Separation release centrifugation gravity compensation device and method

A technology of gravity compensation and separation point, which is used in measurement devices, aerodynamic tests, instruments, etc., to achieve the effects of more equipment, saving test costs, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

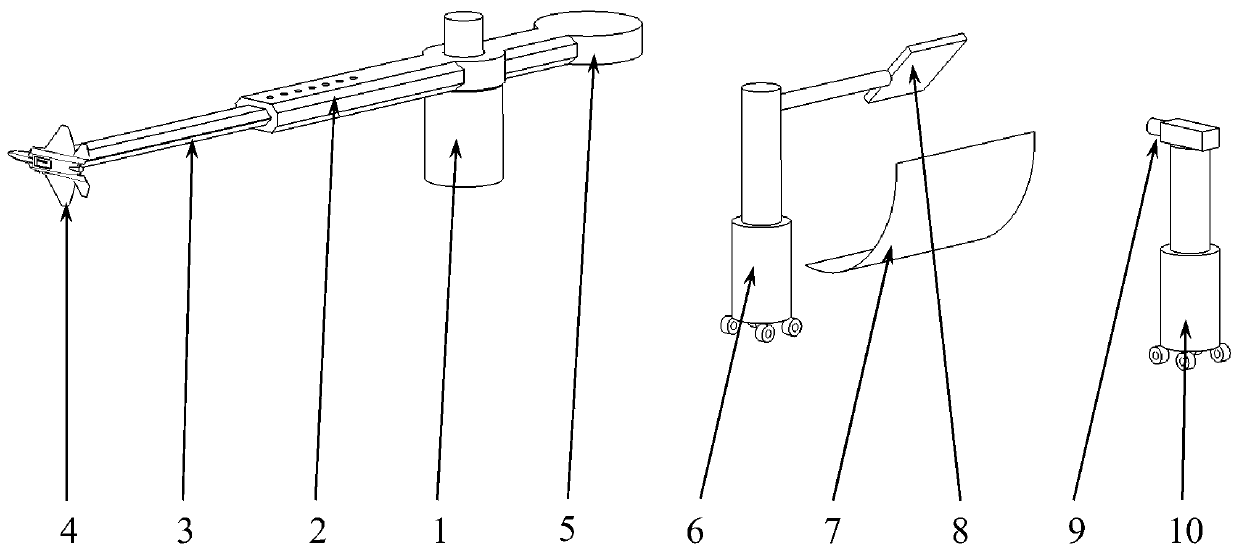

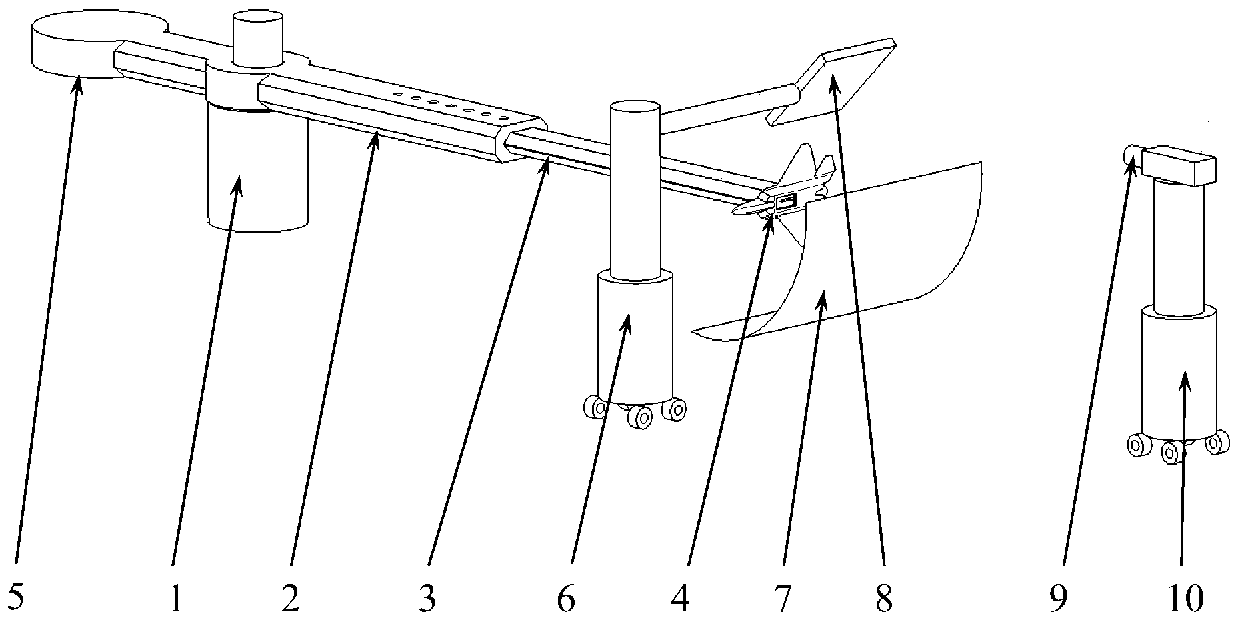

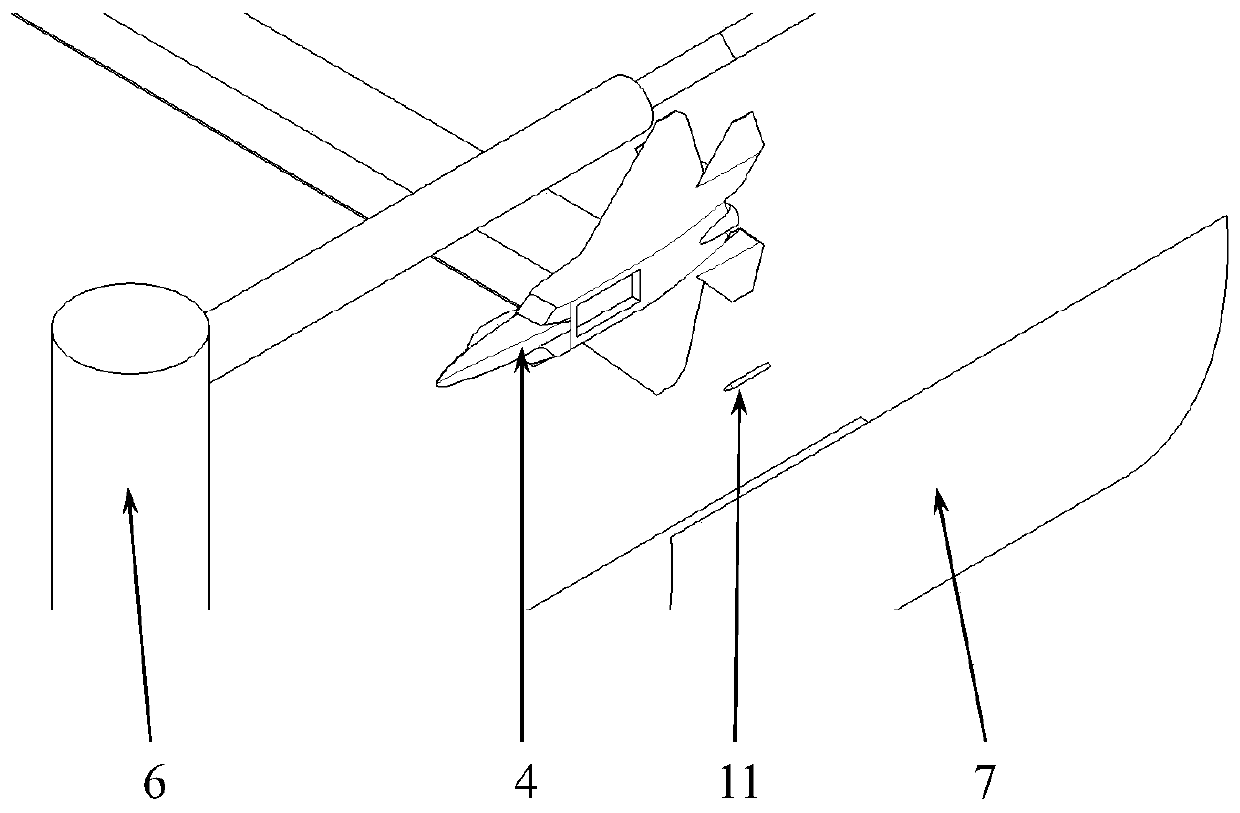

[0032] see Figure 1 ~ Figure 3 As shown, the centrifugal gravity compensation device provided by the present invention includes a rotating table 1, a rotating arm 2, a rotating counterweight 5, and a rotating rod 3; the rotating table 1 is vertically fixed on the ground, and the top of the rotating table 1 is provided with a motor. The rotating arm 2 is perpendicular to and fixed on the motor shaft, and the motor shaft drives the rotating arm 2 to rotate around the rotating table 1; one end of the rotating rod 3 is sleeved in the rotating arm 2, and the other end extends along the rotating arm 2 to the outside of the rotating arm 2, and the end Used to fix the tested carrier model 4, the tested carrier model 4 is equipped with a separation model 11, and the installation attitude of the carrier model 4 can be adjusted to ensure that the separation direction of the sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com