A surface sprinkler nozzle control box and its installation method

A control box and spray box technology, which is applied in manufacturing tools, printing devices, printing, etc., can solve problems such as long shutdown processing time of on-duty personnel, failure to meet printing requirements, damage to nozzle control boards, etc., to reduce massive consumption and improve The effect of reducing production rhythm and reducing inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

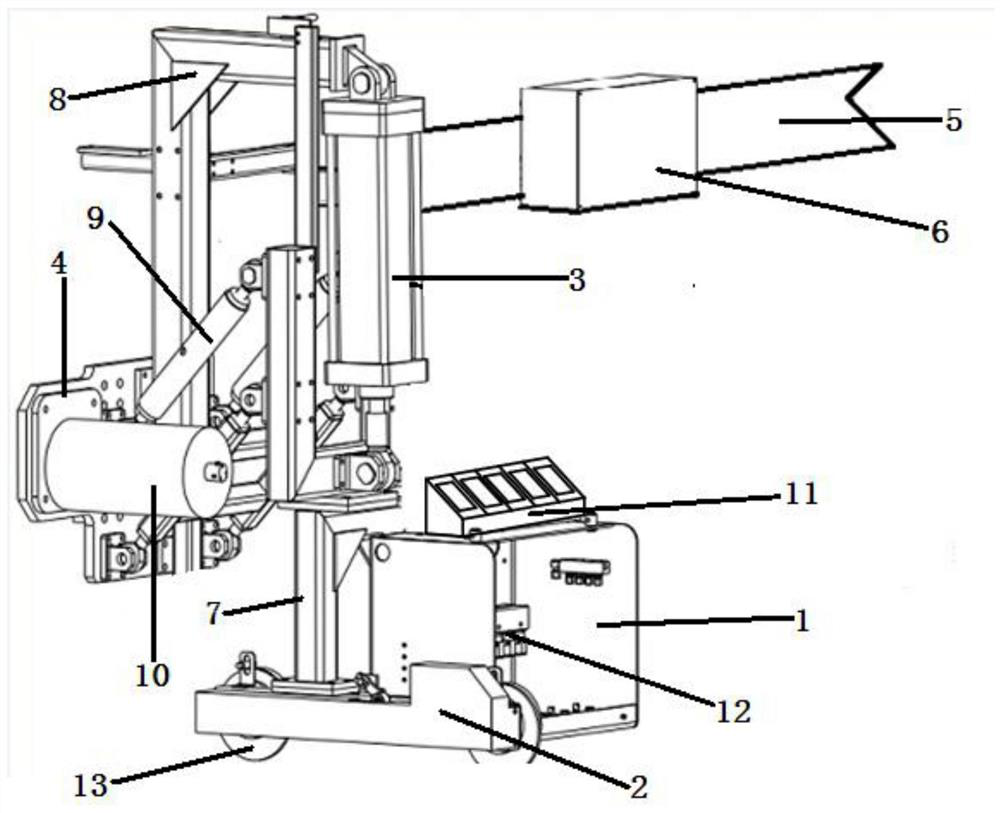

[0017] This embodiment provides a spray head control box for a surface spray machine, including a spray box 1 and a control box assembly. The control box assembly includes a base 2, a spray box lifting cylinder 3, a backplane fixing bracket assembly 4, a fixed beam 5, and a spray head control box. 6. The spray box 1 is fixed on one side of the base 2. The upper surface of the base 2 extends vertically upwards with a support frame 7. The support frame 7 supports the spray box lifting cylinder 3. The top of the spray box lifting cylinder 3 is connected to the bracket 8 through an L shape. Connected with the backplane fixing bracket assembly 4, one side of the L-shaped connecting bracket 8 extends horizontally with a fixed beam 5, and the nozzle control box 6 is installed on the fixed beam 5, and the backplane fixing bracket assembly 4 communicates with the support through the drive cylinder 9. The frame 7 is connected and the back plate fixing bracket assembly 4 extends in the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com