioning hole 121 is provided with a light-transmitting hole 122 on the positioning tray 12. The positioning holes 121 are distributed in a matrix on the positioning tray 12 . The detection head 13 is located above the light-transmitting panel 11, and the detection head 13 can move along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com