Screw device and hand-held screw system

A device and manual technology, applied in the direction of wrenches, power tools, screwdrivers, etc., can solve the problems of impossibility, difficult to measure the shaft torsion shaft, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

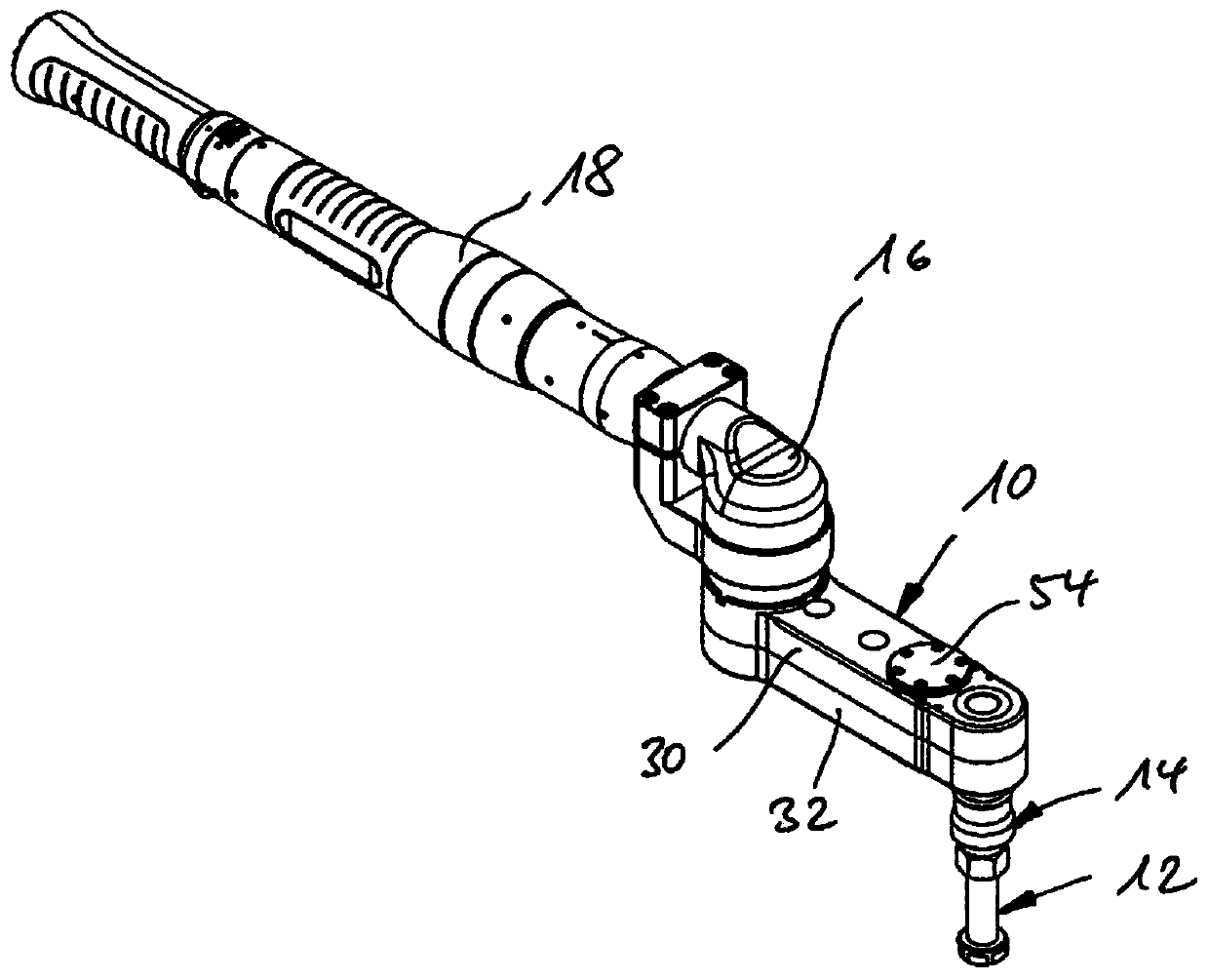

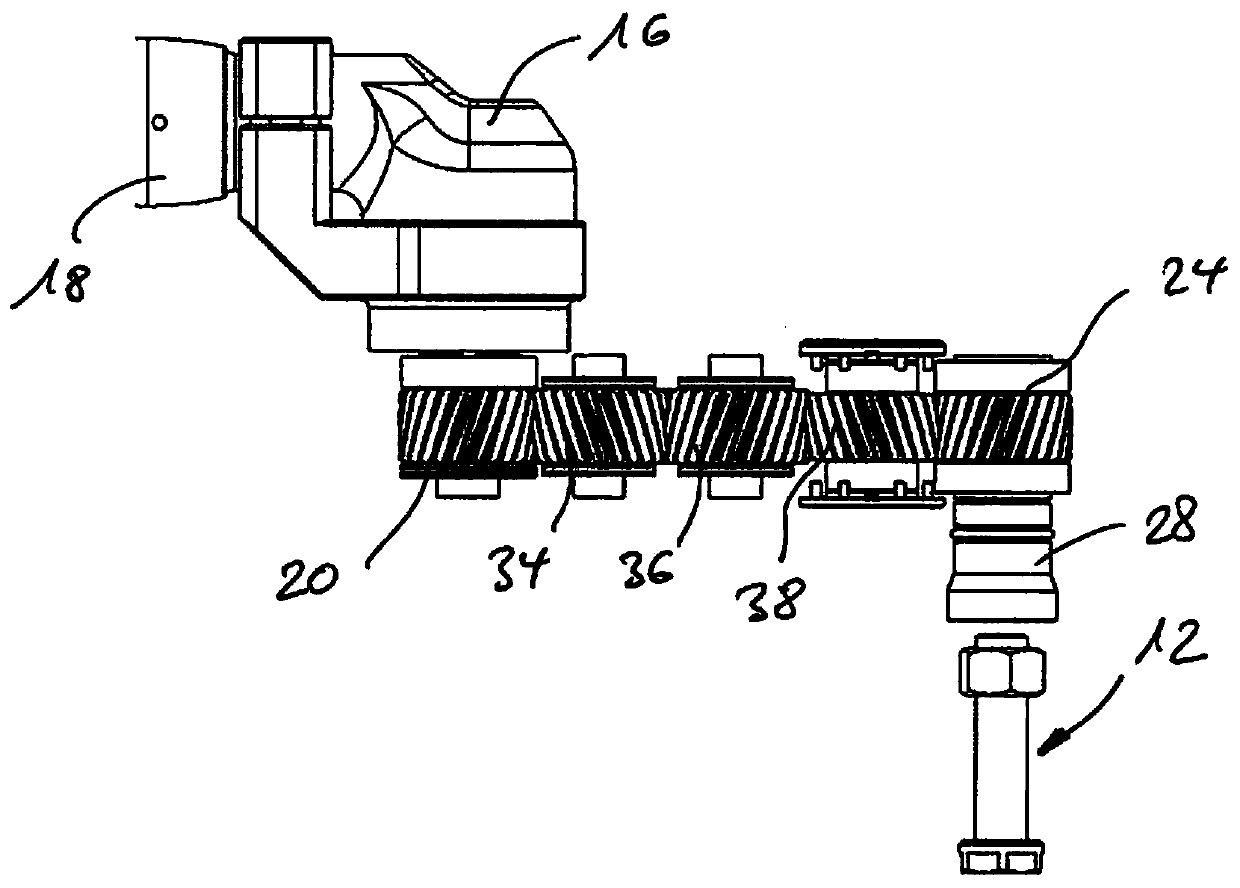

[0025] figure 1 A screwing device for applying torque to a pair of screws according to a first embodiment of the invention is shown in perspective view, having a flat output device 10 accommodated in a housing 30, 32, one end (output side ) to drive a suitable screwing tool 14 in cooperation with the screw 12 as a pair of screws (not belonging to the invention). On the drive side, ie at the opposite end from the output of the flat output device, they pass through a goniometer head 16 with a pair of bevel gears and a manually operable screwing tool 18 as a commercially available Tools, and tools supplied by various tool manufacturers, will be input via a motor (e.g. electric or pneumatic), deflected at right angles via an assembly 16, into a flat output device 10, which in the manner described below will This drive is transmitted to the tool 28 for the screwing operation of the connecting element 12 .

[0026] In particular, refer to Figure 2 to Figure 4 A side view and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com