Supersaturated sodium chloride cement slurry system for well cementation

A cementing cement slurry and sodium chloride technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of slow development of gel strength, inability to resist effectively, low early strength, etc., and achieve good salt resistance Pollution and calcium intrusion resistance, good cementing effect, and small water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

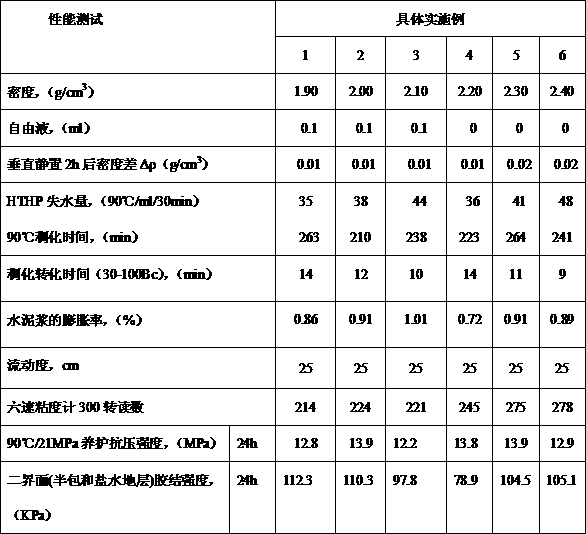

specific Embodiment 1

[0051] 100 parts of high sulfur-resistant G-grade Portland cement, 38 parts of fresh water, 10 parts of anti-salt fluid loss reducer, 8 parts of preservative, 0.5 part of anti-channeling agent, 15 parts of sodium chloride, 0.5 part of expansion agent, retarding 0.8 parts of the agent.

specific Embodiment 2

[0052] 100 parts of high sulfur-resistant G grade Portland cement, 40 parts of fresh water, 13 parts of anti-salt fluid loss reducing agent, 10 parts of preservative, 0.5 part of anti-channeling agent, 16 parts of sodium chloride, 0.5 part of expansion agent, retarding 0.8 parts of agent, 15 parts of weighting agent.

specific Embodiment 3

[0053] 100 parts of high sulfur-resistant G grade Portland cement, 45 parts of fresh water, 14 parts of anti-salt water loss reducing agent, 10 parts of preservative, 0.5 part of anti-channeling agent, 18 parts of sodium chloride, 0.5 part of expansion agent, retarding 0.6 parts of agent, 52 parts of weighting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com