Large-power motor hanging installation structure

An installation structure and motor technology, applied in the field of motors, can solve the problems of insufficient thread bearing capacity, affecting the use of equipment, and heavy motor weight, etc., and achieve the effects of increasing the stability of the equipment, enhancing the service life, and increasing the strength of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

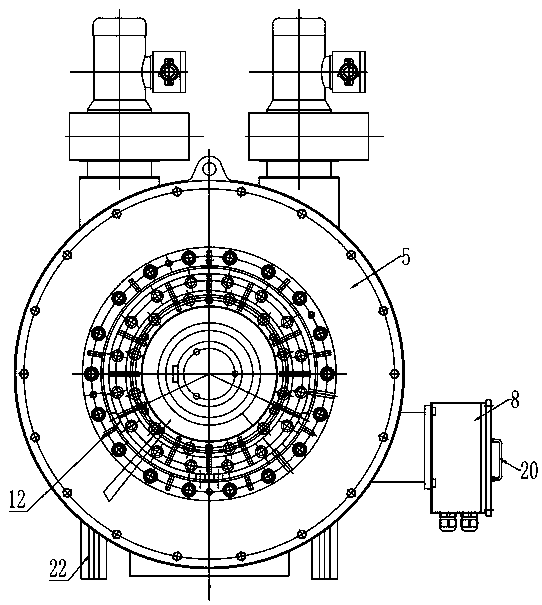

[0024] Embodiment 1: According to Figure 1-5 It can be seen that a high-power motor suspension installation structure includes a motor body 1 and an input shaft 2 arranged on the motor body 1. The input shaft 2 is provided with a shaft key 3 and a keyway matching the shaft key 3. The outer side of the input shaft 2 A shaft sleeve 4 is set in the sleeve, and the shaft sleeve 4 is covered with an organic base 5. An air inlet 6 is provided under the base 5, and external air can enter from the air inlet 6 from bottom to top. To the right, it is discharged from the air outlet 7. A junction box 8 is installed on the side wall of the machine base 5. An equipment bearing sleeve 9 is set on the side of the input shaft 2 close to the motor body 1. A fixing ring 10 is provided on the outside of the equipment bearing sleeve 9. The equipment bearing sleeve The centering flange 11 is fixedly connected to the outer circle of 9, and the centering flange 11 is positioned through the outer cir...

Embodiment 2

[0025] Embodiment 2: According to Figure 6-7 It can be seen that, in order to ensure the stability of the motor performance in the case of user-specific and large torque, B35 type installation can also be adopted, by adding feet under the process support 22 to form a foot connection, and the rest of the embodiments are the same as in Embodiment 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com