Automatic soil property sampling mechanism

An automatic sampling and soil quality technology, applied in conveyors, conveyor objects, solid separation, etc., can solve the problems of time-consuming and labor-intensive, manual collection, etc., and achieve the effect of high work efficiency and increased collection volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

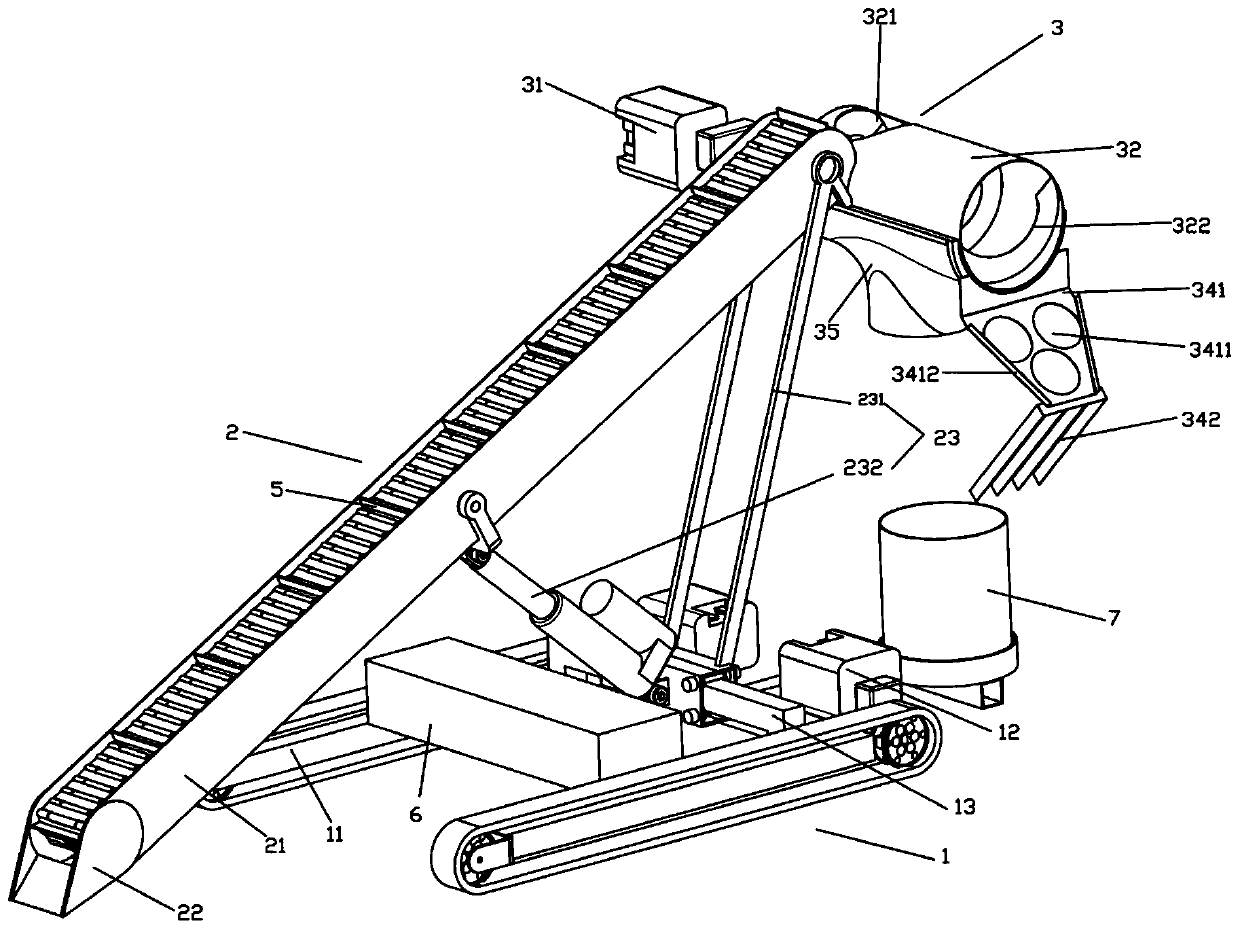

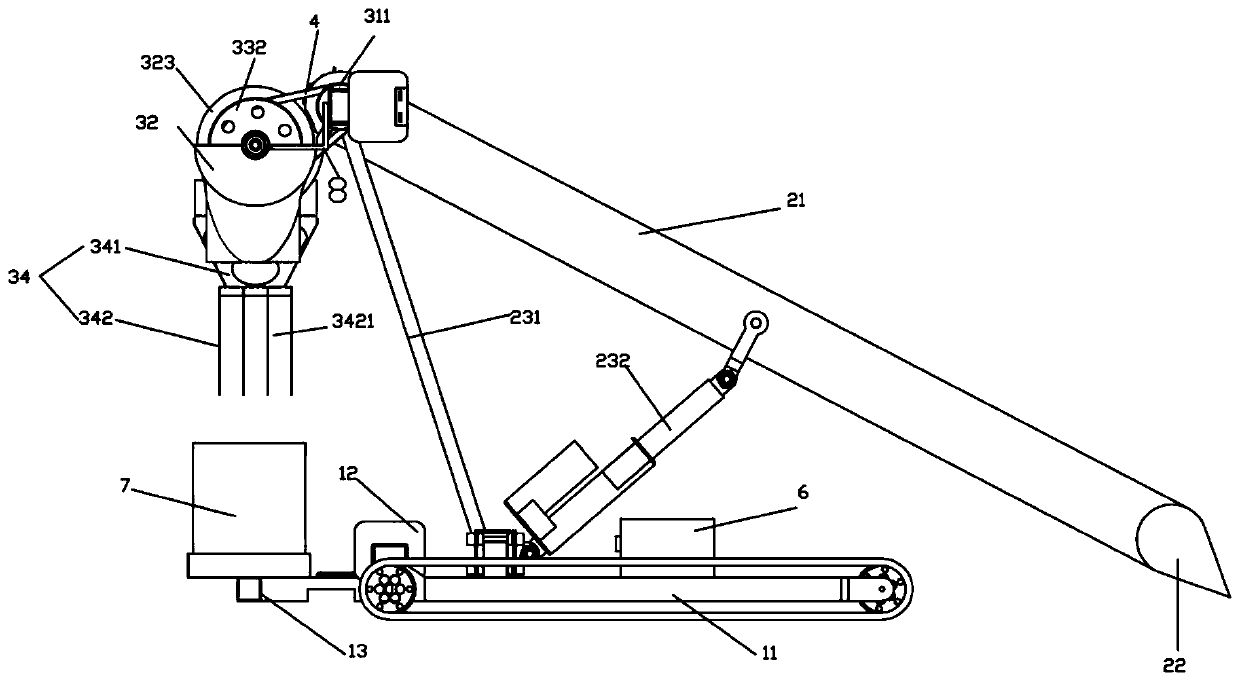

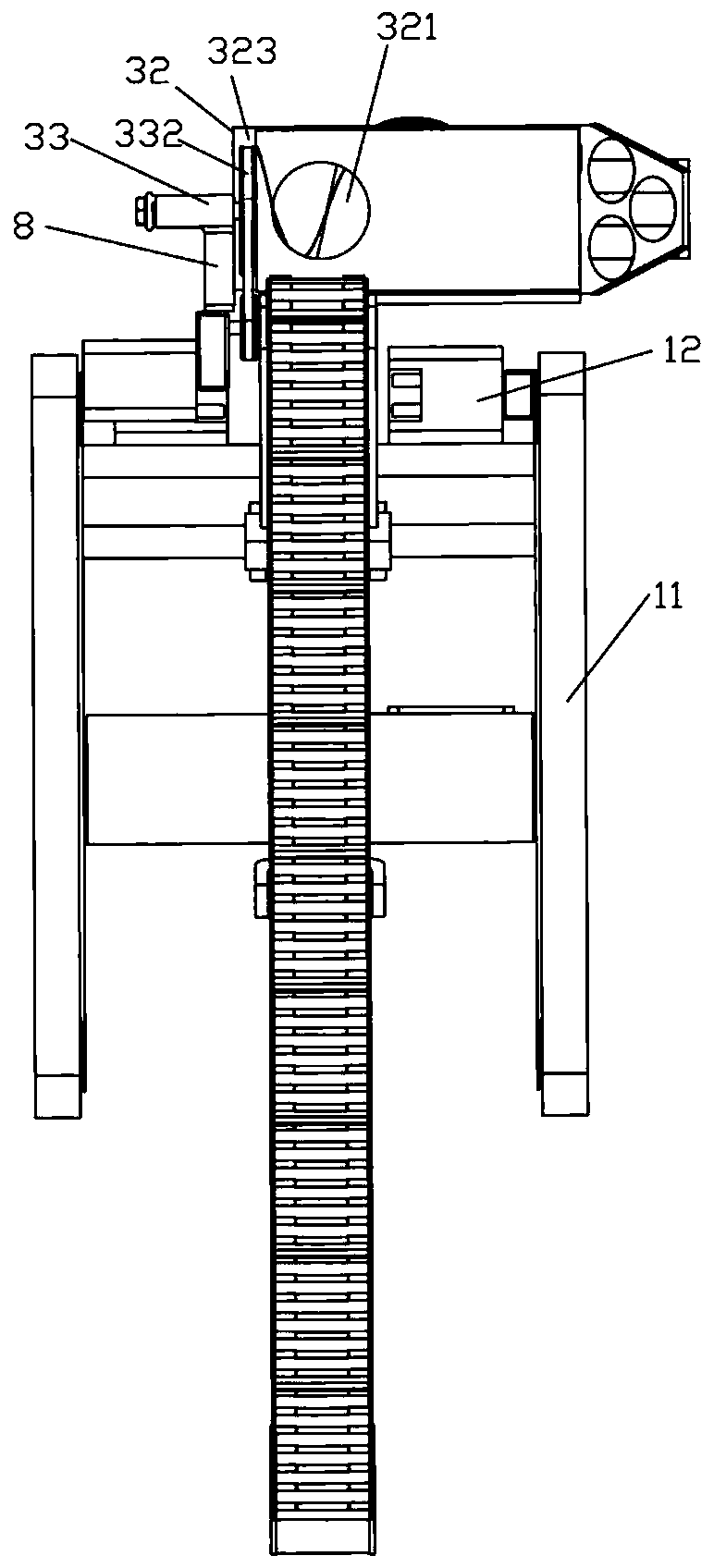

[0031] Such as Figure 1-4 As shown, this embodiment provides an automatic soil sampling mechanism, which includes a crawler belt traveling mechanism 1 , a feeding mechanism 2 and a discharging mechanism 3 . The crawler walking mechanism 1 is supported on the ground and realizes the walking of the entire sampling mechanism. The feeding mechanism 2 takes the material and transports the soil to the discharging mechanism 3. The discharging mechanism filters the soil to collect large particles of soil into the collection box.

[0032] The crawler belt traveling mechanism 1 comprises two crawler belts 11 arranged oppositely and two motors 12 respectively driving the two crawler belts 11 , a mounting seat 13 is fixedly arranged between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com