Circulation lifting and screening type multistage grain crushing device

A crushing device and grain technology, applied in the field of agricultural production, can solve the problems of drive structure design, processing quality efficiency defects in crushing structure, insufficient grain crushing effect, and fast drying of grain crumbs, etc., to achieve crushing quality The effect of improving and improving the processing quality and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

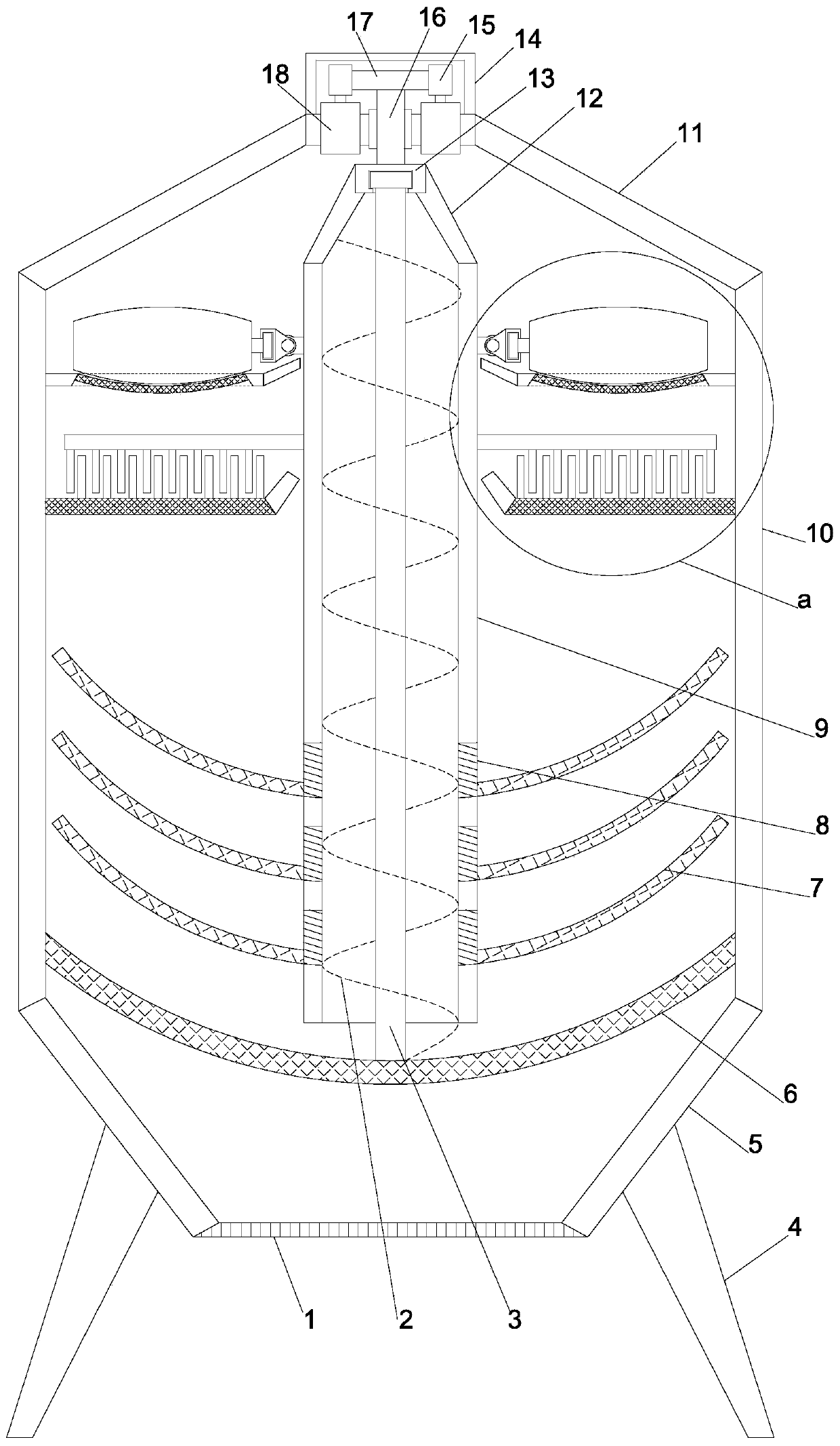

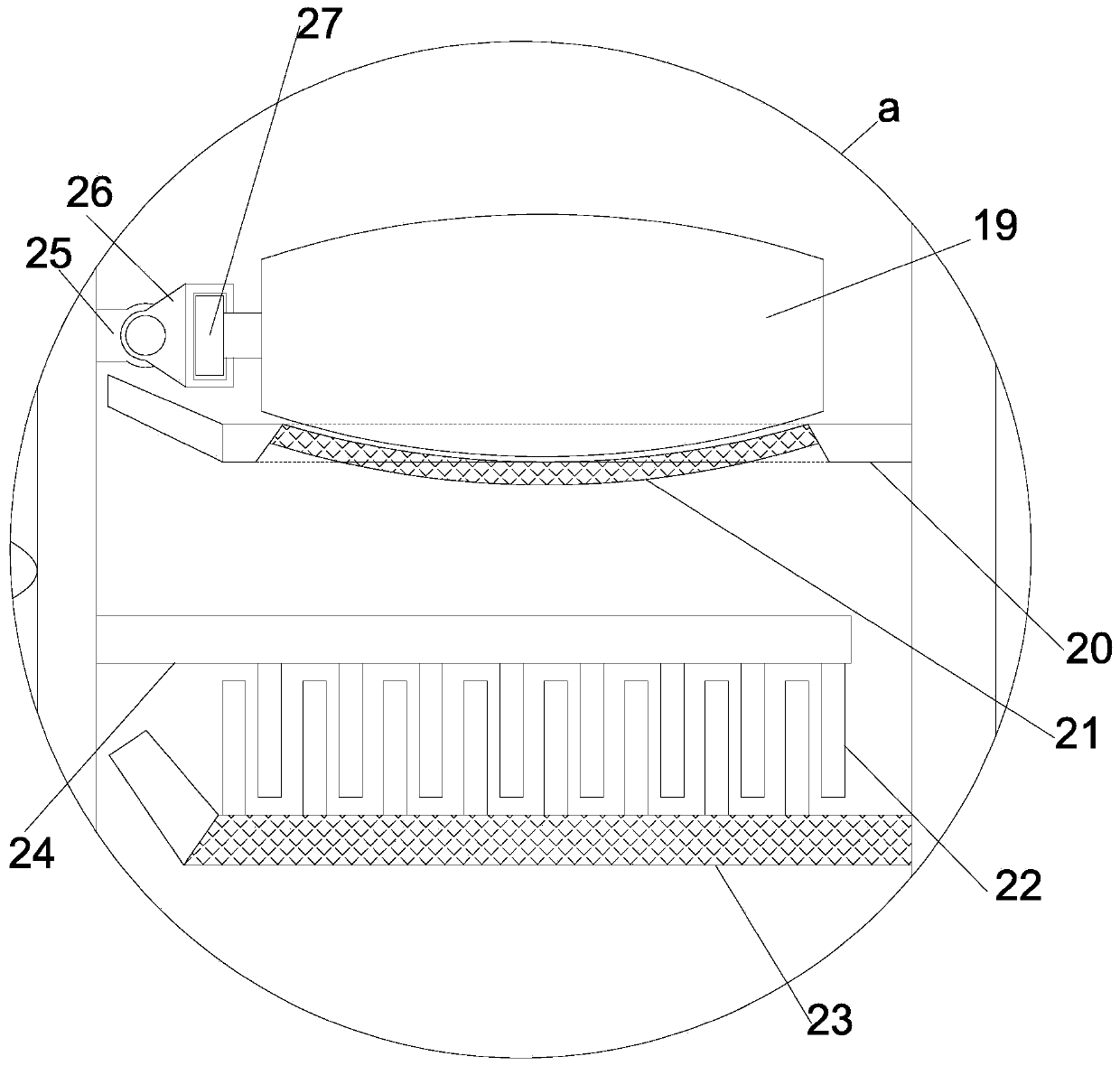

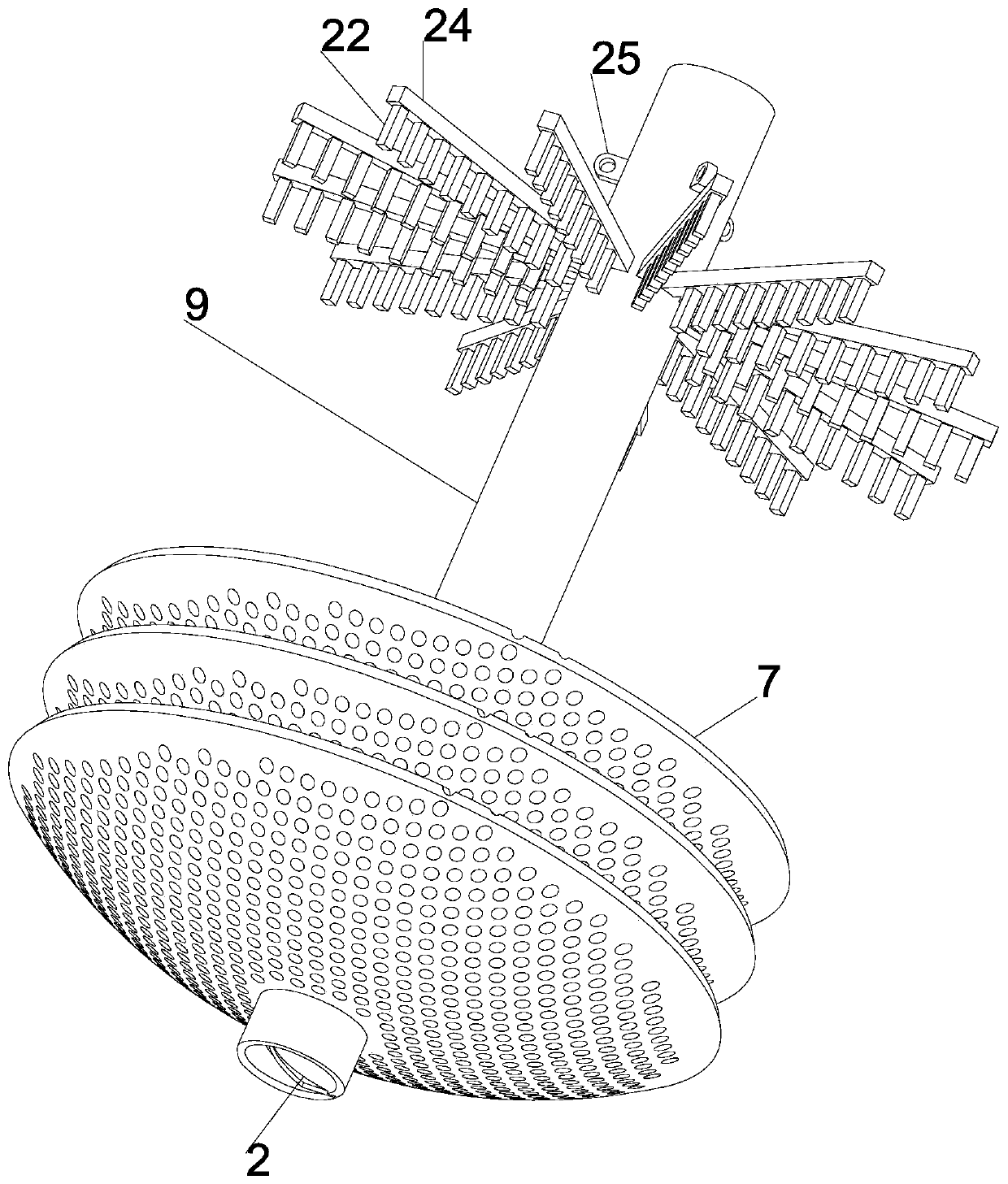

[0021] see Figures 1 to 3 , In the embodiment of the present invention, a multi-stage grain crushing device of circulating lifting and screening type includes a vertically arranged support and installation cylinder 10, and the lower end of the support and installation cylinder 10 is provided with a conical surface guide cylinder 5, and the conical surface guide cylinder 5 A discharge hole 1 is provided at the lower end of the cylinder, and a number of support and installation columns 4 are provided at equal angles on the outer side of the conical surface material guide cylinder 5. A drive installation cover 14 is vertically arranged directly above the support installation cylinder 10. The edge of the drive installation cover 14 A number of feeding installation columns 11 are arranged at equal angles, and the outer ends of the feeding installation columns 11 are all connected with the upper end of the supporting installation cylinder 10. The inner middle position of the support...

Embodiment 2

[0024] On the basis of the first embodiment, through the filtration of multiple sets of annular curved filter screens 7, the grains can be comprehensively screened, and the grains that cannot be screened can be introduced into the rotating lifting drum 9, which significantly improves the quality and efficiency of screening. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com