Full-automatic punching machine of LED lamp tube

An LED lamp, fully automatic technology, applied in metal processing and other directions, can solve the problems of complex structure, unreasonable structural design, low degree of automation, etc., to achieve the effect of scientific and reasonable structure, convenient and fast adjustment, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

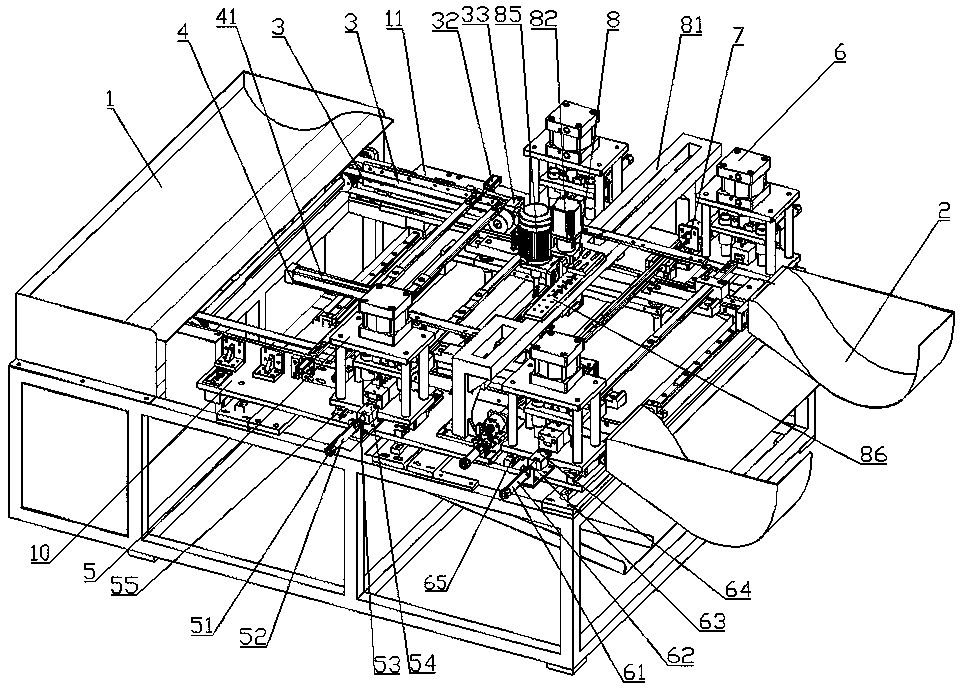

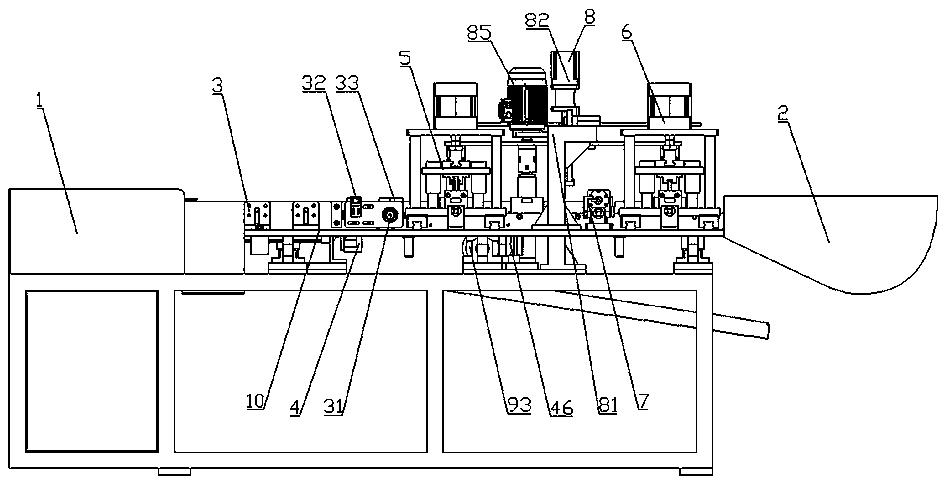

[0026] see Figure 1-7 , a fully automatic punching machine for LED lamp tubes, comprising a machine platform, a feed hopper 1, a feeding assembly 3, a punching assembly, a turning assembly 7 and a discharge hopper 2; the feed hopper 1, the feeding assembly 3, the punching assembly, Both the turnover assembly 7 and the discharge hopper 2 are arranged on the machine platform. A fixed frame 10 and a mobile frame 11 are respectively arranged on both sides of the middle part of the machine, and a transport mechanism 4 is arranged between the fixed frame 10 and the mobile frame 11; the punching assembly includes a first punching die 5 and a second punching die. Hole die 6, a turning assembly 7 is arranged between the first punching die 5 and the second punching die 6, and a pipe middle punching assembly 8 is arranged between the first punching die 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com