Detector for detecting load bearing capability of bearing of steering gear

A load-bearing and detection device technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as wear, deformation and lack of steering gear bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

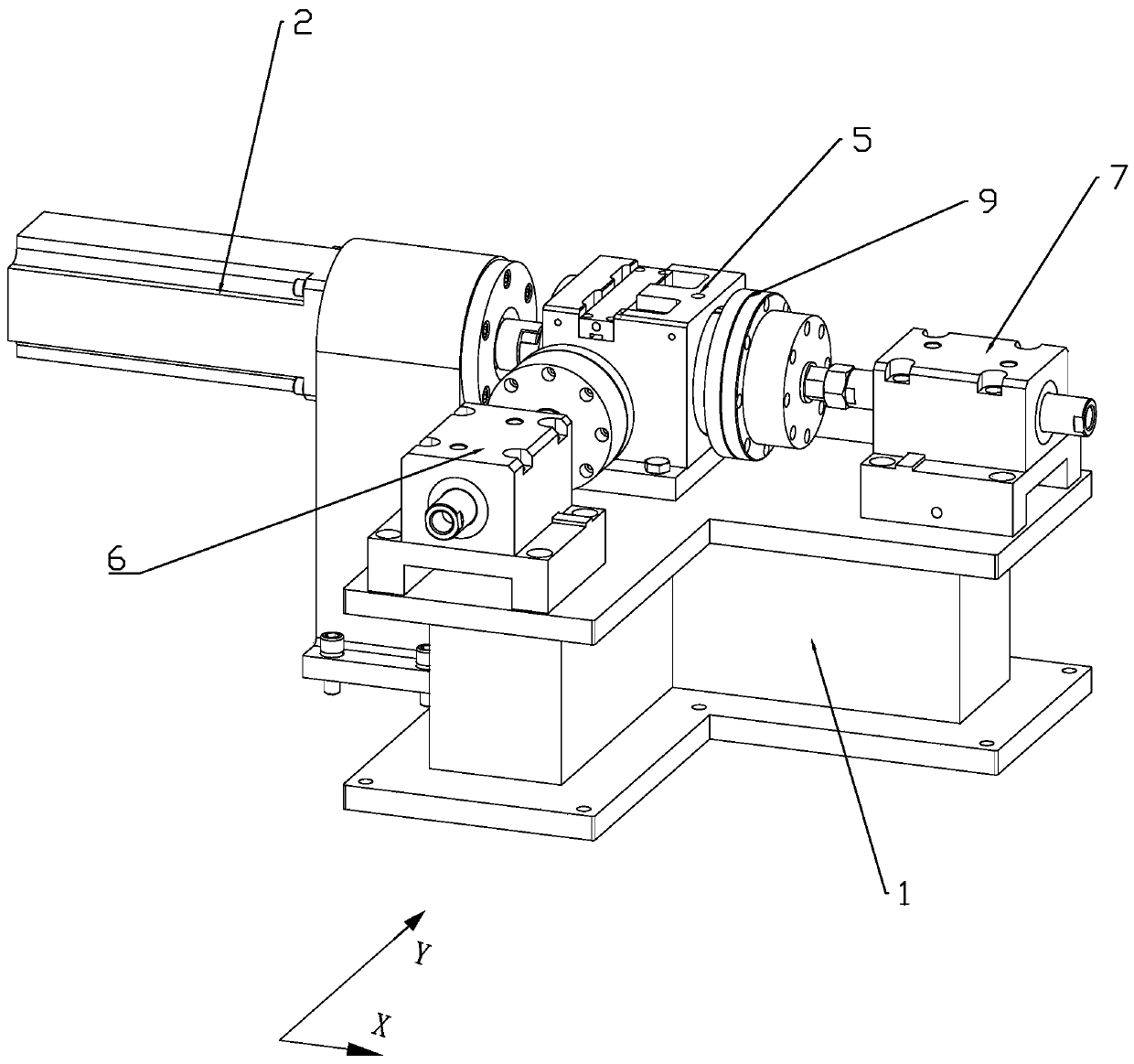

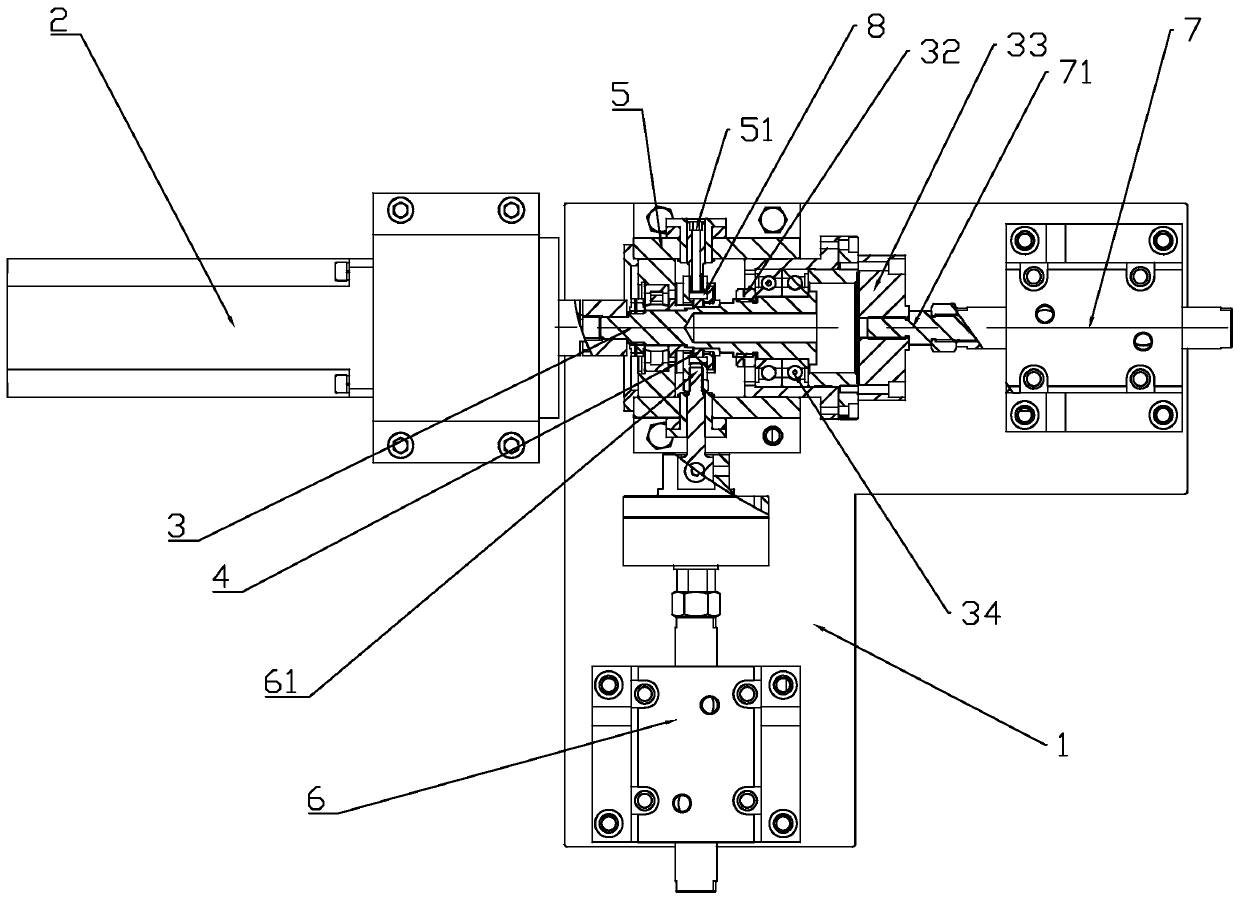

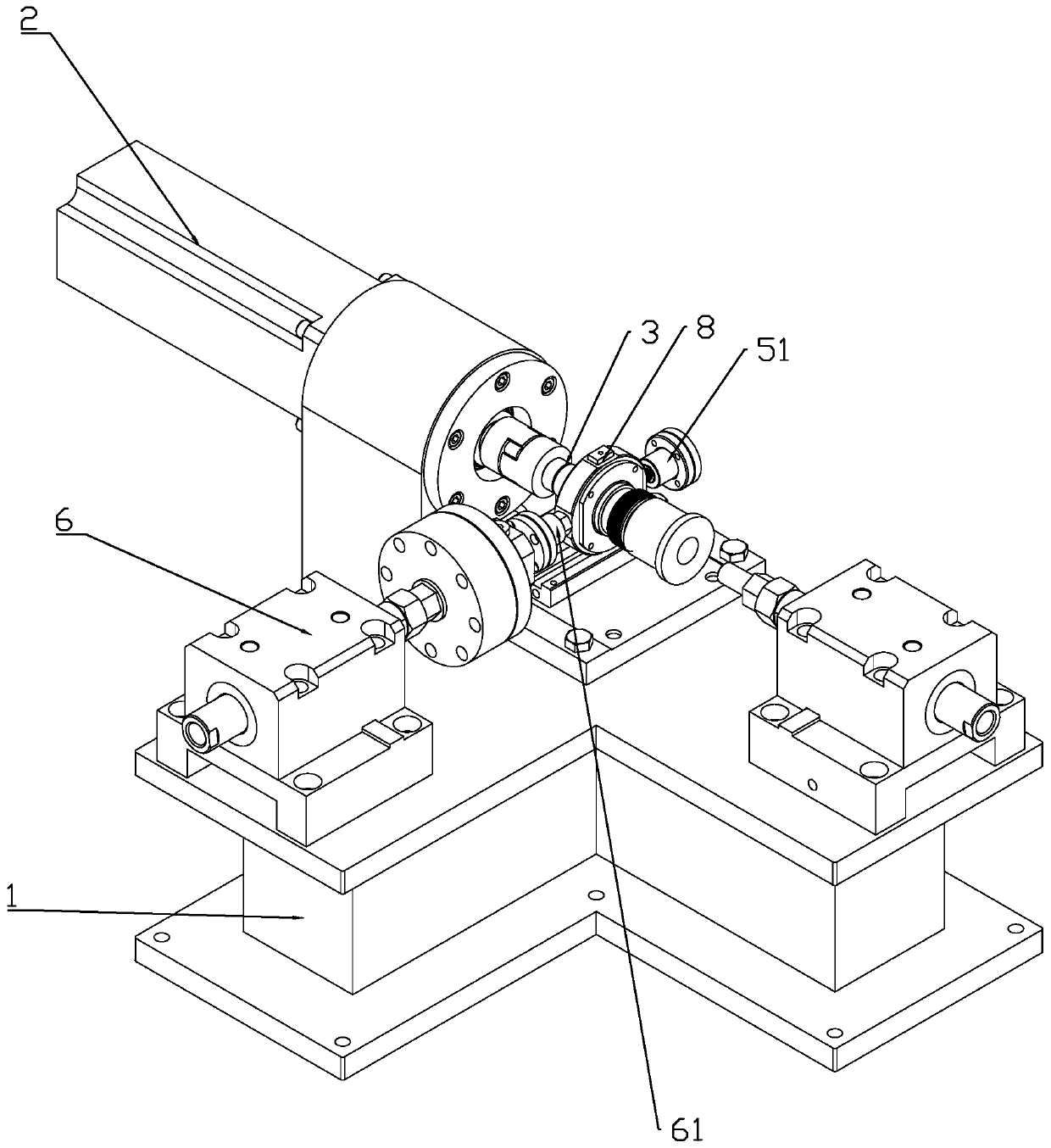

[0023] figure 1 The X-axis direction is the axial direction of the steering gear bearing 4, and the Y-axis direction is the radial direction of the steering gear bearing 4.

[0024] Depend on Figure 1 to Figure 7 It can be seen that the present invention discloses a detection device for detecting the bearing capacity of a steering gear bearing, which includes a machine base 1 and a drive motor 2, the machine base 1 is provided with a rotating main shaft 3, and the rotating main shaft 3 and the driving motor The output end of 2 is connected by transmission. The rotating main shaft 3 is provided with a fixed mounting seat 5 for installing the steering gear bearing 4. The driving cylinder 6 is arranged on the base 1. The output end of the driving cylinder 6 is along the direction of the rotating main shaft 3. Set radially, the output end of the driving cylinder 6 is connected with the fixed mounting seat 5 and set to realize the radial force of the steering gear bearing 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com