One-side coating equipment and coating method of non-woven lithium-ion battery diaphragm

A technology for lithium ion batteries and non-woven fabrics, applied in coatings, battery pack components, and devices for coating liquids on surfaces, etc., can solve problems such as affecting the coating effect, and achieve convenient process control and reduce equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following will further clearly and completely describe the technical solutions of the present invention in conjunction with the embodiments and the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

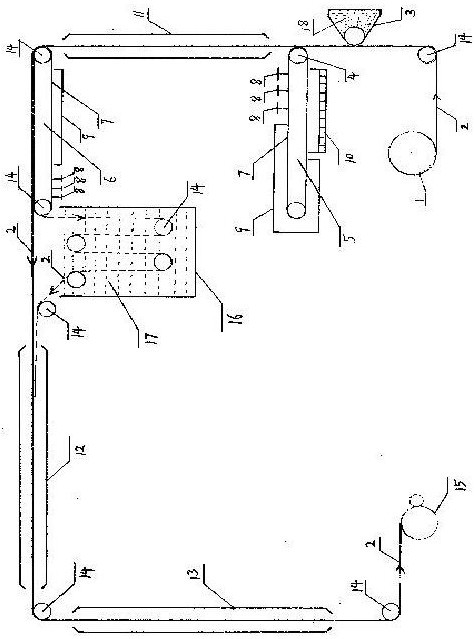

[0065] like figure 1 As shown, a non-woven lithium-ion battery separator single-sided coating equipment includes a non-woven lithium-ion battery separator 2 unwinding device 1, a dimple coating device 3, a backing roller 4, and a timing belt device I5 , synchronous belt device II6, primary drying tunnel 11, secondary drying tunnel 12, final drying tunnel 13, non-woven lithium-ion battery separator 2 winding device 15, phase inversion device 16 and cloth guide roller 14; the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com