Prefabricated low-mass, heat-preservation and noise-reduction wallboard and preparation method thereof

A technology of prefabricated assembly and noise reduction wall, applied in building components, climate change adaptation, construction, etc., can solve the problems of unsatisfactory thermal insulation and noise reduction effect, high construction period and cost, unsatisfactory strength, etc., and achieves remarkable noise reduction effect. , the effect of shortened maintenance time and convenient pre-embedded pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

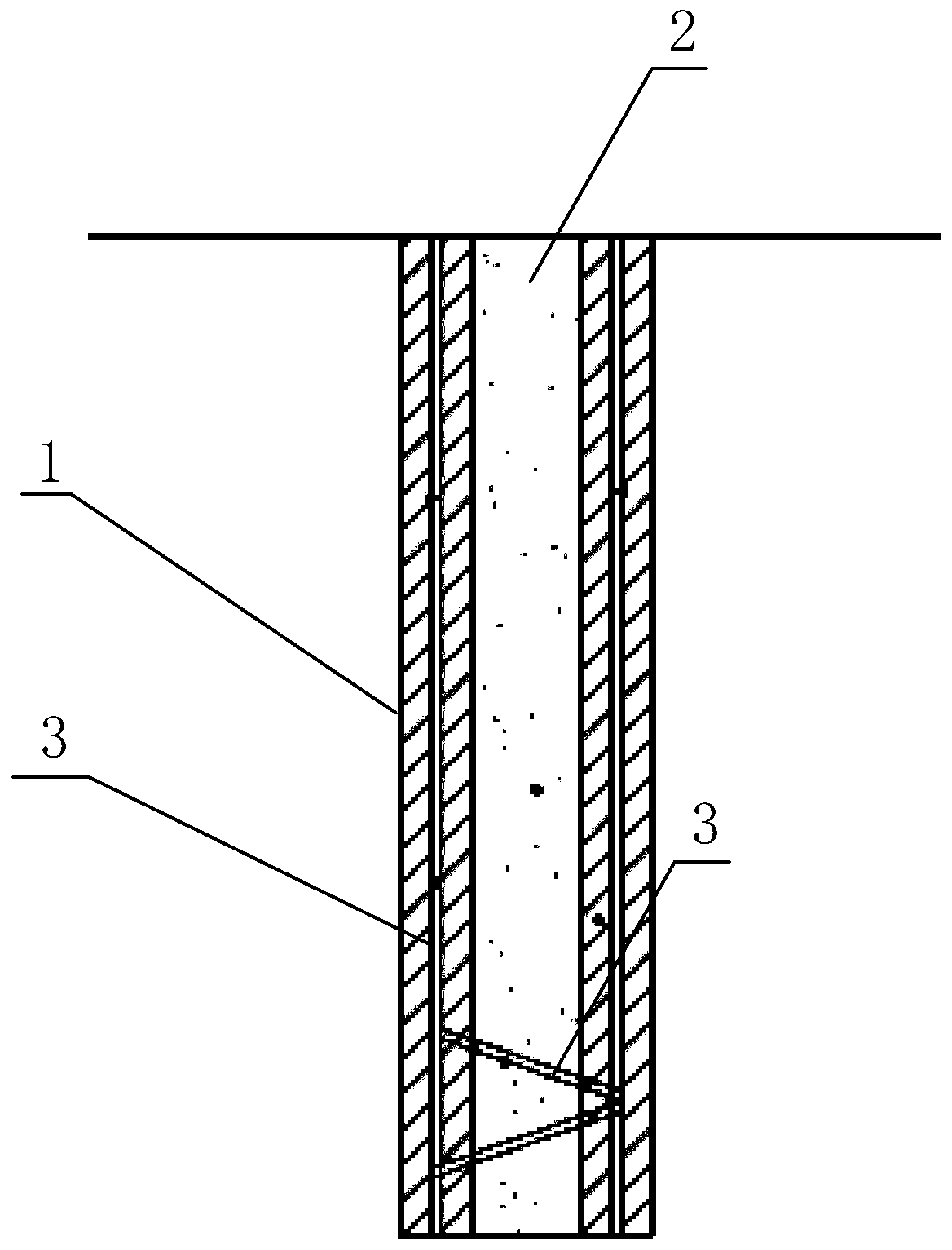

[0045] The preparation method of prefabricated lightweight thermal insulation and noise reduction wallboard includes the following steps:

[0046] 1) First make a reinforced concrete layer, and pre-bury the steel bars for connecting the middle layer and the other outer layer before solidification, so that the steel bars penetrate the surface of the reinforced concrete layer.

[0047] 2) After being solidified, the whole is turned over, butt against another newly poured reinforced concrete layer, so that the steel bars are inserted into another reinforced concrete layer to form a two-layer hollow body.

[0048] 3) After solidification, erect the hollow body vertically, install the template at the bottom, and pour the pouring material for the interlayer of the porous mixture;

[0049] 4) After curing for 20-30 hours in a constant temperature and humidity environment (temperature 40-80°C, humidity RH95% or more), the finished product is obtained.

Embodiment 1

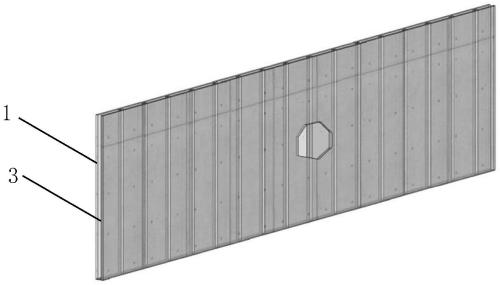

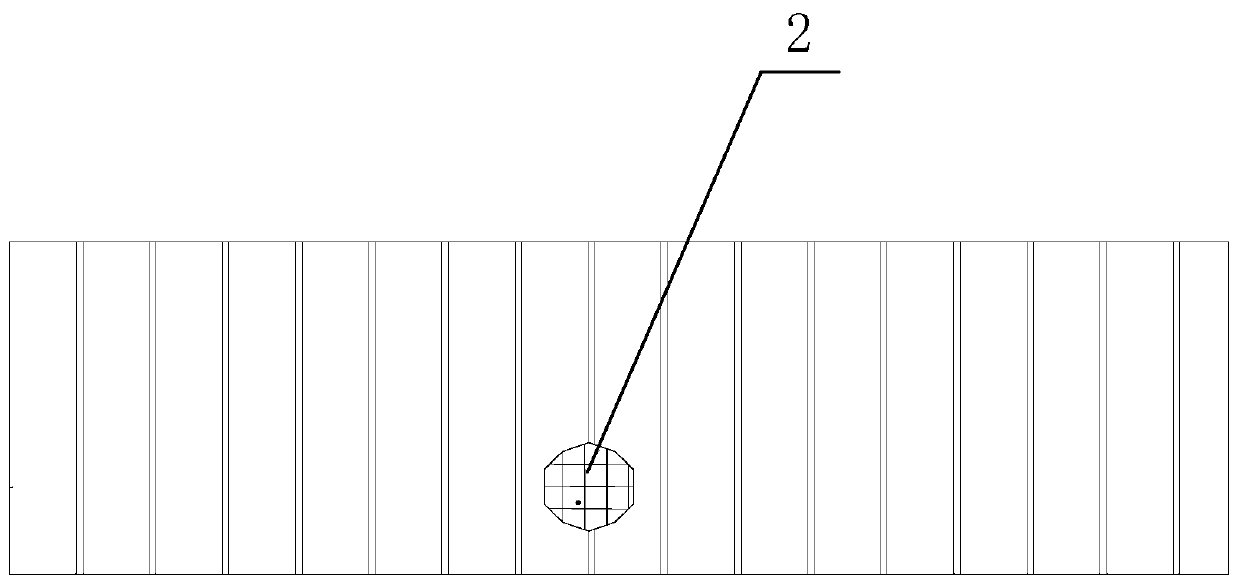

[0051] A prefabricated lightweight heat-insulating and noise-reducing wallboard includes a three-layer structure: two outer layers are reinforced concrete layers, and the middle layer is a porous mixed interlayer; the wallboard is provided with three-layer steel bars; the porous The mixed interlayer contains bamboo and wood mixed fibers. The thickness ratio of the three-layer structure of the outer layer, the middle layer, and the outer layer is 1:1:1 (total thickness of 16 cm).

[0052] Among them, the castable of the interlayer of the porous mixture includes the following components in terms of mass percentage:

[0053] Portland cement 17.58 parts,

[0054] 41.42 parts of bamboo and wood mixed fiber (mass ratio 0.815:0.185),

[0055] 39.1 parts of sand,

[0056] 8.15 parts of water,

[0057] Modified admixture (mixing of early-strength water reducing agent and viscosity modifier) 0.15 parts.

[0058] The preparation method of prefabricated lightweight thermal insulation and noise re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com