Concealed concrete filling elevation controller and operating method thereof

A technology of elevation control and concrete, which is applied in the direction of instruments, infrastructure engineering, electric/magnetic thickness measurement, etc., can solve the problems of delaying construction progress, waste of concrete, low control accuracy, etc., to improve control accuracy, reduce construction costs, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0062] As an embodiment, the underwater airtight probe further includes a sealed shell, and a rubber ring 2-4 is sheathed on the rotating shaft of the motor 2-3, and the rubber ring 2-4 is pressed between the motor and the sealed shell.

[0063] In this embodiment, the rubber ring is pressed between the motor and the sealing shell, thereby improving the waterproofness of the underwater airtight probe.

[0064] As an embodiment, the sealed case also includes a sealed back cover 2-2, the sealed back cover 2-2 is provided with a wire serial port 2-1, and one end of the wire serial port 2-1 is connected to the waterproof wire 1-2, The other end is connected to the positive and negative terminals of the motor.

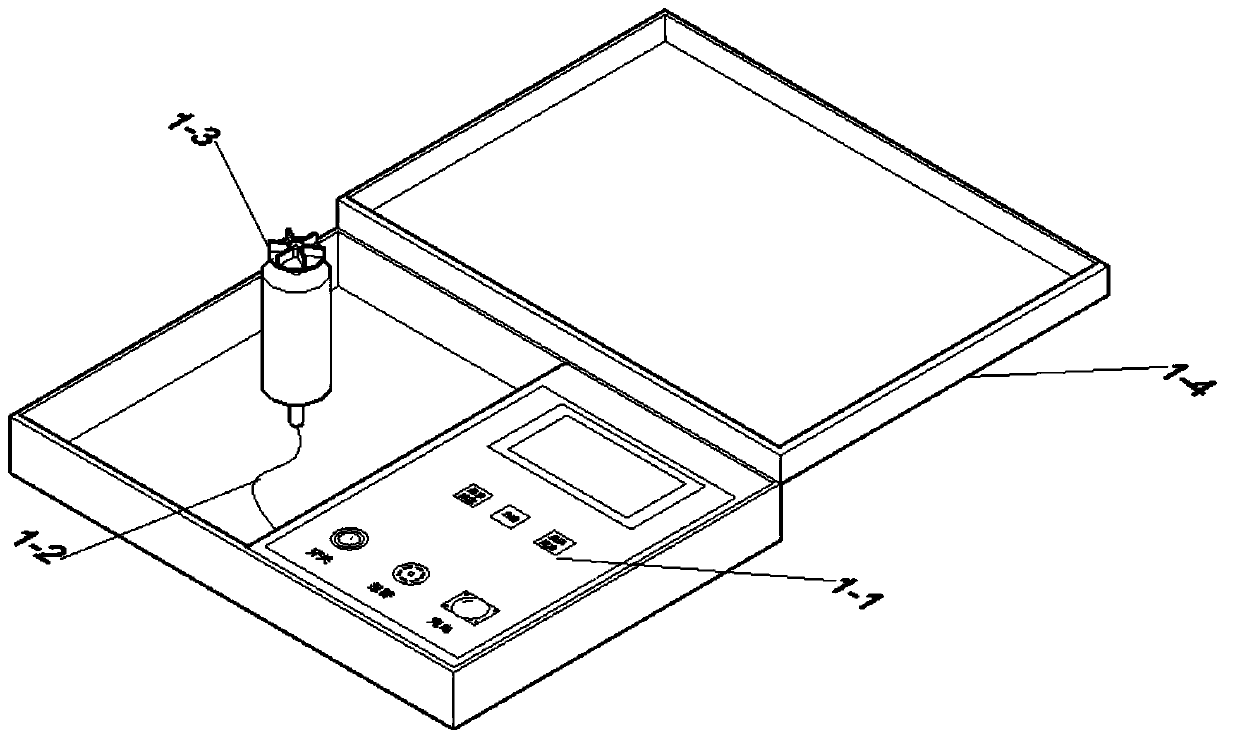

[0065] In a specific implementation, the concealed concrete pouring height control instrument also includes a box body 1-4, and when the concealed concrete pouring height controller is in a non-working state, the concealed monitor and the underwater airtight probe are both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com