A port cargo stacking crane

A technology of goods and cranes, which is applied in the field of stacking cranes, can solve the problems that goods cannot be placed quickly and orderly, and the operation is complicated, so as to achieve the effect of quick placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

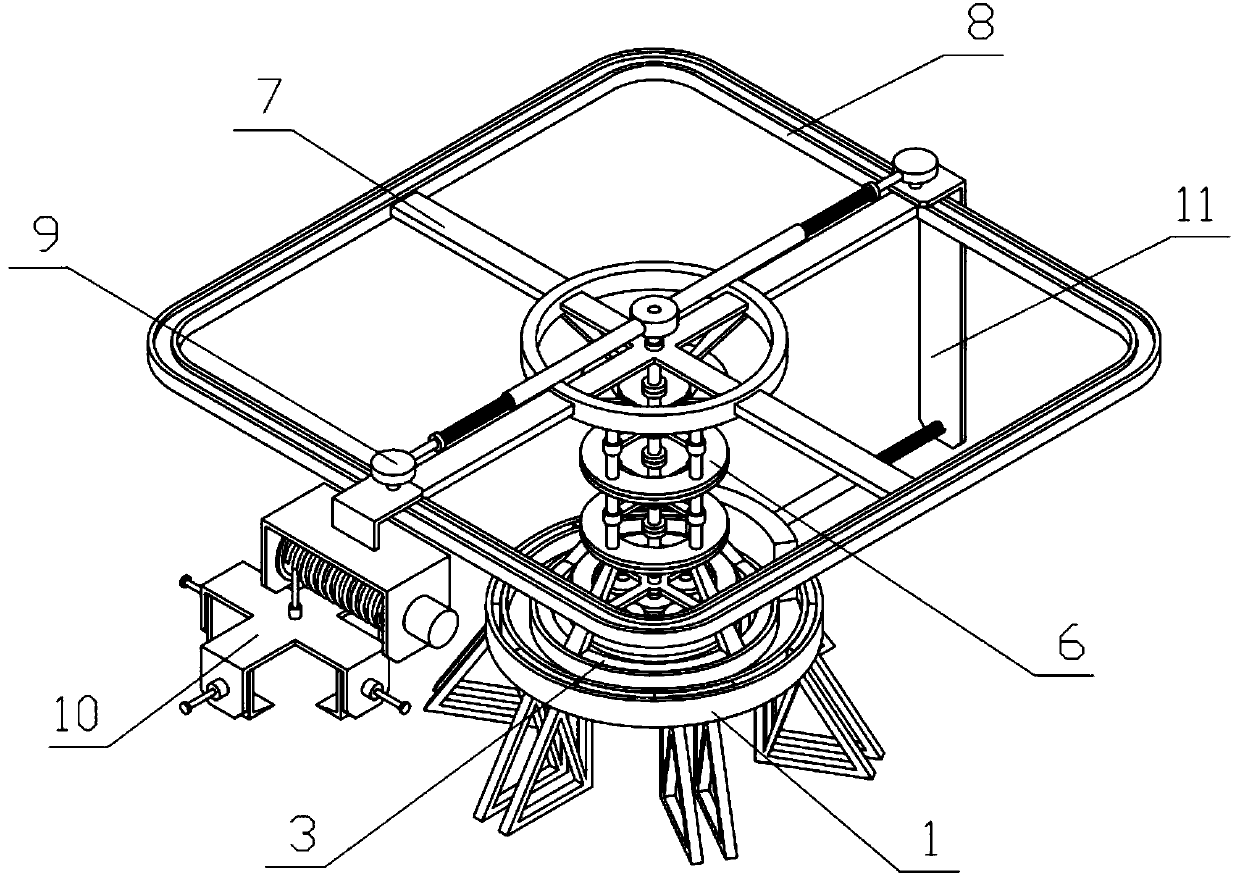

[0036] Combine below Figure 1-13Describe this embodiment, a port cargo stacking crane, including a supporting base 1, a rotating bracket 2, a mounting bracket 3, a planetary mechanism 4, a driving mechanism 5, a supporting bracket 6, a supporting top frame 7, a rectangular rail 8, and a pushing mechanism 9. The hoisting mechanism 10 and the counterweight mechanism 11, the supporting chassis 1 is rotatably connected with a rotating bracket 2, the rotating bracket 2 is fixedly connected with a mounting bracket 3, the rotating bracket 2 is provided with a planetary mechanism 4, and the driving mechanism 5 is fixedly connected On the planetary mechanism 4, a plurality of supporting brackets 6 are fixedly connected between the mounting bracket 3 and the supporting top frame 7, and the supporting brackets 6 are sequentially connected end to end, the driving mechanism 5 and the supporting bracket 6 are connected by transmission, and the supporting top frame 7 is fixedly connected. T...

specific Embodiment approach 2

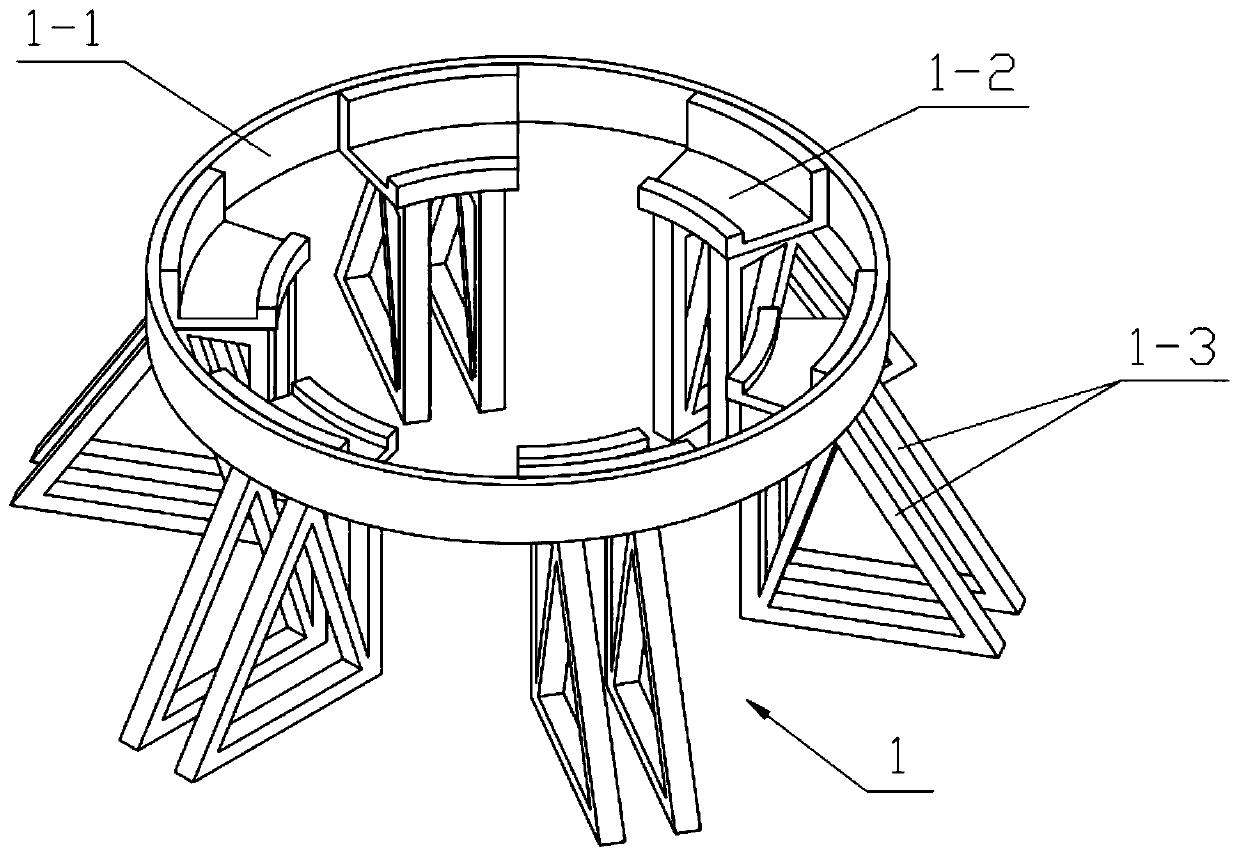

[0038] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1, the support chassis 1 includes a chassis ring 1-1, a circular arc track 1-2 and a support foot 1-3, and the chassis ring 1-1 is internally fixed A plurality of circular arc tracks 1-2 are connected, and a plurality of circular arc tracks 1-2 form a rotating track, and a plurality of circular arc tracks 1-2 are fixedly connected with two supporting feet 1-3, and the rotating bracket 2 is rotatably connected to multiple In the rotating track composed of two circular arc tracks 1-2, the rotating bracket 2 is transmission-connected to the output shaft of the drive motor Ⅰ.

specific Embodiment approach 3

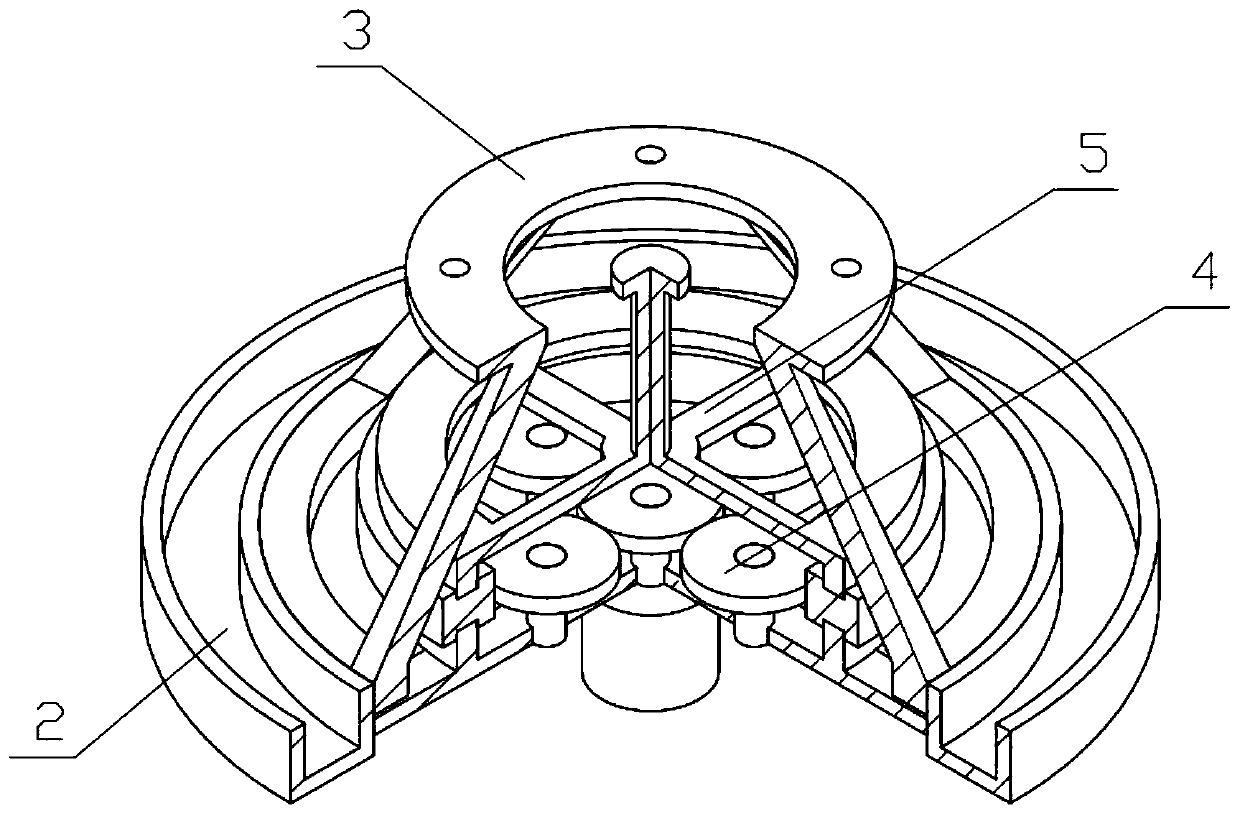

[0040] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the installation bracket 3 includes the installation bottom plate 3-1, the support rod 3-2 and the installation top plate 3-3, the installation bottom plate 3-1 is fixedly connected to the rotating bracket 2, a plurality of support rods 3-2 are fixedly connected between the installation bottom plate 3-1 and the installation top plate 3-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com