Modified vanadium silicon molecular sieve, its preparation method and application, and sulfide oxidation method

A silicon molecular sieve and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of limited application and poor catalytic performance, and achieve the effect of good catalytic effect and modulation selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

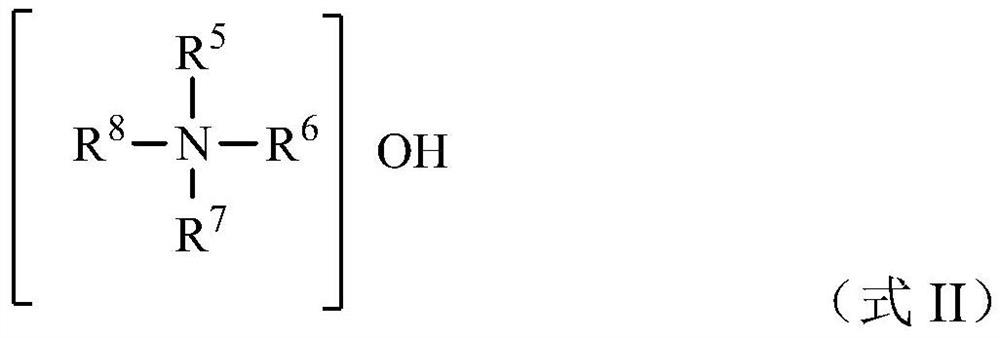

[0030] According to a preferred embodiment of the present invention, B=i×nV, wherein, 0960 / I 800 The ratio B is positively correlated.

[0031] According to the molecular sieve of the present invention, preferably the molecular sieve satisfies T w / T k =D, 0.2w is the pore volume of the molecular sieve, T k is the total pore volume of the molecular sieve.

[0032] According to the molecular sieve of the present invention, preferably, the molar ratio of silicon element: vanadium element is 100: (0.1-10), more preferably silicon element: the molar ratio of vanadium element is 100: (0.2-5), further preferably silicon element: The molar ratio of the vanadium element is 100:(0.5-4), most preferably 100:(1-4).

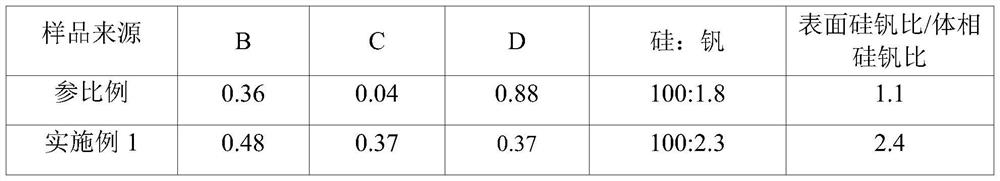

[0033] According to the modified vanadium-silicon molecular sieve of the present invention, preferably, the surface silicon-vanadium ratio of the molecular sieve is not lower than the bulk silicon-vanadium ratio, and the silicon-vanadium ratio refers to the molar ratio of...

Embodiment 1

[0102] This example illustrates the methods and products provided by the invention.

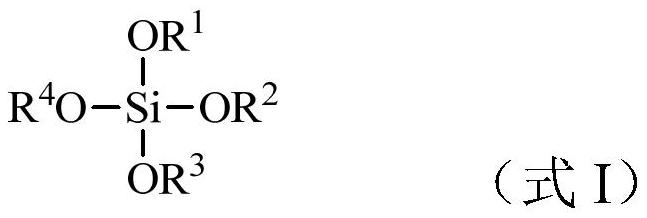

[0103]At normal temperature (20°C, the rest of the comparative examples are the same as the examples) and normal pressure (0.1MPa, the rest of the comparative examples are the same as the examples), first mix the vanadium silicon molecular sieve with 1mol / L aqueous hydrochloric acid for beating, and then mix the mixed slurry in Mix and stir at 80°C for 12 hours; after solid-liquid separation, mix the solid, vanadium source ammonium metavanadate, organosilicon source tetraethyl orthosilicate and sodium hydroxide aqueous solution (pH 12), and treat tetraethyl orthosilicate After hydrolysis (the hydrolysis rate of the organic silicon source is 40%), the mixture is transferred to a stainless steel sealed reactor, and treated at 170° C. for 12 hours, wherein the vanadium silicon molecular sieve: vanadium source: organic silicon source: acid: alkali: the molar ratio of water is 100:0.5:2:10:5:250, ...

Embodiment 2

[0105] This example illustrates the methods and products provided by the invention.

[0106] At normal temperature and pressure, first mix the vanadium silicon molecular sieve with 5mol / L hydrochloric acid solution for beating, then mix and stir the mixed slurry at 60°C for 1 hour; The source methyl orthosilicate is mixed with tetrapropylammonium hydroxide aqueous solution (pH is 10), and after the methyl orthosilicate is hydrolyzed (organosilicon source hydrolysis rate is 50%), the mixture is transferred to a stainless steel sealed reaction kettle, and the Treat at ℃ for 12 hours, wherein, vanadium silicon molecular sieve: vanadium source: organosilicon source: acid: alkali: water molar ratio is 100:1:1:15:15:200, vanadium silicon molecular sieve and organosilicon source are SiO 2 In terms of acid, H + In terms of base, in N. Then the product was recovered according to the method of Example 1 to obtain the modified vanadium silicon molecular sieve S-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com