Stator unit, motor, and blower apparatus

A stator unit and stator technology, applied in the field of motors, air supply devices, and stator units, can solve problems such as the influence of rotor rotation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

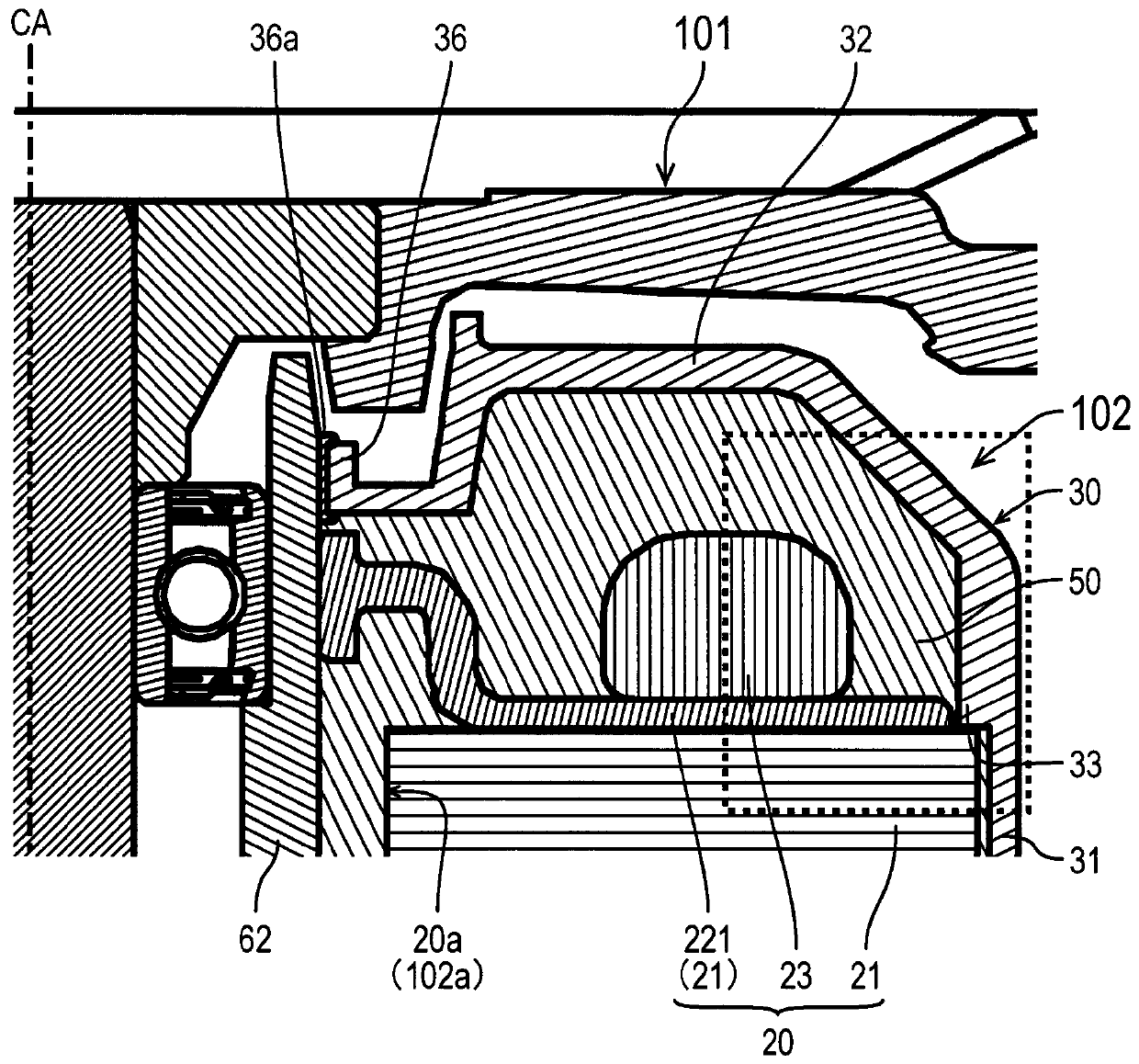

[0023] Hereinafter, exemplary embodiments of the present invention will be described with reference to the drawings.

[0024] In addition, in this specification, the direction parallel to central axis CA in the air blower 300 is called "axial direction." A direction from a cover 70 described later to one axial side of a shaft holder 11 described later in the axial direction is referred to as "axially upward". The direction from the shaft holder 11 to the other side in the axial direction of the cover 70 in the axial direction is referred to as "axially downward". In each constituent element, the axially upper end is referred to as an "axially upper end", and the axial position of the axially upper end is referred to as an "axially upper end". Furthermore, the axially lower end is referred to as an "axially lower end", and the axial position of the axially lower end is referred to as an "axially lower end". Furthermore, among the surfaces of the respective constituent element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com