Chromium-based metal organic skeleton composite material for adsorbing and separating palladium and preparation methods of composite material

An organic framework and composite material technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of various raw materials, poor practicability, and cumbersome steps, and achieve improved hydrodynamic properties, saving production costs, and simple operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

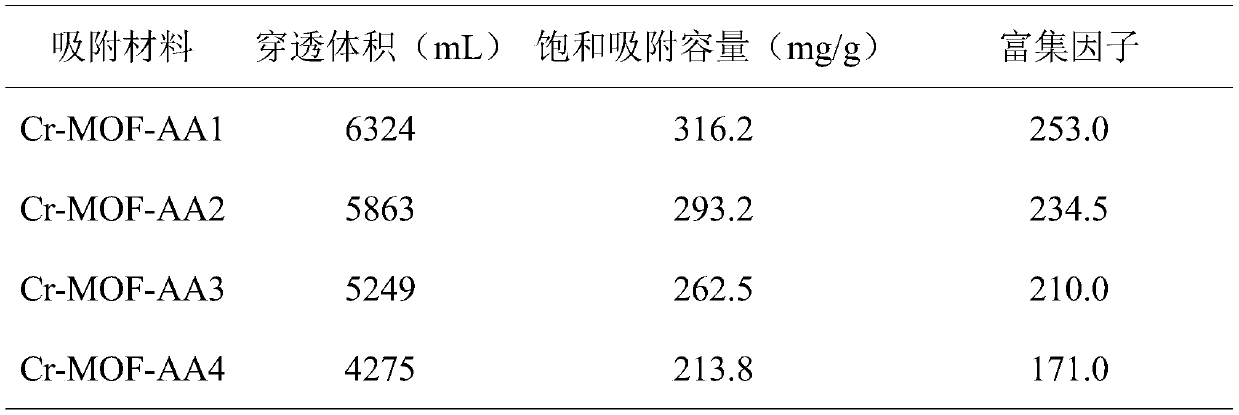

Embodiment 1

[0024] According to method A, add 12g of chromium nitrate (nonahydrate), 1.81g of 2-aminoterephthalic acid, 250mL of water and 50mL of N,N-dimethylformamide into a round-bottomed flask, mix well, and store at 150°C Stir and reflux reaction for 5 hours; after the reaction is completed, add 20 mL of sodium alginate aqueous solution with a mass concentration of 1% to the reaction mixture, stir well, then add hydrochloric acid to adjust the pH value to 1, filter with suction, and the obtained green precipitate is washed with After rinsing with liquid water, ethanol and acetone, the resulting solid was vacuum-dried at 80° C. for 6 hours to prepare a chromium-based metal-organic framework composite material, marked as Cr-MOF-AA1.

Embodiment 2

[0026] The operation steps are the same as in Example 1, the difference is that when preparing the chromium-based metal-organic framework composite material, the addition of chromium nitrate (nonahydrate) is changed to 4 g, the amount of water is changed to 100 mL, and the mass concentration of the sodium alginate aqueous solution is changed to 0.34 %, the final composite material is marked as Cr-MOF-AA2.

Embodiment 3

[0028] According to method B, 12g of chromium nitrate (nonahydrate) and 1.81g of 2-aminoterephthalic acid are added to 150mL of water, after stirring evenly, the mixed solution is transferred to a stainless steel reaction kettle equipped with a polytetrafluoroethylene liner, Let stand at 220°C for 24 hours, cool to room temperature and then centrifuge. The obtained green precipitate is soaked with washing liquid N,N-dimethylformamide and ethanol in turn, and then vacuum-dried at 150°C for 12 hours; the dried Disperse the solid in 200mL of water, disperse evenly by ultrasonic, add 20mL of sodium alginate aqueous solution with a mass concentration of 1% to the dispersion, add hydrochloric acid to adjust the pH value to 1, continue to stir for 6 hours, filter with suction, and wash the filter cake with After rinsing with liquid water, ethanol and acetone, the obtained solid was vacuum-dried at 80° C. for 6 hours to prepare a chromium-based metal-organic framework composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com