Placing frame for automobile body stamping part die

A technology for automobile bodies and stamping parts, which is applied in tool storage devices, workshop equipment, manufacturing tools, etc. It can solve the problems of unfavorable space utilization for placing equipment, and achieve the effects of flexible use, increased placement positions, and increased spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

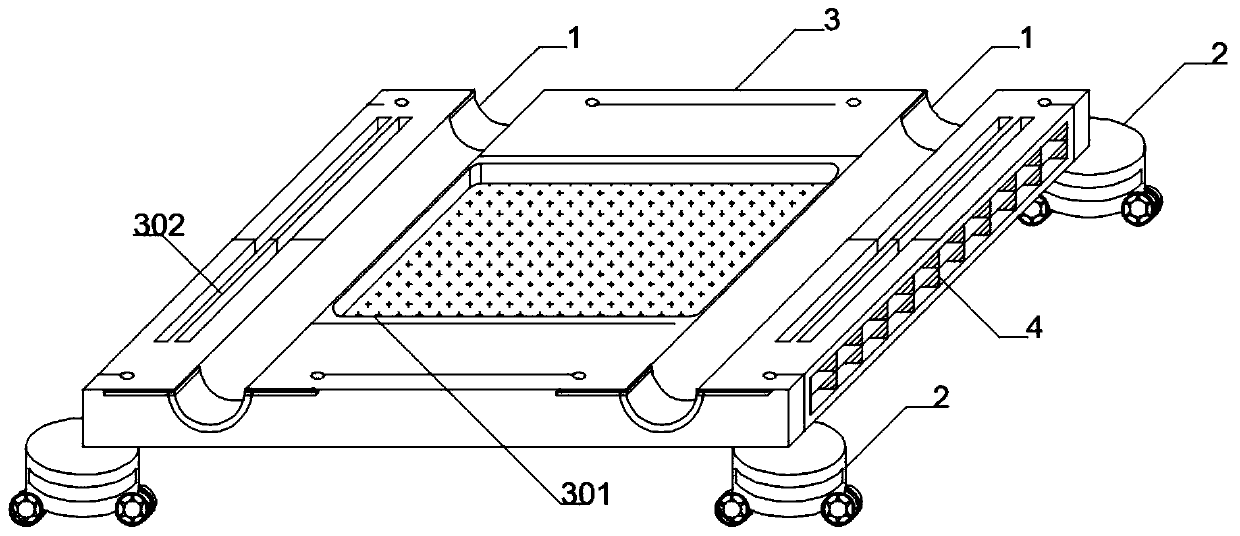

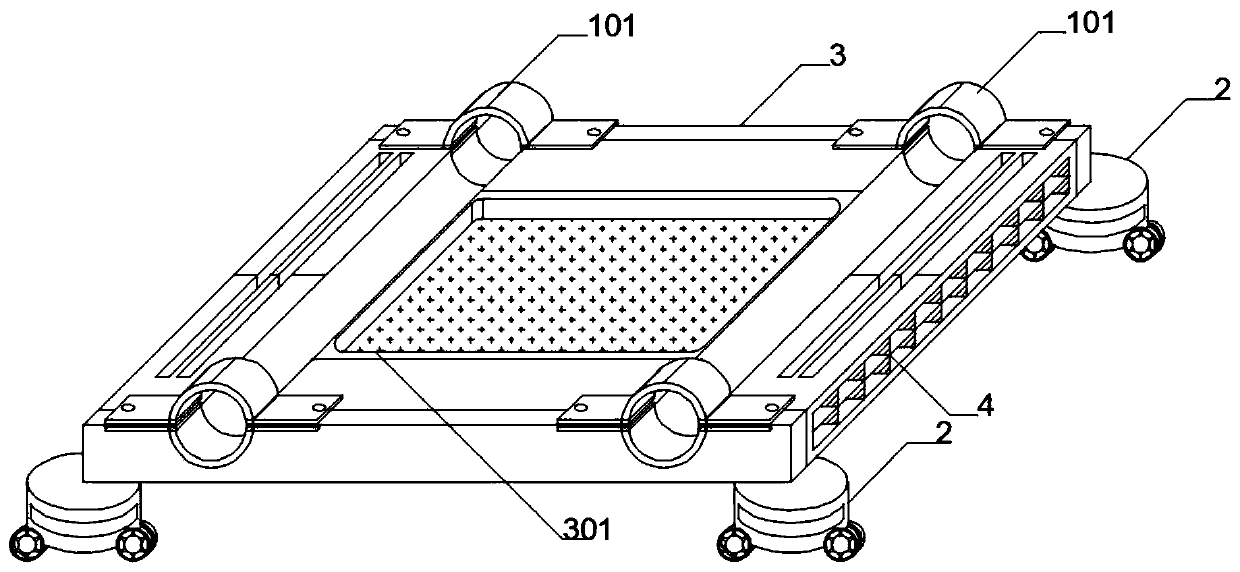

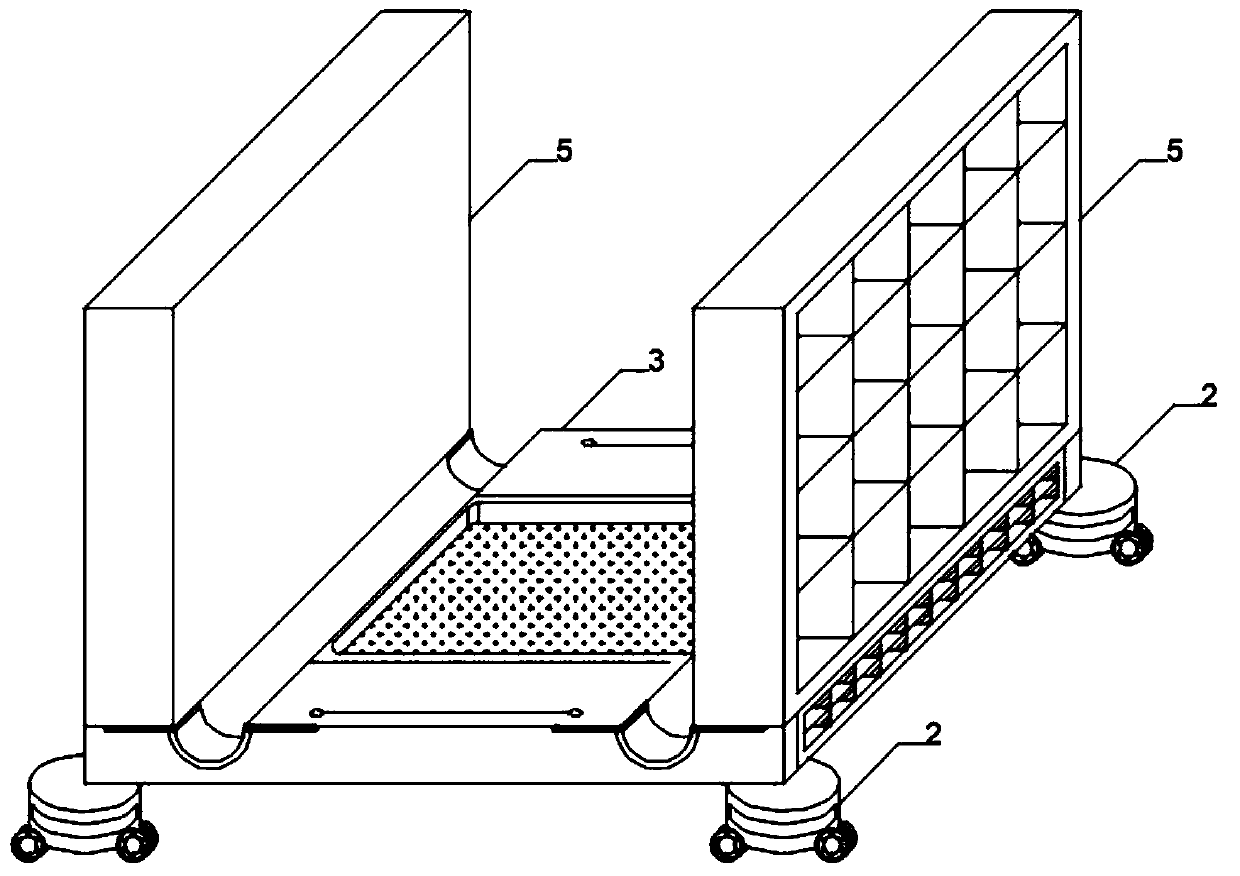

[0031] as attached figure 1 to attach Figure 5 Shown:

[0032] The present invention provides a placement rack for automobile body stamping dies, comprising a semicircular placement slot 1, a disc base 2, a supporting panel 3, a longitudinal grid 4 and an independent storage cabinet 5; the semicircular placement slot 1 is semicircular Groove structure, and a semicircle placement groove 1 is respectively provided with one on the left and right sides of the bottom of the supporting panel 3; the four corners of the bottom of the supporting panel 3 are welded and installed with a disc base 2; the supporting panel 3 A vertical grid 4 is arranged inside the edge; the independent storage cabinet 5 is an independent part.

[0033] Wherein, the semicircular placement groove 1 is a semi-cylindrical groove structure, and the left and right sides of the front and rear ends of the semicircular placement groove 1 are respectively provided with a screw hole, and the fixed outer ring 101 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com