Plane thrust ball bearing automatic ball injection riveting machine

A thrust ball bearing and riveting machine technology, applied in the field of thrust ball bearings, can solve problems such as low work efficiency, worker fatigue, and consumption, and achieve the effects of improving production efficiency, ensuring product quality, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

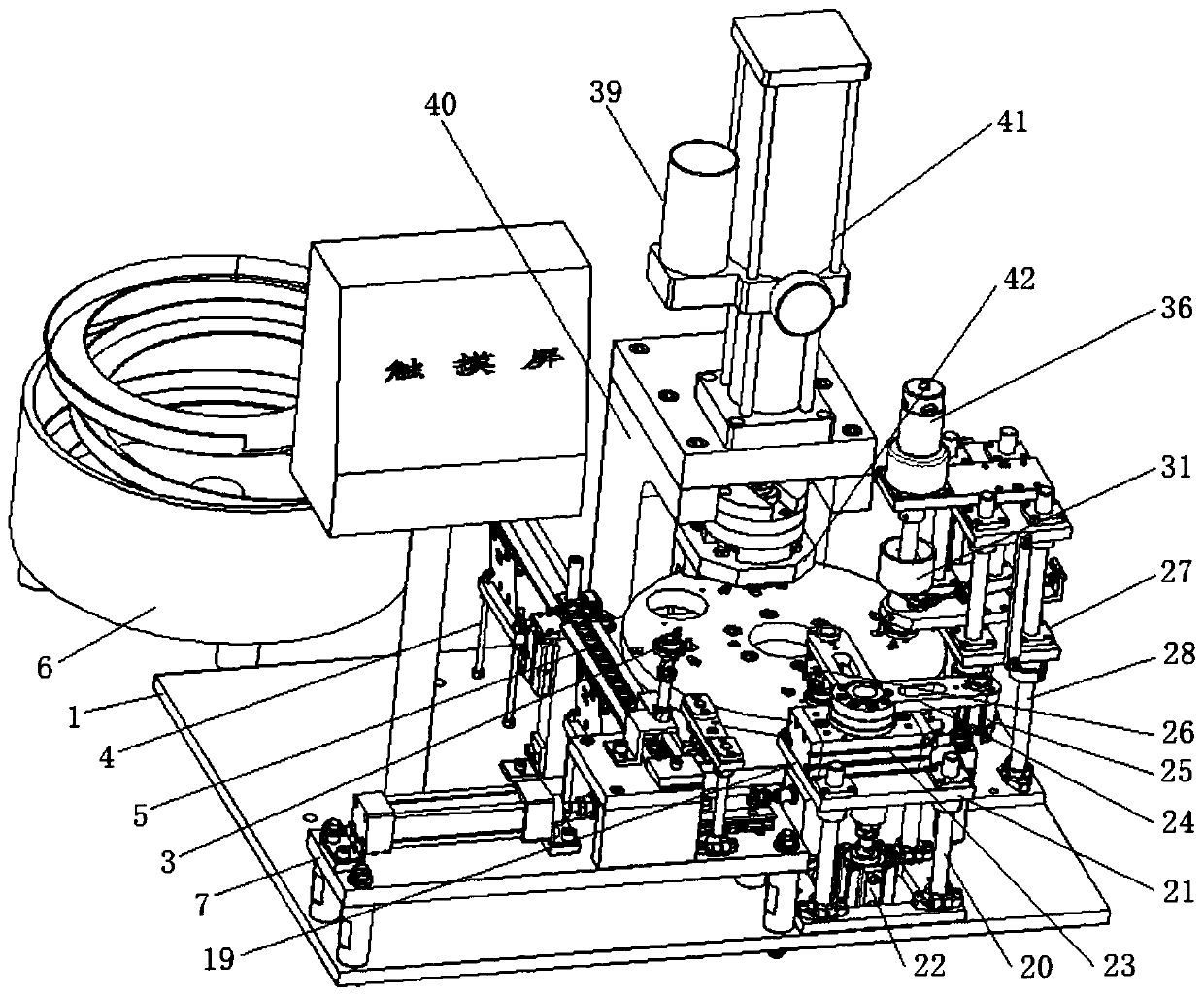

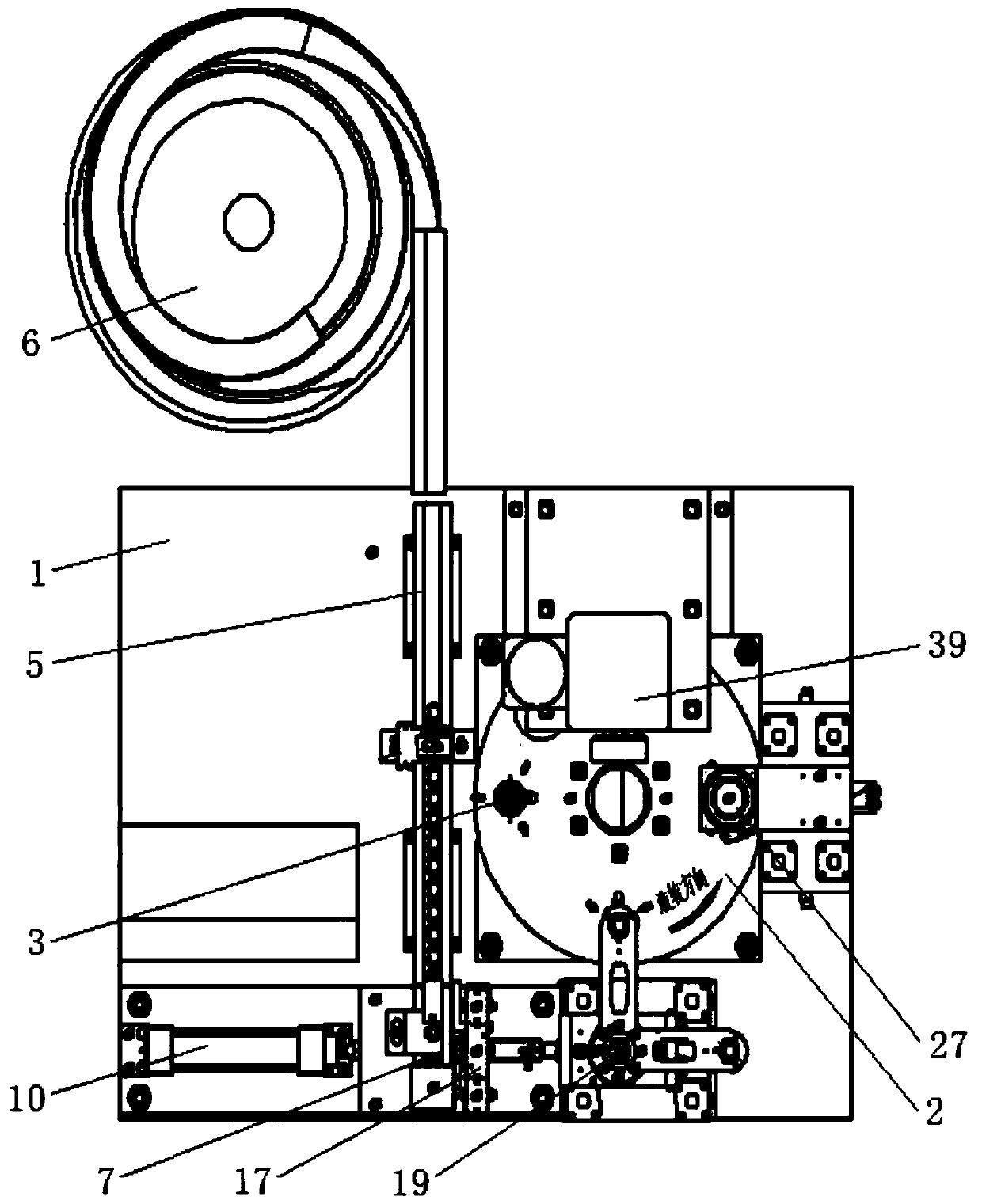

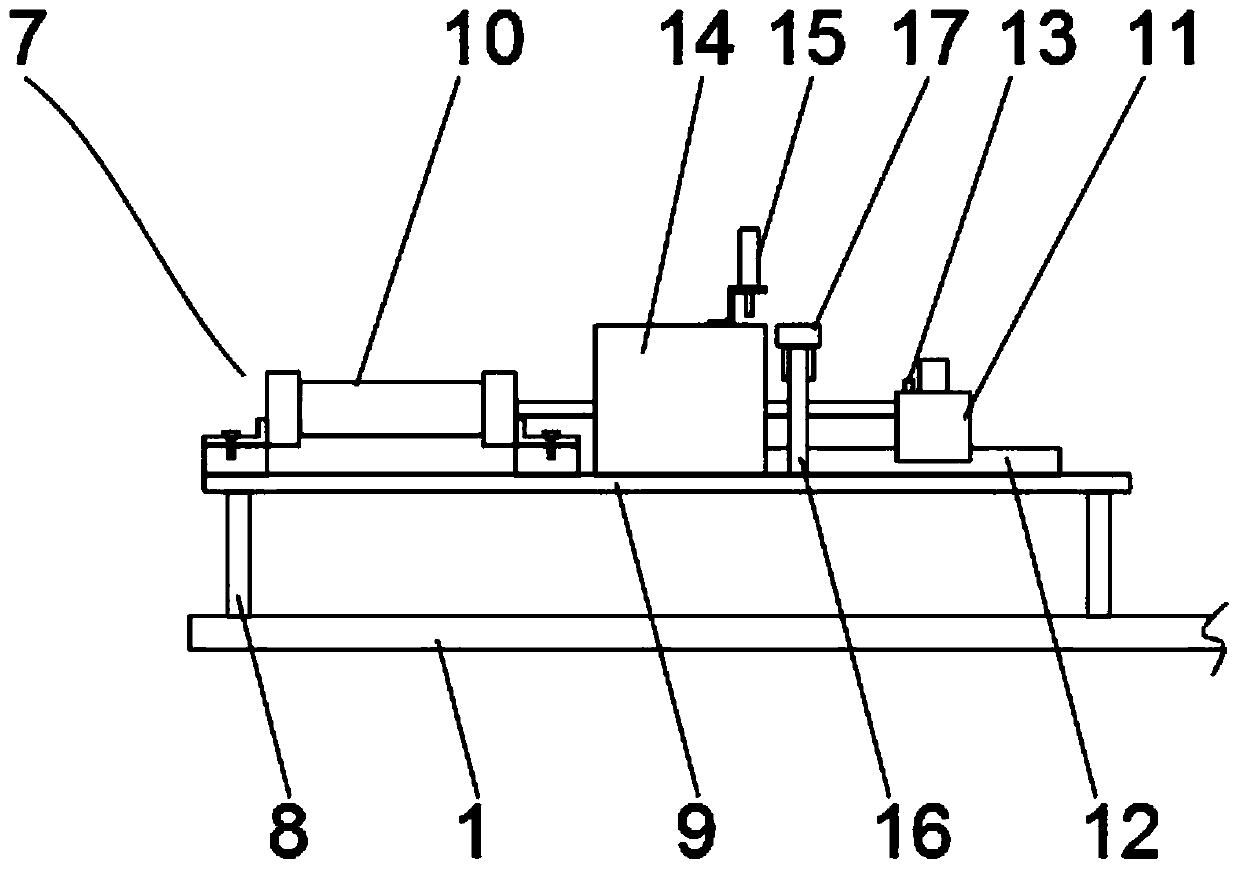

[0032] Embodiment one, by figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6Given, the present invention includes a workbench 1, the middle part of the upper end of the workbench 1 is rotatably connected with a turntable 2, which is convenient to drive the lower mold base 3 for rotary motion, and the upper end of the turntable 2 is circumferentially connected with the lower mold base 3, which is convenient for the cage to operate, and the turntable One side of 2 is connected with a linear feeder 5 through a support rod 4, which is convenient for conveying the cage to be riveted. One end of the linear feeder 5 is connected with a vibrating plate mechanism 6 with respect to the side of the workbench 1, through which the vibrating plate mechanism 6 is convenient. Orient the cage so that it keeps the front facing up. The other end of the linear feeder 5 is connected to an automatic feeding positioning device 7. The automatic feeding positioning device 7 incl...

Embodiment 2

[0033] Embodiment 2, on the basis of Embodiment 1, the number of lower mold bases 3 is four, and the angle between adjacent lower mold bases 3 is 90° with respect to the center of the turntable 2, which is convenient for loading and unloading workpieces after riveting the device. efficiency.

Embodiment 3

[0034] Embodiment 3, on the basis of Embodiment 1, the feeding seat 11 is a convex cylinder, and the contact end of the feeding seat 11 and the slide rail 12 is provided with a corresponding chute, and the convex columnar structure is set to facilitate the cage Placed on the upper end of the feeding seat 11, the setting of the chute is convenient to cooperate with the slide rail 12 to slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com