Injection mold and demolding method thereof

An injection mold and mold technology, applied in the field of injection molds and their demolding, can solve problems such as increasing product scrap rate, reducing product production efficiency, and difficulty in picking up products, improving injection molding production efficiency, improving injection molding quality, and reducing production. Effects of fees and post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

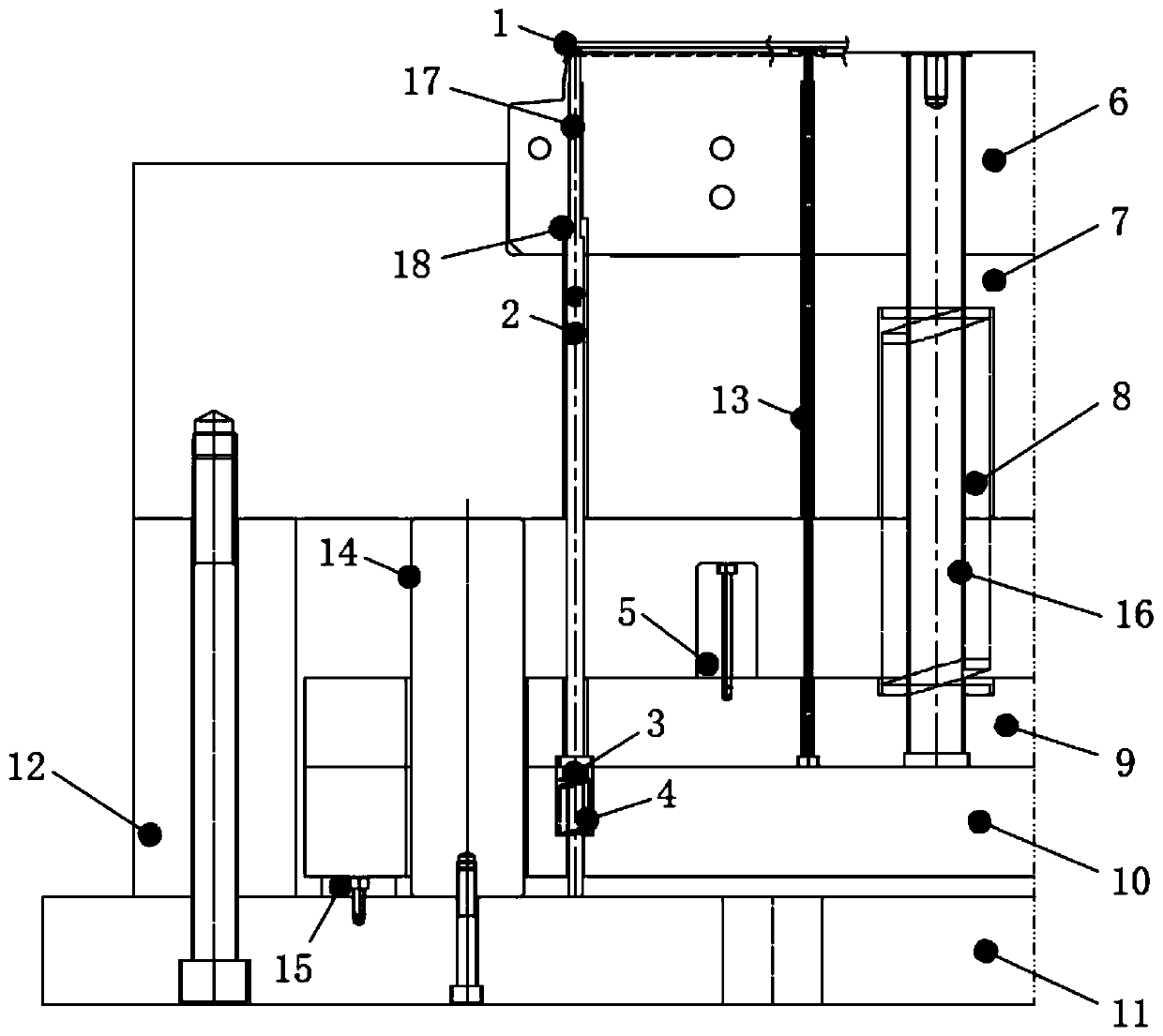

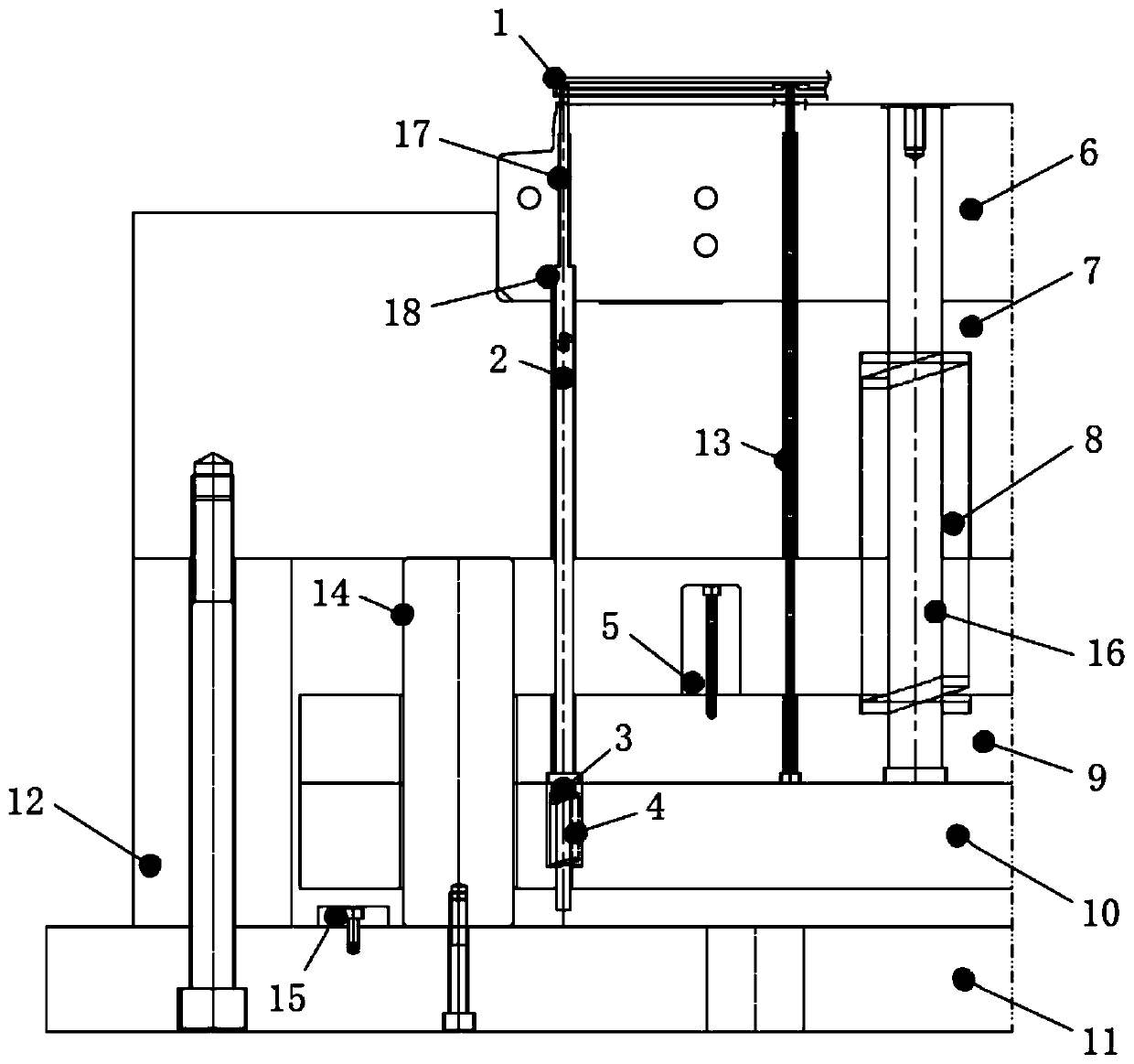

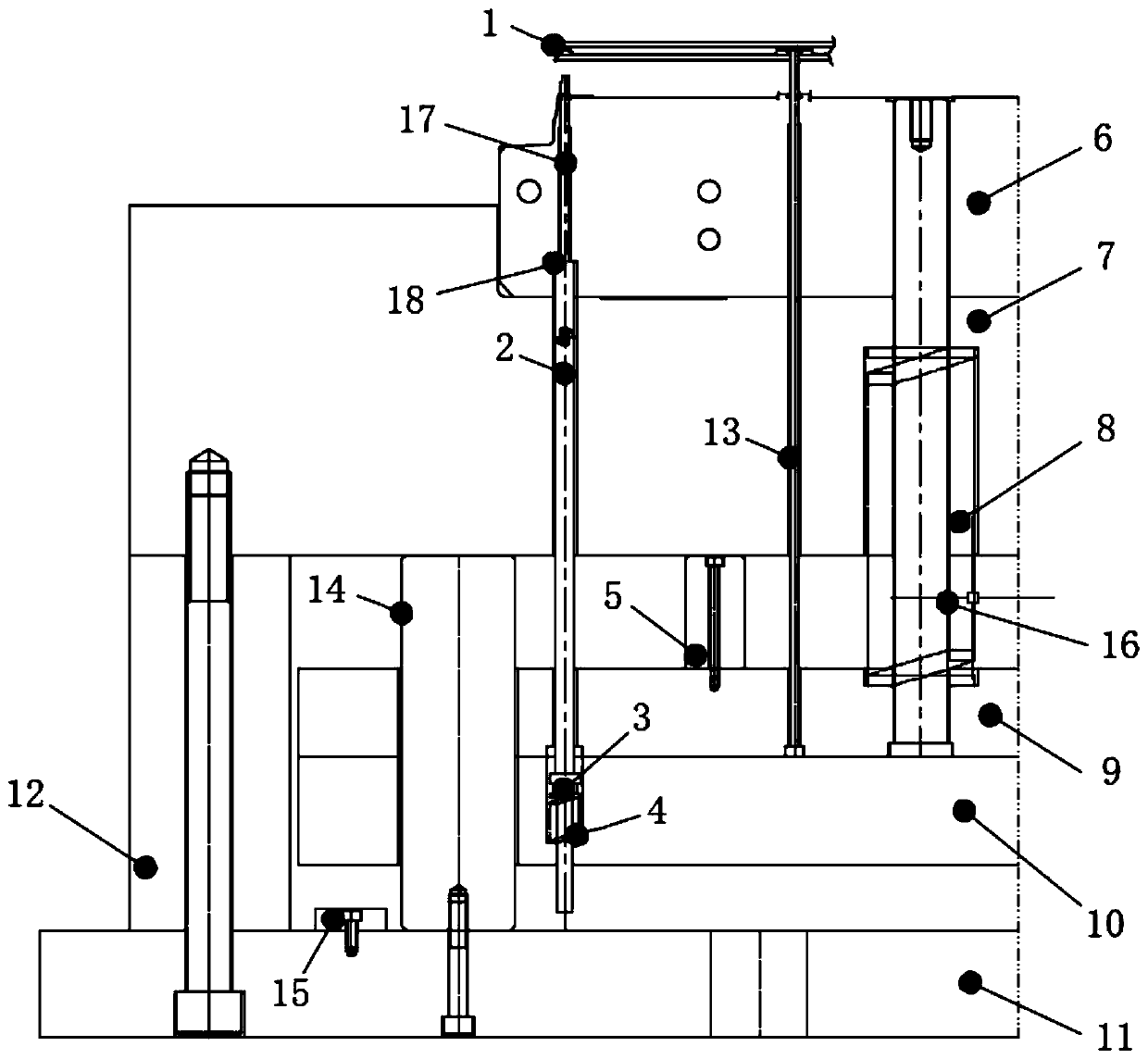

[0031] Embodiment: a kind of injection mold, as Figure 1 to Figure 3 As shown, it includes a seat body, a mold body and an ejection device, the mold body is arranged on the seat body, and the ejection device is used to eject the product out of the mold body. Wherein, the mold body includes an ejection mechanism and a demoulding mechanism, the ejection mechanism is used to eject the narrow side of the product or the surrounding deep ribs, and the demoulding mechanism is used to eject the product out of the mold body, which is convenient for workers to take materials. In this embodiment, the product refers to the injection molded product 1, which is injection molded through the mold body.

[0032] In the prior art, for products with deep ribs, after being ejected, the product will hold tightly to the ejector pin, making it difficult to take out the product. Therefore, in batch injection molding production, the injection molding efficiency is seriously affected, and it is neces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com