Sheet metal forming limit research method based on heat-flow multi-field coupling

A technology of sheet forming and forming limit, which is applied in the field of sheet forming limit under the coupling effect of thermal physical field and flow field, can solve problems such as affecting the comprehensive utilization rate of materials, and achieve the effect of improving deformation flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

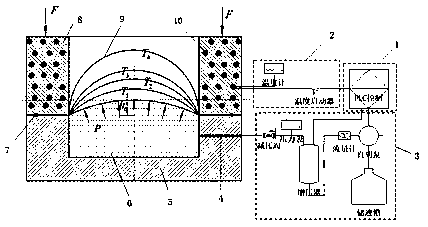

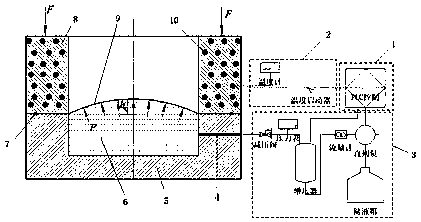

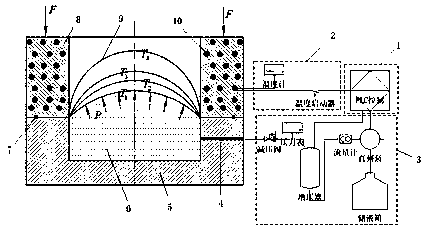

[0017] A method for researching sheet forming limit based on heat-flow multi-field coupling provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0018] Such as figure 1 — image 3 As shown, a method for researching sheet forming limit based on heat-flow multi-field coupling provided by the present invention includes the following steps in order:

[0019] 1) Connect the thermal control system 2 and the hydraulic control system 3 with the reserved interfaces of the general control system 1 respectively, and then perform system debugging under no-load conditions to ensure that each system can realize normal adjustable functions.

[0020] 2) Place the blank 9 on the lower die 5, and run the general control system 1 to realize the execution of the hydraulic control system 3. The hydraulic control system 3 feeds the fluid medium into the liquid chamber 6 through the oil inlet 4 in the lower die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com