A stone processing equipment for bridge construction

A technology for processing equipment and stone materials, applied in grain processing, solid separation, cleaning methods and appliances, etc., can solve problems such as easy blockage of materials, crushing equipment does not have dust removal function, etc., and achieves the effect of ensuring the efficiency of power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

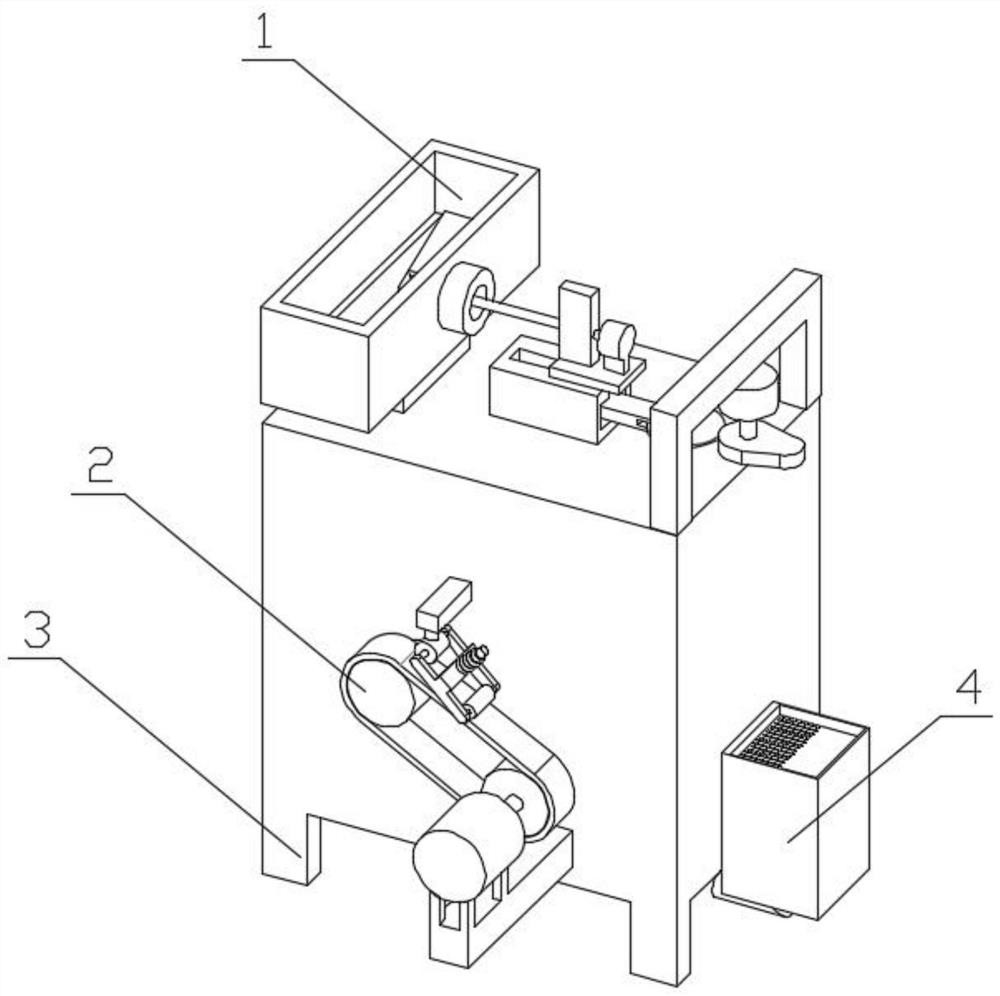

[0038] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 Describe this embodiment, the present invention relates to a stone processing equipment, more specifically a stone processing equipment for bridge construction, including a feeding hopper mechanism 1, a crushing actuator 2, a fuselage mechanism 3, and a dust removal mechanism 4, the equipment can prevent When the material is blocked during feeding, the equipment can be crushed, the equipment can firmly fix the broken liner, the equipment can ensure the efficiency of power transmission, the equipment can perform secondary crushing and tertiary crushing, the equipment can remove dust, and the equipment can automatically clean dust.

[0039] The feeding hopper mechanism 1...

specific Embodiment approach 2

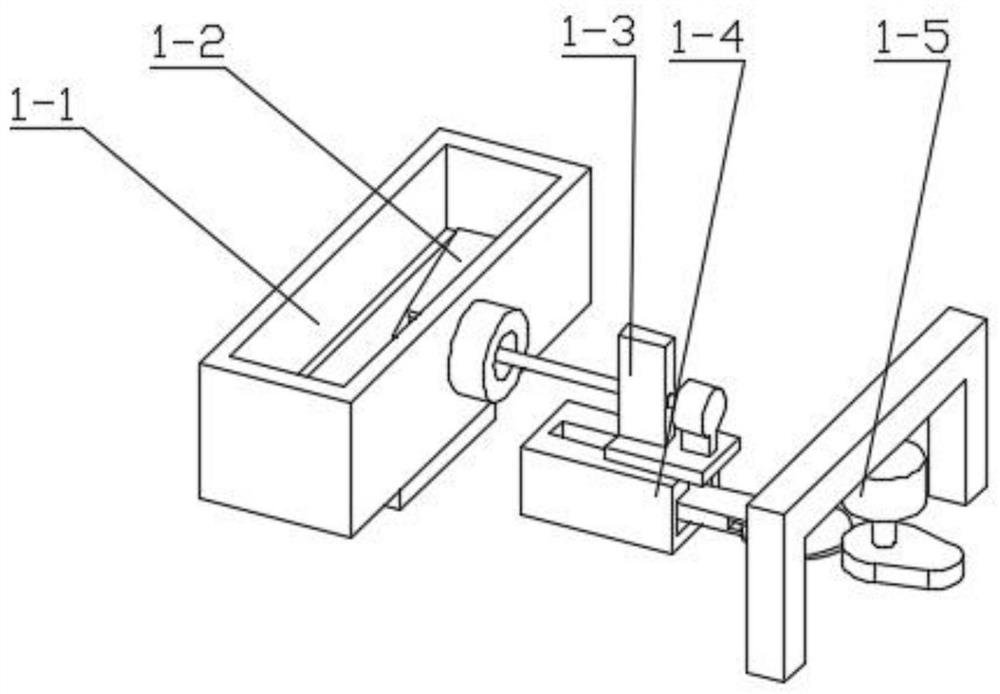

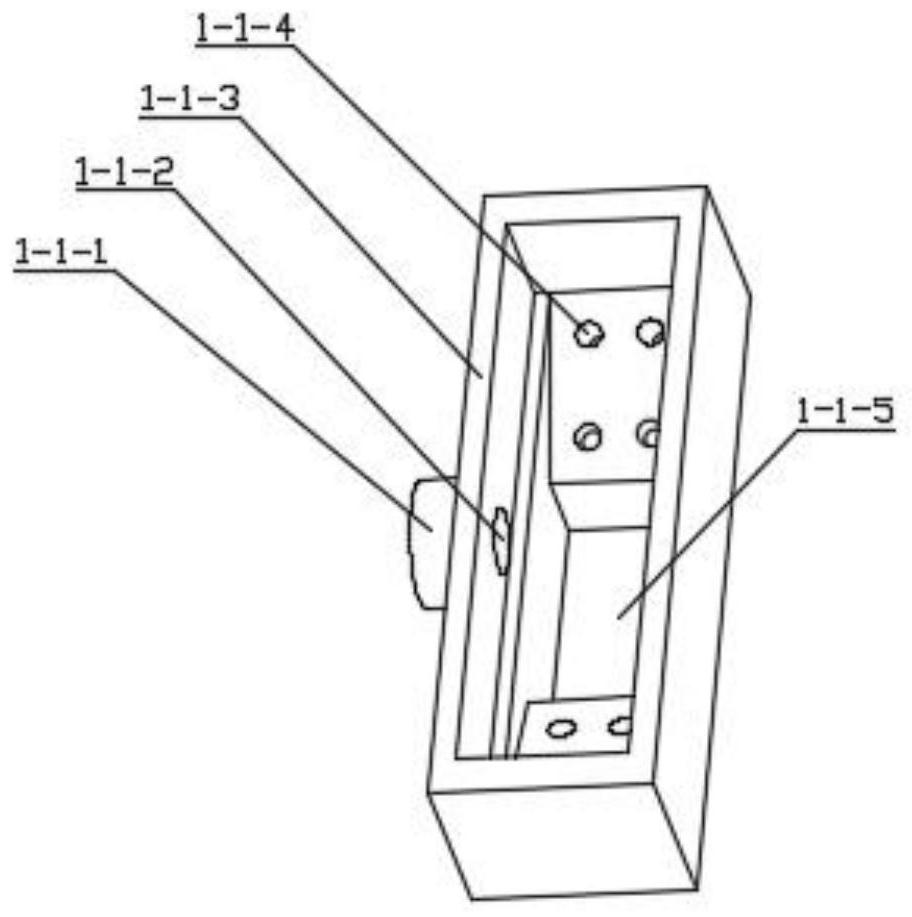

[0041] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 Describe this embodiment, this embodiment will further explain the first embodiment, the described feed hopper mechanism 1 includes a hopper mechanism 1-1, a movable liner mechanism 1-2, a drill mechanism 1-3, a movable seat mechanism 1-4, The driving mechanism 1-5, the hopper mechanism 1-1 cooperates with the movable lining mechanism 1-2, the drill bit mechanism 1-3 is connected with the movable seat mechanism 1-4, and the movable seat mechanism 1-4 cooperates with the driving mechanism 1-5 ; The hopper mechanism 1-1 includes an outer cylinder 1-1-1, an inlet 1-1-2, a bucket body 1-1-3, a sliding hole 1-1-4, an outlet 1-1-5, and an outer cylinder 1-1-2. 1-1 is connec...

specific Embodiment approach 3

[0043] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22Describe this embodiment, this embodiment will further explain Embodiment 1, the crushing actuator 2 includes a crushing motor support 2-1, a crushing motor 2-2, a crushing motor pulley 2-3, a belt 2-4, and a transmission pulley 2-5, tensioning mechanism 2-6, broken liner mechanism 2-7, anti-loose limit mechanism 2-8, rotating wheel mechanism 2-9, bolt 2-10, nut with limit groove 2-11, broken The motor support 2-1 is connected with the crushing motor 2-2, the crushing motor 2-2 is connected with the crushing motor pulley 2-3, the connection mode of the crushing motor pulley 2-3 and the belt 2-4 is a flexible connection, and the belt 2-4 The connection mode with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com