Low-density mixed material suitable for shallow loose sandstone formation, and preparation method of low-density mixed material

A low-density, loose technology, applied in the direction of chemical instruments and methods, drilling compositions, sustainable waste treatment, etc., can solve the problems of low compressive strength of cement stone, poor bonding quality of the two interfaces, etc., and achieve low water loss , meet the requirements of cementing operations, and the effect of good cementation quality of the two interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

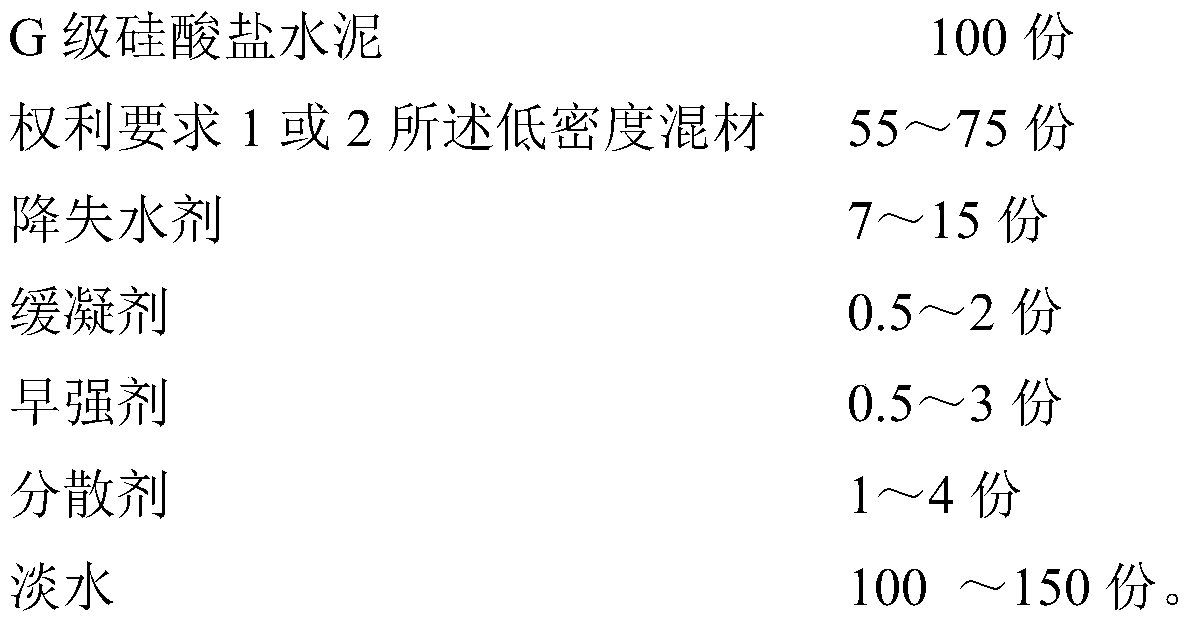

[0041] 100 parts of G-grade Portland cement, 75 parts of low-density mixed material, 13 parts of fluid loss reducer, 2 parts of retarder, 3 parts of early strength agent, 4 parts of dispersant, and 100 parts of fresh water.

[0042] The distribution ratio of the low-density mixed material components is as follows in parts by weight: 10 parts of floating beads, 40 parts of micro-silicon, 25 parts of fly ash, and 25 parts of slag.

Embodiment 2

[0044] 100 parts of G-grade Portland cement, 70 parts of low-density mixed material, 13 parts of fluid loss reducer, 2 parts of retarder, 3 parts of early strength agent, 4 parts of dispersant, and 100 parts of fresh water.

[0045] The distribution ratio of the low-density mixed material components is as follows in parts by weight: 12 parts of floating beads, 38 parts of micro-silicon, 25 parts of fly ash, and 25 parts of slag.

Embodiment 3

[0047] 100 parts of G-grade Portland cement, 64 parts of low-density mixed material, 10 parts of fluid loss reducer, 1 part of retarder, 3 parts of early strength agent, 4 parts of dispersant, and 120 parts of fresh water.

[0048] The distribution ratio of the low-density mixed material components is as follows in parts by weight: 15 parts of floating beads, 35 parts of micro silicon, 30 parts of fly ash, and 20 parts of slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com