Ventilation and dust removal equipment for dust explosion prevention in workshop

A dust removal equipment and anti-dust technology, which is applied in the direction of using liquid separating agent, combined device, and dispersed particle separation, etc., can solve the problems of short dust walking path, small contact area between dust and dust removal structure, and single dust removal method, so as to increase walking distance, prevent residual soil, and enhance the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

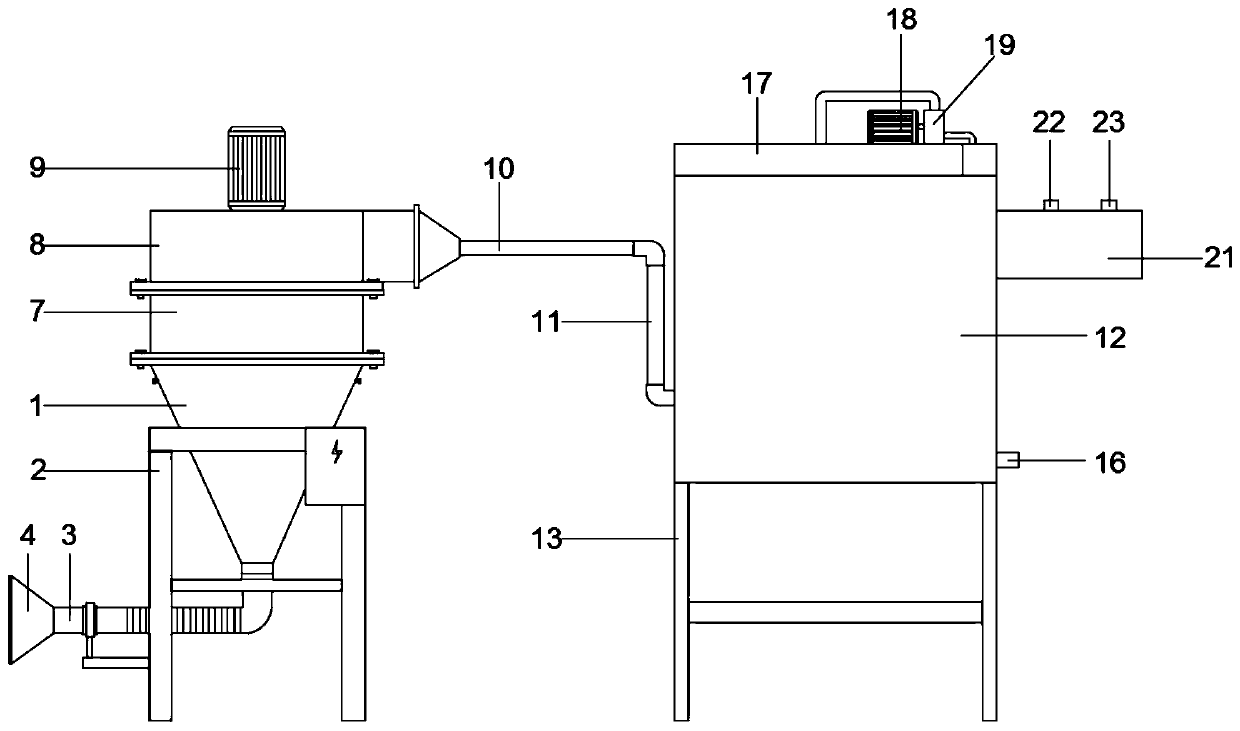

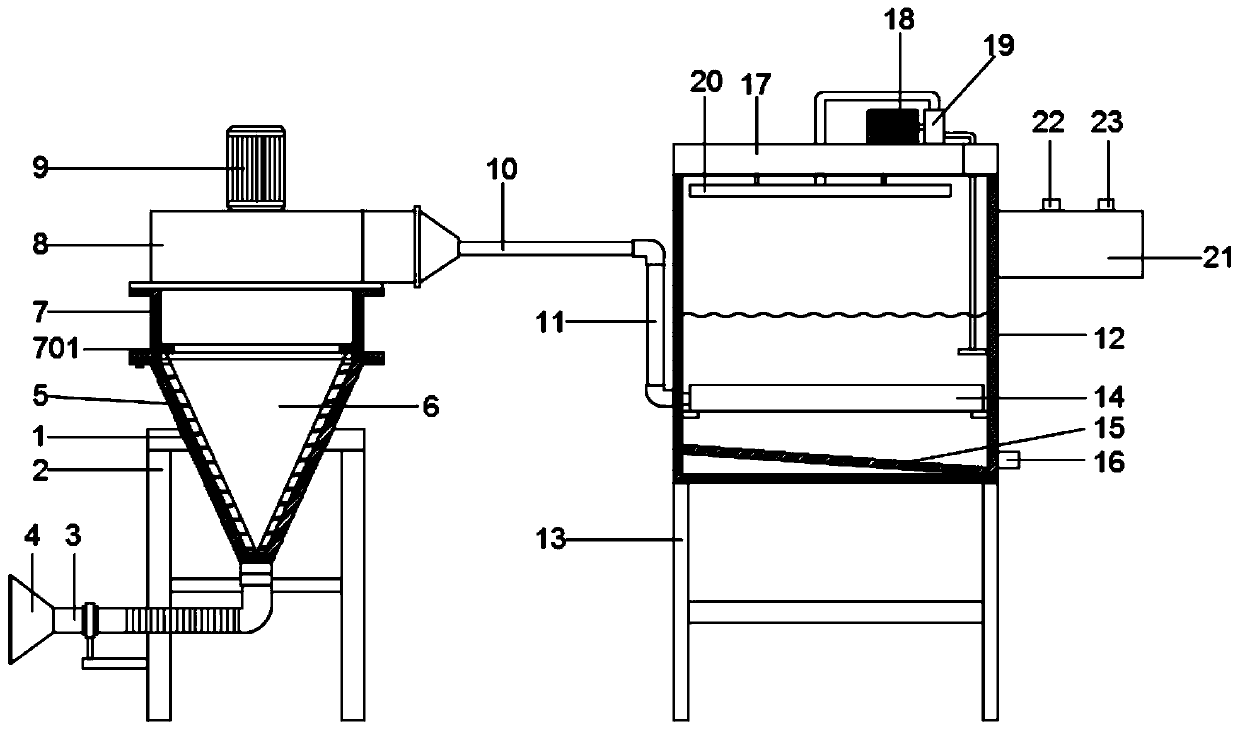

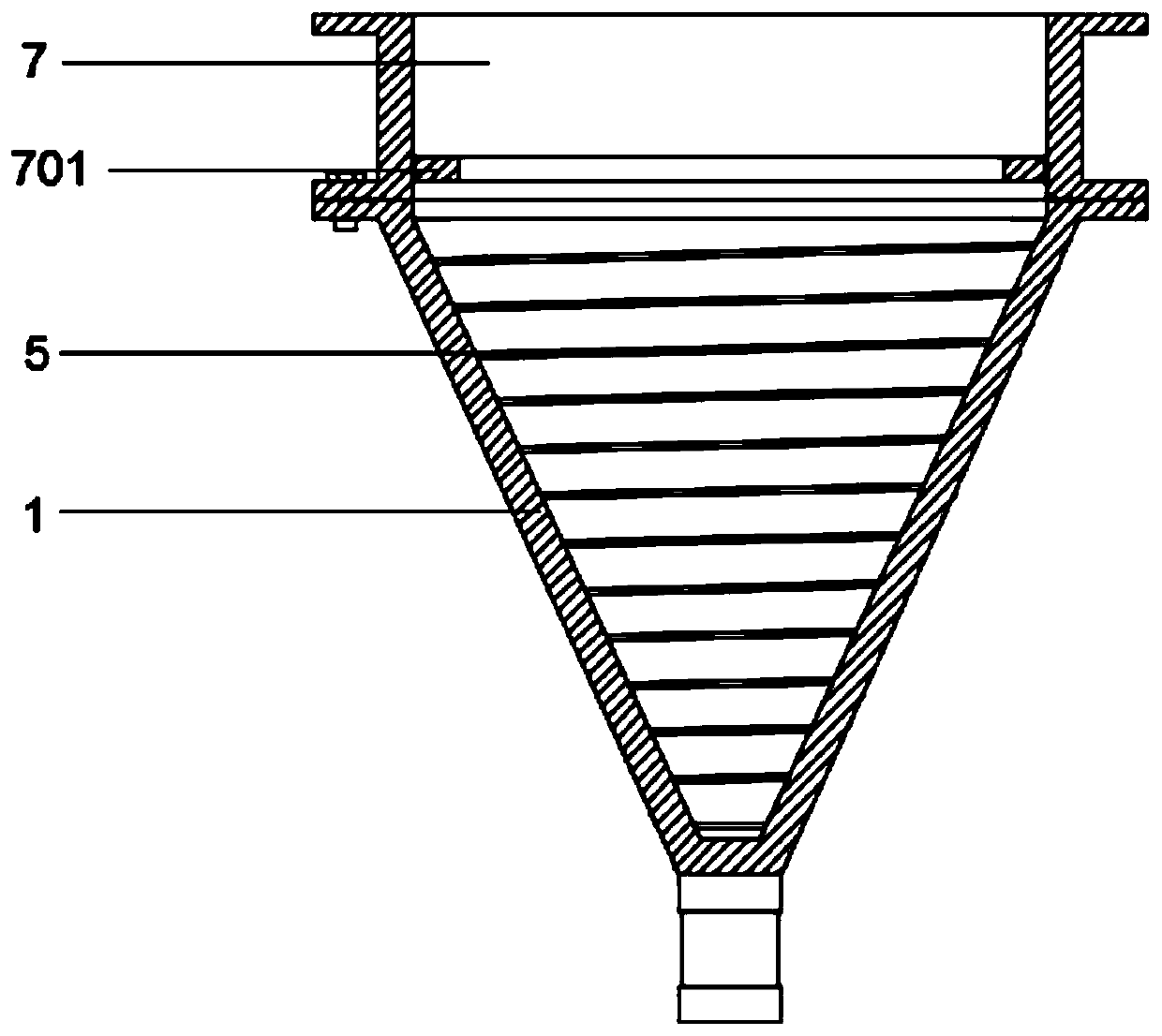

[0037] as attached figure 1 to attach Figure 8 Shown:

[0038]The present invention provides ventilation and dust removal equipment for dust explosion prevention in workshops, including: dust removal cylinder 1, dust removal cylinder support frame 2, air intake pipe 3, air inlet 4, spiral track 5, dust removal structure 6, frame 601, cloth bag 602 , cylindrical tube 7, ring 701, centrifugal fan 8, motor A9, air outlet pipe A10, air outlet pipe B11, square bucket 12, bucket support frame 13, square air outlet 14, circular hole 1401, rectangular plate 15, water outlet pipe 16. Barrel cover 17, motor B18, water pump 19, circular spray port 20, spray hole 2001, square air outlet pipe 21, dry filter box 22 and activated carbon filter box 23; dust removal cylinder 1 is a conical structure, and the outer wall of dust removal cylinder 1 There is a support frame 2 for the dust removal tube which is socketed and welded; the bottom end of the dust removal tube 1 is fixedly connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com