Gas density relay verification device and verification method thereof

A technology for gas density and calibrating devices, which is applied in measuring devices, circuit breaker testing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

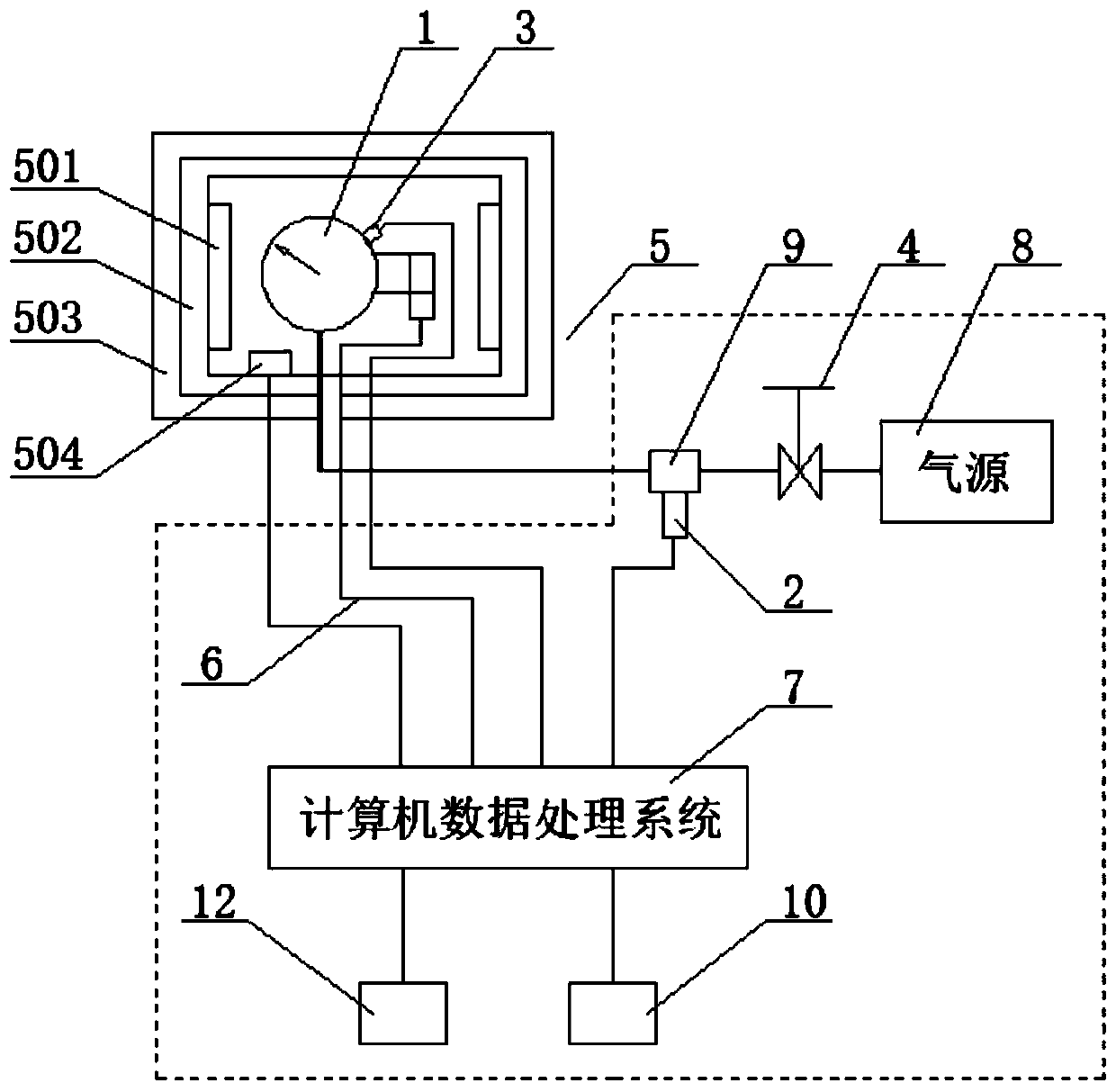

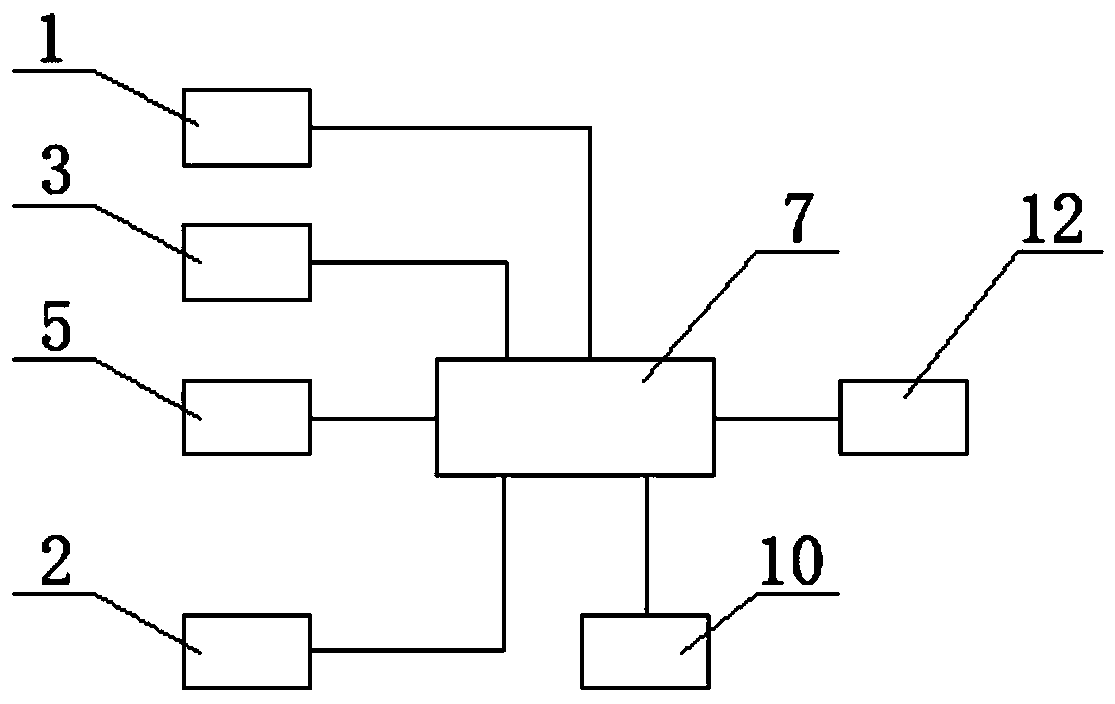

[0163] see figure 1, a gas density relay calibration device, including a temperature adjustment mechanism 5, at least one pressure sensor 2, at least one temperature sensor 3, valve 4, contact signal sampling unit 6, a computer data processing system 7, gas supply mechanism 8 , multi-way joint 9, a display screen 10 and operation keyboard 12. Pressure sensor 2, valve 4, computer data processing system 7, air supply mechanism 8, multi-way joint 9, display screen 10 and operation keyboard 12 are arranged in a box or casing. Wherein, the gas source supply mechanism 8 can store gas for calibration, the gas source supply mechanism 8 is connected with the multi-way joint 9 through the valve 4 , and the pressure sensor 2 is sealed and fixed on the multi-way joint 9 . The multi-way joint 9 is provided with an interface, which can be connected with the gas density relay 1 on the gas path. The temperature adjustment mechanism 5 is an adjustable temperature adjustment mechanism; during...

Embodiment 2

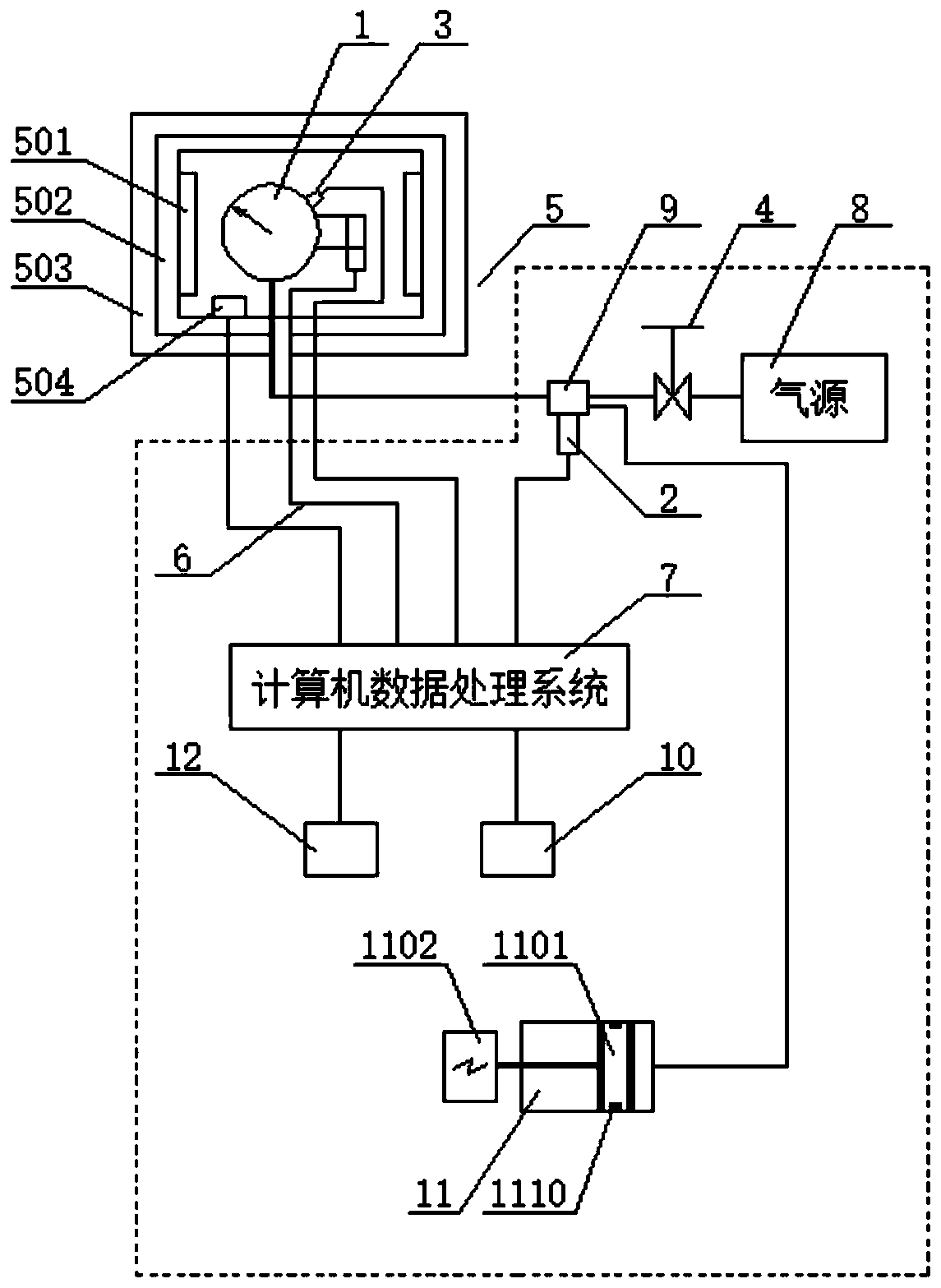

[0169] see image 3 , a gas density relay calibration device according to Embodiment 2 of the present invention, comprising a temperature adjustment mechanism 5, at least one pressure sensor 2, at least one temperature sensor 3, a valve 4, a contact signal sampling unit 6, and a computer data processing system 7 , Air source providing mechanism 8, multi-way connector 9, a display screen 10 and operation keyboard 12, pressure regulating mechanism 11. Different from the first embodiment, this embodiment also includes a pressure regulating mechanism 11 . The pressure regulating mechanism 11 includes a pressure regulating cylinder 1104, a piston 1101, a regulating rod 1103, and a hand wheel or a driving mechanism 1102. Move to realize the regulation of the air source pressure in the pressure regulating cylinder 1104.

[0170] At the substation site, during calibration, the temperature adjustment mechanism 5 is set opposite to the gas density relay 1; the contact signal sampling ...

Embodiment 3

[0174] see Figure 4 , Figure 4 It is a schematic diagram of an online calibration device for a gas density relay according to Embodiment 3 of the present invention. Specifically: the gas density relay 1 is installed on the electrical equipment 13 through the multi-way joint 9 , and the gas supply joint 14 is arranged on the multi-way joint 9 . The temperature adjustment mechanism 5 is arranged opposite to the gas density relay 1, and the temperature adjustment mechanism 5, at least one pressure sensor 2, at least one temperature sensor 3, contact signal sampling unit 6, and a computer data processing system 7 are fixed on the gas density relay 1; Wherein, the contact signal sampling unit 6 is connected with the gas density relay 1, specifically, the contact signal sampling unit is connected with the contacts of the gas density relay 1; the pressure sensor 2 is connected with the gas density relay 1 on the gas circuit.

[0175] When in normal working condition, the gas dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com